Please understand that when I started this engine, we had no: computer, digital camera, and little current knowledge of the technology. Blackberries were still something we picked growing wild near our house; yum, they are good! So, all the pics posted so far, were taken with throw-away 35mm cameras, and I scanned my prints, then sized them for forum presentation, and enhanced them so they would show detail better. We did get a D. C. about 2 years ago, cheapie, which would not get in close-up; it fell off the kitchen counter about 3 months ago, and then started turning off whenever it wanted to! So, now we have a pretty good one; all future pics will be taken using the new one. However, I must apologize for the poor quality of some of the early pics, but at least you can imagine my end of this harangue- our location allows only dial-up internet service, through the local phone co. Satellite we have decided is just not within our meager budget. And, it seems, it isn't really all that fast; Hughes only GUARANTEES 108kb/sec, hell, our modem rates at half that, runs at 1/4 of that, and Hughes would cost 5 times as much! Now that you-all are bored so much the following will be ignored................

Here is a pic of the drive wheels mounted in the frames, with the side rods attached. Originally, I thought steel ground-stock would be appropriate, until it came to buying it..., I wound up using 3/8"X4" wide 6061-T651 aluminum, reasonably strong stuff, and those 2 slats are kept properly separated and aligned by 1" thick cross pieces, guess they call them "spreaders"? They are dowelled in location and later I elected to add 1/2" thick top plates which are close-fitted between the rails and spreaders, and screwed to both from the outside and through the spreaders. Sorry, I have no pics of just the frame. As stated, when this part of the project was built, I did not yet know what an Internet forum WAS, much less that I would be sticking pictures into one!

The "hornblocks" and axle boxes can be seen here. The boxes slide up & down confined within the horns by a 1/2" wide groove. I elected to use Martin Evans" suspension scheme, neglecting to incorporate equalization of springing, using individually-adjustable springs to secure even loading on drivers, thinking I could lay track good enough to get by with this. Well, it works, but sometimes rather "iffy". One's first attempt includes little knowledge of who's "expert opinion" is of true value....If someone wants to know how I "quartered" the wheels, please ask!

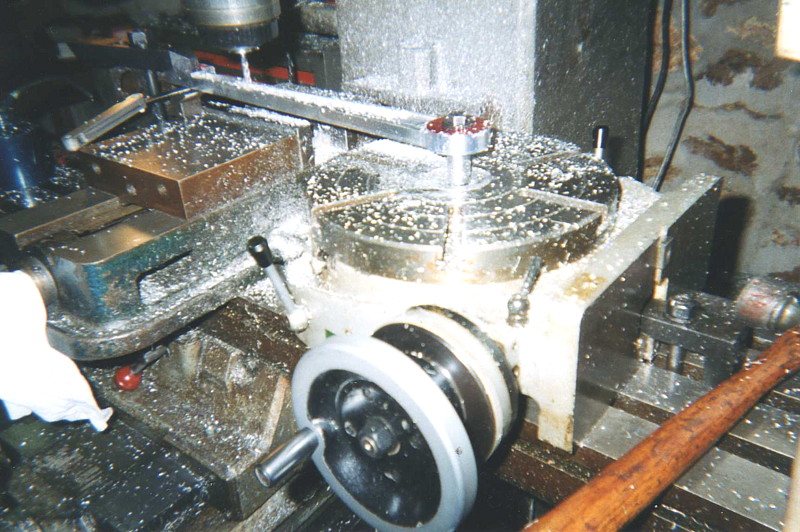

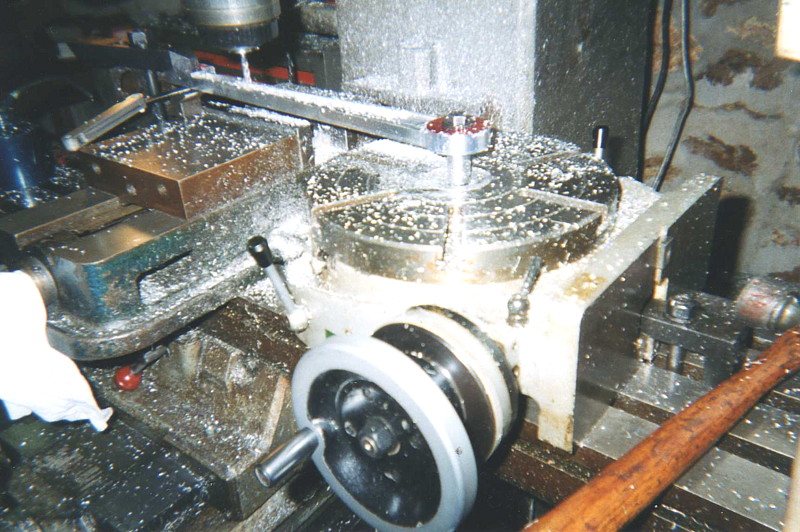

Below is a main rod being "fluted" (made to look like an I-beam cross-sectioned piece). It is bolted to a post driven into the rotary table's tapered center-hole, at it's "big end", and supported out above the vise, note the feeler-gauge stack supporting it to give rigidity for milling. This scheme allowed me to move the rod angularly by rotating the table a bit, which helps, since the rod tapers in width along it's length. This saved fastening it down, loosening, moving, locating, refastening, etc.

Here's a shot which shows fairly well, before painting, the Baker Valve Gear, and other associated parts. One of the ball bearings which support and guide the valve stem can be seen peeking through the window in the guide. Those were difficult to make, one of the most intricate parts, actually, in the whole damn locomotive! Hey, if anybody is interested, please ask about drawings, I'll be glad to post my prints of any of these parts. Beware, though, I started out gung-ho and made blue-print quality reproducibles, but toward the end, there is a stack of 8-1/2X11 sketches, even of things like the steam pump!

The crosshead consists of a hunk of 6061, also fairly involved, having 4 ball bearings, you can see the 4 hex-head screws which retain the pins they ride on, out near the corners of the head. The 4 bearings ride all in a plane, in grooves 3/16" deep in the 2 bars which are seen above and below the head. So far, after some few zillions of cycles, there is not discernible play in those bearing grooves, even though they are soft. The combination lever, and the other attached to it, whatever it's called, ride also on little ball bearings.

The "dog-leg" in the eccentric rod is....sh!t, don't ask, please! (miscalculation "fix").

And, finally, the

ultimate scrounge! Needed a small metal box, leak-tight, for oil reservoir. Sought out wife. Request made regarding maybe a spice-can? Just right! Imported Hungarian red pepper, still packaged like in the old days! Wonder WTH "SZEGED" means in Hungarian? It fastened down on top of the valve guide by little ears soldered to it's base. The cap is a flip-up plastic affair with a small hole just right for filling with a small funnel, the top actually being mostly concealed beneath the "catwalk" which ain't there yet, in the photo. The little tube feeding into the side of the smokebox carries cylinder oil to the pistons and valves. A whole story of imponderable impact lies behind the oil feed. Remind me, if I forget! For me now, it's "na ucho" after a nice cold bottle of homemade beer! See you tomorrow! jack