Maryak---If you look at my website, you will see that I teach 3D modelling.---Brian

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Learning to use CAD

- Thread starter tmuir

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Maryak

Well-Known Member

- Joined

- Sep 12, 2008

- Messages

- 4,990

- Reaction score

- 77

Brian,

Viewed your site and my congratulations on your home page.

Everything you need to go forward is there in a clear uncluttered format.

If all sites were like yours the internet would be a much easier place to surf. A lot of them make it impossible to even find the surfboard.

Thanks again for your help.

Bob

Viewed your site and my congratulations on your home page.

Everything you need to go forward is there in a clear uncluttered format.

If all sites were like yours the internet would be a much easier place to surf. A lot of them make it impossible to even find the surfboard.

Thanks again for your help.

Bob

John's point about keeping drawing to a minimum has merit for him but most of us are doing this as a hobby and not for profit. We also need "proper" drawings, a lot us us can't make something off the top of our head, so we get into cad to draw up our ideas and for that 3D minimizes work in the long run. You frequently don't even have to draw parts, they are "built in" on the higher end programs like Solidworks or Inventor. With free programs like Alibre you can download them off of the web for free.

When Boeing designed the 777 they did it all in 3d cad and started production right off the drawings with out any prototyping or mock ups to see if everything fitted right, they didn't have to.

The same applies to us. If you are making an engine or anything else to your own design, you can make sure everything is done right before you start cutting metal. This involves a lot of extra head work in 2D cad to make sure that everything is right and even then you can get half way through a part just to find out that the drawing was wrong and the part is no good (got the tee shirt for that one).

Companies don't design planes, cars, buildings or anything else in 2D anymore and once you get use to it 3D is faster in the end, but you won't learn it over night. Also don't think it is to complex for you either, they may look difficult but each individual command is quite simple and easy to use. It's all a matter of learning to use the proper command for each task and the basic ones can be learned in a few hours, the rest will take some time.

You can get books that teach most of these programs, even the free ones and there are free on line tutorials available too.

When Boeing designed the 777 they did it all in 3d cad and started production right off the drawings with out any prototyping or mock ups to see if everything fitted right, they didn't have to.

The same applies to us. If you are making an engine or anything else to your own design, you can make sure everything is done right before you start cutting metal. This involves a lot of extra head work in 2D cad to make sure that everything is right and even then you can get half way through a part just to find out that the drawing was wrong and the part is no good (got the tee shirt for that one).

Companies don't design planes, cars, buildings or anything else in 2D anymore and once you get use to it 3D is faster in the end, but you won't learn it over night. Also don't think it is to complex for you either, they may look difficult but each individual command is quite simple and easy to use. It's all a matter of learning to use the proper command for each task and the basic ones can be learned in a few hours, the rest will take some time.

You can get books that teach most of these programs, even the free ones and there are free on line tutorials available too.

rickharris

Well-Known Member

- Joined

- Jan 19, 2008

- Messages

- 313

- Reaction score

- 0

Iwould add into this that everyone can get hold of Google sketchup for free. A 3D drawing tool (I admit I can't use it but my students have produced some good effects with it.)

Replying to Loose nut's post 2 above.

I do follow where you are going and there is always two sides but it's a very fine line between spending more time doing the drawing than the part.

Now for some this can be part of the job, for others it then becomes the job.

There is no hard and fast rule but what doesn't help are these 1/2 page product reviews you see in the mags.

There has just been one in MEW on Turbocad.

Now nothing wrong with Turbocad but the writer gives the impression it's a doddle to use and any one can turn out work as shown in a matter of hours.

What they never tell you is the reviewer doesn't have a clue which end to hold a pencil and the sample shown is part of a tutorial that has taken days to prepare.

Even for retired folk, time isn't endless and there are enough constraints on it and just pointing out how you can loose time when you should be machining.

John S.

I do follow where you are going and there is always two sides but it's a very fine line between spending more time doing the drawing than the part.

Now for some this can be part of the job, for others it then becomes the job.

There is no hard and fast rule but what doesn't help are these 1/2 page product reviews you see in the mags.

There has just been one in MEW on Turbocad.

Now nothing wrong with Turbocad but the writer gives the impression it's a doddle to use and any one can turn out work as shown in a matter of hours.

What they never tell you is the reviewer doesn't have a clue which end to hold a pencil and the sample shown is part of a tutorial that has taken days to prepare.

Even for retired folk, time isn't endless and there are enough constraints on it and just pointing out how you can loose time when you should be machining.

John S.

I use Autocad in 2d, it's a tool when all said and done, if I need to set out a staircase or foundations ........... or whatever, I put enough lines on paper for me to gather enough information to set it out .............. if it's a Planning or Building Regulation submission that's a different matter ............... they need to be good quality drawings which can be read by any competent person and convey all the required information .......... plus ......... look professional to boot 8)

Horses for Courses whatever the discipline.

whatever the discipline.

CC

Horses for Courses

CC

B

Bogstandard

Guest

I have been following this from its humble beginnings, and would like to give an example and would just like to ask one question after showing a quote from Brian. Then a little resume from myself.

Now just imagine that you have never used cad in your life, and it isn't part of your work, and like maybe 95% of the members on here, either can't afford it or just don't have the wherewithall to go thru all the learning and training it involves, or just don't give a s**t, would you honestly go down the route of purchasing all that software, equipment and training to make the little engines as we do?

If you wouldn't spend all that amount, then what the hell is everyone boasting about how they use all this very expensive stuff, when it isn't in the realms of the average member on here. Interesting maybe, workable for the average guy, a definite no. So why argue about which is best or not. You use it, OK, but please don't extol the virtues to the majority who can neither afford it or have the knowledge to use it.

I have on my home made, $500, five year old computer, most probably a lot more than your basic solidworks, it runs perfectly fast enough on mine (looks like you paid a bit over the odds on that one). I wouldn't give it time of day for designing little engines. I have used it and learned a little, but for what I want to do with little engines it is the proverbial sledgehammer and nut. I am just about to get rid of it, not needed.

You might throw back at me that I have fully upgraded my shop to do just that. Wrong, I could have carried on just using the old bits and pieces I had. My new machinery will not be for model making, I will only have part time use of it for that purpose, and it was partially outside funded.

So please gents, no more boasting and elitism, just leave it at, 'well I use cad, and thats it'.

You might call me moronic and interferring for butting in, but to me this is just another elitism post that we could well do without, just like the machinery wars we used to go thru.

I could also display all my diplomas on the walls to impress, but mine are stuck up somewhere in the loft, I don't need to remind people who or what I am. I am just a nobody member, who butts in and speaks his mind and makes little engines. I like showing people how I do things, I don't pour it down their throats, but try to explain how with a little bit of thought and planning they can go up in the world of making models. Some love me, most hate me, but I just plod on until I can hold it no longer and have to speak up. This is a time I need to speak up.

One thing I really hate is a holier than thou attitude as is being shown in this post.

Actions speak louder than words, lets see a bit of action on here rather than just beating gums. This is a site dedicated to making engines, not for how much you pay for paper you use for wiping your a**e.

Upset a lot of people now haven't I?

I would just love to hear all the harrumphing and gnashing of teeth going on in the background now. 'I've been insulted' and 'harsh action' PM's flying around at the speed of light.

Been there, done that, had it done to me, got the proverbial T-shirt, but still it needed to be said.

Just come down to earth, and lets all get on with making things rather than talking about it. Otherwise, be warned, this site will end up like all the others. All talk, no action, miserable as sin, and the many being controlled by an elite few.

John

Coughed up about $6000 for solidworks and another $3000 for a computer big enough to run it, and went for the training courses that were included in that price. I love the software, and I work in Solidworks exclusively now. Heck, I even teach 3D modelling. It costs me about $1800 a year for my upgrade and software liscence

Now just imagine that you have never used cad in your life, and it isn't part of your work, and like maybe 95% of the members on here, either can't afford it or just don't have the wherewithall to go thru all the learning and training it involves, or just don't give a s**t, would you honestly go down the route of purchasing all that software, equipment and training to make the little engines as we do?

If you wouldn't spend all that amount, then what the hell is everyone boasting about how they use all this very expensive stuff, when it isn't in the realms of the average member on here. Interesting maybe, workable for the average guy, a definite no. So why argue about which is best or not. You use it, OK, but please don't extol the virtues to the majority who can neither afford it or have the knowledge to use it.

I have on my home made, $500, five year old computer, most probably a lot more than your basic solidworks, it runs perfectly fast enough on mine (looks like you paid a bit over the odds on that one). I wouldn't give it time of day for designing little engines. I have used it and learned a little, but for what I want to do with little engines it is the proverbial sledgehammer and nut. I am just about to get rid of it, not needed.

You might throw back at me that I have fully upgraded my shop to do just that. Wrong, I could have carried on just using the old bits and pieces I had. My new machinery will not be for model making, I will only have part time use of it for that purpose, and it was partially outside funded.

So please gents, no more boasting and elitism, just leave it at, 'well I use cad, and thats it'.

You might call me moronic and interferring for butting in, but to me this is just another elitism post that we could well do without, just like the machinery wars we used to go thru.

I could also display all my diplomas on the walls to impress, but mine are stuck up somewhere in the loft, I don't need to remind people who or what I am. I am just a nobody member, who butts in and speaks his mind and makes little engines. I like showing people how I do things, I don't pour it down their throats, but try to explain how with a little bit of thought and planning they can go up in the world of making models. Some love me, most hate me, but I just plod on until I can hold it no longer and have to speak up. This is a time I need to speak up.

One thing I really hate is a holier than thou attitude as is being shown in this post.

Actions speak louder than words, lets see a bit of action on here rather than just beating gums. This is a site dedicated to making engines, not for how much you pay for paper you use for wiping your a**e.

Upset a lot of people now haven't I?

I would just love to hear all the harrumphing and gnashing of teeth going on in the background now. 'I've been insulted' and 'harsh action' PM's flying around at the speed of light.

Been there, done that, had it done to me, got the proverbial T-shirt, but still it needed to be said.

Just come down to earth, and lets all get on with making things rather than talking about it. Otherwise, be warned, this site will end up like all the others. All talk, no action, miserable as sin, and the many being controlled by an elite few.

John

Wow John!!! I'm sorry if I ruffled your feathers. I was simply responding to a post that someone else started. I do not advocate the purchase of a 3D cad system to use for any home hobby. I earn my living with it. I know that there are all manner of "cheap" and "free" 3D cad systems available, but I have never tried them. If the changing marketplace hadn't demanded it, I would still be happy as a pig in mud to be working on my old drafting table. I posted what it costs me to show interested people what professional design engineering software costs. I wasn't attempting to foster any form of elitism here. I certainly wasn't trying to post a "My CAD system can beat up your CAD system" thread. Up untill now, I have enjoyed this forum. People have been fun to "talk" to, and share ideas with. Now I read your post, and I feel like I have been personally attacked! I'm off to bed now, with kind of a sour taste in my mouth. Hopefully, tomorrow will be a better day.---Brian

Im with Brian on this. I offered no slights or insult to anyone and I certainly put out my fair share of chips in my shop......If you were slighted by my attempts to be helpful by reporting my experience with my software, thats your T shirt, not mine, get over it.

The man (Tmuir) made a post about cad, started a little back and forth discussion, everyone has an opinion and they have been put forward one way or the other just like on other threads.

John Stevenson has made some valid points from his view on it, it a necessary tool that he uses as he has to, nothing more, others see it differently. I for one have been working on a long term project (life keeps getting in the way) that is fairly complex and there are no drawings available of the original that I can locate. They were produced by a company with an army of draftsmen to design and draw it. If I had to make a set of plans with only the few pictures and line drawings to work off of that I have, using their methods, I wouldn't have even attempted it. I started with a 2D program and that was painful enough but with 3D it is a go'er. Yes it takes time but so would drawing everything with a pencil at a drawing board, it's a necessary tool for me. As for posting pictures of our work it's not elitism, they were posted to show what can be done, in my case by an amateur, so others can see that it's not something beyond their ability, it's not that hard to learn.

You are wrong in the statement that this is beyond the average home shops means, free programs are widely available and are good enough for us in the same way that most of us use small simple lathes and mills to do our work instead of sophisticated CNC equipment. For many people making a good set of drawings is just as important as making the parts.

That's my opinion Bog,

If you don't like the thread don't read it.

John Stevenson has made some valid points from his view on it, it a necessary tool that he uses as he has to, nothing more, others see it differently. I for one have been working on a long term project (life keeps getting in the way) that is fairly complex and there are no drawings available of the original that I can locate. They were produced by a company with an army of draftsmen to design and draw it. If I had to make a set of plans with only the few pictures and line drawings to work off of that I have, using their methods, I wouldn't have even attempted it. I started with a 2D program and that was painful enough but with 3D it is a go'er. Yes it takes time but so would drawing everything with a pencil at a drawing board, it's a necessary tool for me. As for posting pictures of our work it's not elitism, they were posted to show what can be done, in my case by an amateur, so others can see that it's not something beyond their ability, it's not that hard to learn.

You are wrong in the statement that this is beyond the average home shops means, free programs are widely available and are good enough for us in the same way that most of us use small simple lathes and mills to do our work instead of sophisticated CNC equipment. For many people making a good set of drawings is just as important as making the parts.

That's my opinion Bog,

If you don't like the thread don't read it.

- Joined

- Sep 11, 2008

- Messages

- 115

- Reaction score

- 3

An opinion is an opinion, and one can express it weither we like it or not, that is the society we live in. I am glad we have this freedom, as it alows threads like this, but as Loose Nut says, if you don't like it, don't read it .

I started CAD about 4 years ago, bought a cheap copy and didn't know what to do with it, made some cool rectangles and stuff. Over time I taught myself how to use it to draw pictures like the ones I posted, just like I taught myself how to work a lathe amd a mill. Now it is one of my hobby's and as you can see, I draw model engines with it. It is my way to stay busy while I spend long days away from home and my main hobby...making little engines and other cool stuff that you can hold in your hands. This thread was about CAD and I answered...oh, and I have actually not printed any of these onto paper, so the computer screen might scratch a bit...

I too am off to bed, no sour taste at all and I will have a good day tomorrow...

I started CAD about 4 years ago, bought a cheap copy and didn't know what to do with it, made some cool rectangles and stuff. Over time I taught myself how to use it to draw pictures like the ones I posted, just like I taught myself how to work a lathe amd a mill. Now it is one of my hobby's and as you can see, I draw model engines with it. It is my way to stay busy while I spend long days away from home and my main hobby...making little engines and other cool stuff that you can hold in your hands. This thread was about CAD and I answered...oh, and I have actually not printed any of these onto paper, so the computer screen might scratch a bit...

I too am off to bed, no sour taste at all and I will have a good day tomorrow...

BobWarfield

Well-Known Member

- Joined

- Dec 27, 2007

- Messages

- 1,151

- Reaction score

- 1

Bogs, you're over the top on Mr Rupnow and I'd think you owe him an appology. As others have said, he only responded to the questions asked of him and did so in a good-natured and not elitist way. You've been at greater pains to document your fancy new shop (which you now say has nothing to do with models and therefore even less reason to document it) than he has his CAD, yet nobody is complaining about that. Lighten up!

RE 3D and spending more time in CAD than making parts, I can't imagine the part that I can make faster than I can draw it in my CAD program. It's one of the reasons I like Rhino so much--it's very fast once you're used to it. Even little simple things can be done very very fast (or perhaps especially simple things). That Stuart No. 1 I drew took me maybe 15 or 16 hours to draw. I had some false starts on a couple of the parts, not unlike making a mistake machining. I spent another 4 or 5 hours doing research on the Internet and scratching my head about things like slide valve timing. There's no way in heck I could machine one in 15 or 16 hours, probably even if I had both my lathe and mill converted to CNC.

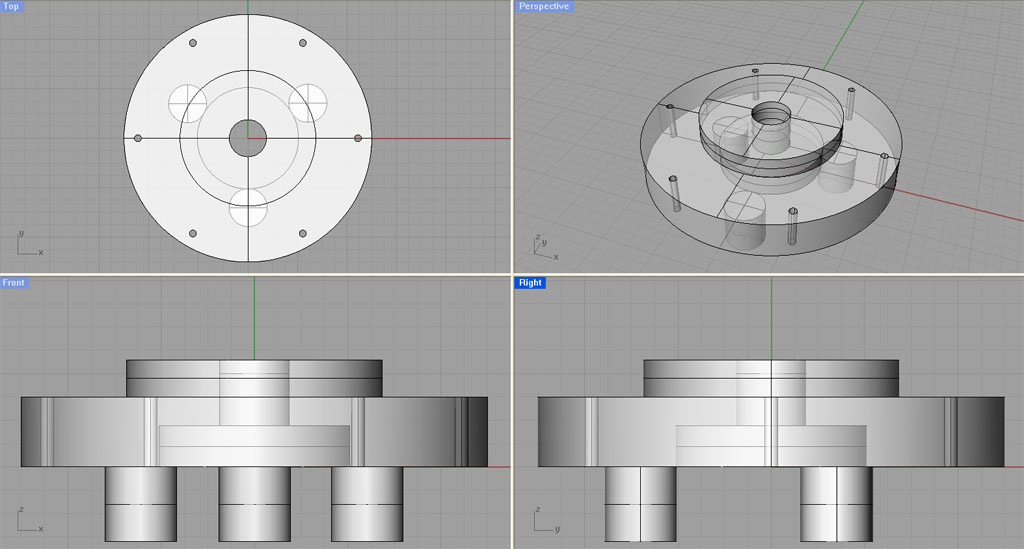

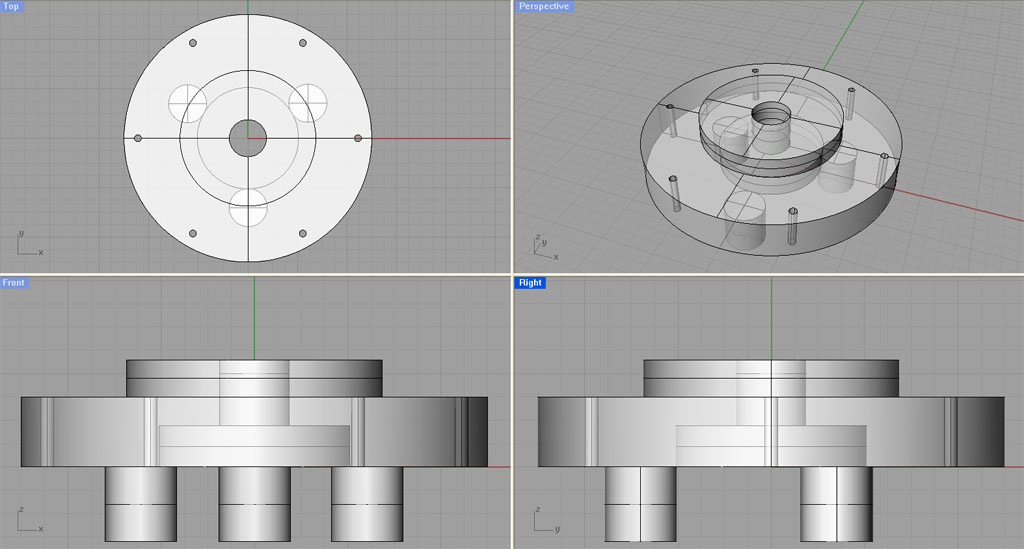

Here is the very first drawing I did in Rhino for a chuck backplate for my lathe:

I think that drawing took me maybe an hour shortly after I had bought Rhino. I was so proud of it at the time, but if you look at it, there's actually very little there. I count 13 circles, some of which required a precise 3rd dimension. Add to that some construction objects that I created but that are not shown in order to align the circles relative to one another and you've got something on the order of maybe 20 objects created. I tend to use Rhino as though I am machining objects. I know that sounds odd, but that's how I think of it. I "bore" holes by taking a cylinder as my "boring tool" and "subtracting" it from another object. That leaves a hole. I start with a big rectangular solid and subtract a smaller "cutting" object to create a groove.

Now Rhino is not a parametric modeller like Brian's Solidworks or the much cheaper Alibre. I won't explain what that means, but I did force myself to use Alibre to draw 3 or 4 complex objects, and I tried to learn it because it is more like Solidworks which is the gospel of the machine tool cad world. I just never did like it nor was I very productive. THERE IS NO RIGHT ANSWER OR PERFECT PROGRAM! Try several and force yourself to do at least 2 or 3 drawings on each. You'll figure out what you like or dislike from that, and can go from there. Maybe you grew up on 2D and prefer simpler programs. They are faster for you. Maybe you like the parameteric concept and would like Alibre. I liked Rhino.

FWIW, it costs $788 from Novedge, and can be had sometimes cheaper if you shop carefully. I got a "special deal" from a vendor and got mine for $650. As a productivity tool for my workshop, it has been worth every penny.

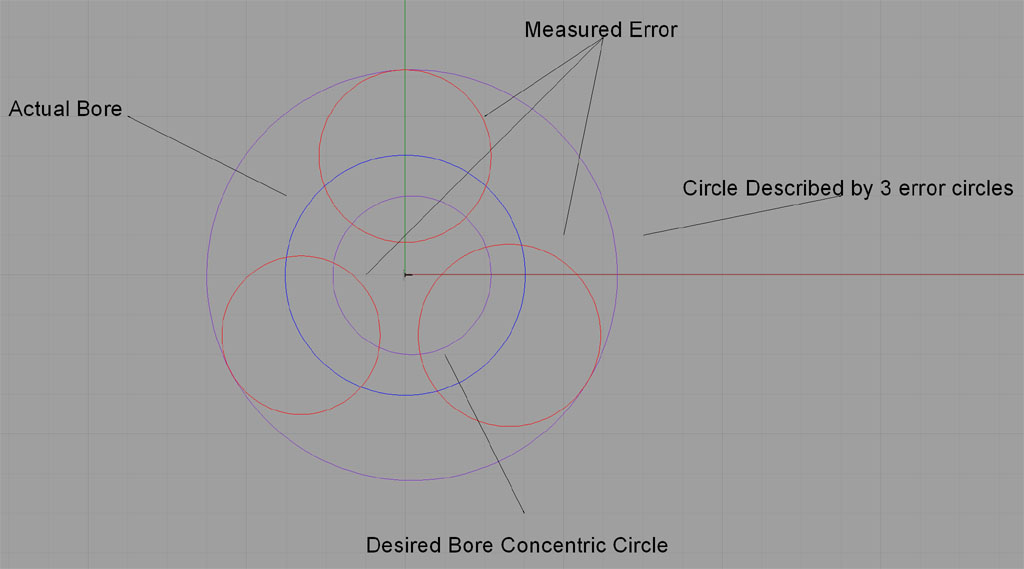

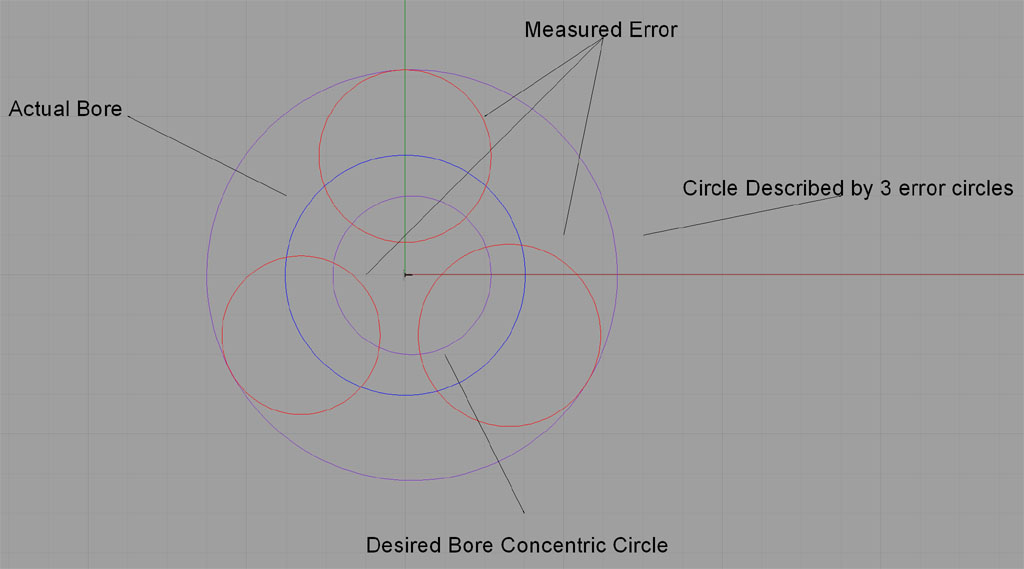

Let me leave you with a last thought. A good CAD program is more than just a way to produce drawings you can build from. It is a visual engineering calculator that is very valuable. Mine will calculate the volume of anything your draw, and you can calculate the weight of the part from that. It will tell you where the center of gravity is, which may help you figure out balance. When I was making a precision backplate for my collet chuck, I used my CAD program to help me figure out how to compensate for some machining inaccuracies on certain features. I used this diagram and some measurements on the part to figure out exactly where I was out of whack:

It enabled me to use some handwheel adjustments on the mill to offset my boring head just enough to produce a fantastically more accurate fit for the chuck. Boy was I happy with that!

As a last visual calculator use for CAD, it wasn't until I played around with various proportions in CAD that I figured out my Turner's Cube proportions and boring depths. You can see that drawing as my avatar. Also done much faster than I could have trial and errored it in real metal!

CAD. Highly recommended if not indispensible.

Cheers,

BW

PS And now the disclaimer: I am a computer scientist, I write computer software, I eat sleep drink and breathe computers. Don't be surprised if I enjoy using them here too. Your mileage may vary, and I'll be the first to admit it. It's a hobby, do what's fun and please let's not get into haranguing one another over our respective CAD programs, CAD program excesses, or lacks thereof!

RE 3D and spending more time in CAD than making parts, I can't imagine the part that I can make faster than I can draw it in my CAD program. It's one of the reasons I like Rhino so much--it's very fast once you're used to it. Even little simple things can be done very very fast (or perhaps especially simple things). That Stuart No. 1 I drew took me maybe 15 or 16 hours to draw. I had some false starts on a couple of the parts, not unlike making a mistake machining. I spent another 4 or 5 hours doing research on the Internet and scratching my head about things like slide valve timing. There's no way in heck I could machine one in 15 or 16 hours, probably even if I had both my lathe and mill converted to CNC.

Here is the very first drawing I did in Rhino for a chuck backplate for my lathe:

I think that drawing took me maybe an hour shortly after I had bought Rhino. I was so proud of it at the time, but if you look at it, there's actually very little there. I count 13 circles, some of which required a precise 3rd dimension. Add to that some construction objects that I created but that are not shown in order to align the circles relative to one another and you've got something on the order of maybe 20 objects created. I tend to use Rhino as though I am machining objects. I know that sounds odd, but that's how I think of it. I "bore" holes by taking a cylinder as my "boring tool" and "subtracting" it from another object. That leaves a hole. I start with a big rectangular solid and subtract a smaller "cutting" object to create a groove.

Now Rhino is not a parametric modeller like Brian's Solidworks or the much cheaper Alibre. I won't explain what that means, but I did force myself to use Alibre to draw 3 or 4 complex objects, and I tried to learn it because it is more like Solidworks which is the gospel of the machine tool cad world. I just never did like it nor was I very productive. THERE IS NO RIGHT ANSWER OR PERFECT PROGRAM! Try several and force yourself to do at least 2 or 3 drawings on each. You'll figure out what you like or dislike from that, and can go from there. Maybe you grew up on 2D and prefer simpler programs. They are faster for you. Maybe you like the parameteric concept and would like Alibre. I liked Rhino.

FWIW, it costs $788 from Novedge, and can be had sometimes cheaper if you shop carefully. I got a "special deal" from a vendor and got mine for $650. As a productivity tool for my workshop, it has been worth every penny.

Let me leave you with a last thought. A good CAD program is more than just a way to produce drawings you can build from. It is a visual engineering calculator that is very valuable. Mine will calculate the volume of anything your draw, and you can calculate the weight of the part from that. It will tell you where the center of gravity is, which may help you figure out balance. When I was making a precision backplate for my collet chuck, I used my CAD program to help me figure out how to compensate for some machining inaccuracies on certain features. I used this diagram and some measurements on the part to figure out exactly where I was out of whack:

It enabled me to use some handwheel adjustments on the mill to offset my boring head just enough to produce a fantastically more accurate fit for the chuck. Boy was I happy with that!

As a last visual calculator use for CAD, it wasn't until I played around with various proportions in CAD that I figured out my Turner's Cube proportions and boring depths. You can see that drawing as my avatar. Also done much faster than I could have trial and errored it in real metal!

CAD. Highly recommended if not indispensible.

Cheers,

BW

PS And now the disclaimer: I am a computer scientist, I write computer software, I eat sleep drink and breathe computers. Don't be surprised if I enjoy using them here too. Your mileage may vary, and I'll be the first to admit it. It's a hobby, do what's fun and please let's not get into haranguing one another over our respective CAD programs, CAD program excesses, or lacks thereof!

Maryak

Well-Known Member

- Joined

- Sep 12, 2008

- Messages

- 4,990

- Reaction score

- 77

As a new member I was disappointed to read bogstandard's post. Bog you've already given me encouragement with my project as has Brian with his helpful comments re 3D Cad.

This forum is a great place, in fact I'd go as far as saying it's the best I've been associated with and that after one week! This appears to be the 1st incident of uncalled for comment. Let's hope it's the last.

If you can't be nice, be neutral, if you can't be neutral, be constructive, else don't post.

This forum is a great place, in fact I'd go as far as saying it's the best I've been associated with and that after one week! This appears to be the 1st incident of uncalled for comment. Let's hope it's the last.

If you can't be nice, be neutral, if you can't be neutral, be constructive, else don't post.

B

Bogstandard

Guest

Now I see whom I have upset.

To the first major point I would like to answer.

'You don't have to read it.' - I do!! That is my choice, and no one will stop me reading anything on this sight that I want to.

If it is about raising marigolds or the Titanic, I read every word of every post. I am not on the admin team so cannot do anything about anything, except to raise an issue.

If you read my post it wasn't about using CAD at all, that is your choice, if that is the way you wish to carry on making engines and bits.

Imagine me saying to anyone on here, I can make my bits better because I have XYZ machinery and I'm the greatest. If you can't afford this, you will never get to my standards, and because you haven't got XYZ machinery, you will never make it any better.

To me that is elitism, and I am sorry if I have upset anyone over this issue, but my statements stand.

I said you would throw this at me, and as I stated it is a production workshop, funded partly by outside means. But if you notice with my posts, it isn't all about cost and flaunting it, it is showing how I set up a new workshop, with ideas on how everyone else could, even with the most meagre of machines produce a better finished article, and have a more efficient workshop setup. No way have I said anywhere that this is what is needed to produce little engines. If that still remains an issue with you, consider that post now fully closed. Not thru spite or malice, but you have raised an issue and I am responding to it in the only way I know how.

Thank you, that is exactly what I have been on about.

I WILL NOT be told by anyone what and what I cannot bring to the fore on any posting.

How can you be neutral when there is blatent elitism being shown to other members? Someone has to speak up, otherwise the site will become a free for all for 'holier than thouists, and I've got this, and it is better than yours'

Nowhere in my post did I mention that the average home shop couldn't afford the CAD programs as you quote.

I am on about the statement by Bob about how much it has cost him overall, and into the future. A little different than freebies and lo cost software.

So gents, like my reply or not, I have had my say and responded to your queries and statements. If you want to carry on, I have all the time in the world at my disposal to argue with you, and fully enjoy it at times.

I have nothing more to say, unless you want to carry it on.

John

To the first major point I would like to answer.

'You don't have to read it.' - I do!! That is my choice, and no one will stop me reading anything on this sight that I want to.

If it is about raising marigolds or the Titanic, I read every word of every post. I am not on the admin team so cannot do anything about anything, except to raise an issue.

If you read my post it wasn't about using CAD at all, that is your choice, if that is the way you wish to carry on making engines and bits.

Imagine me saying to anyone on here, I can make my bits better because I have XYZ machinery and I'm the greatest. If you can't afford this, you will never get to my standards, and because you haven't got XYZ machinery, you will never make it any better.

To me that is elitism, and I am sorry if I have upset anyone over this issue, but my statements stand.

You've been at greater pains to document your fancy new shop (which you now say has nothing to do with models and therefore even less reason to document it) than he has his CAD, yet nobody is complaining about that. Lighten up!

I said you would throw this at me, and as I stated it is a production workshop, funded partly by outside means. But if you notice with my posts, it isn't all about cost and flaunting it, it is showing how I set up a new workshop, with ideas on how everyone else could, even with the most meagre of machines produce a better finished article, and have a more efficient workshop setup. No way have I said anywhere that this is what is needed to produce little engines. If that still remains an issue with you, consider that post now fully closed. Not thru spite or malice, but you have raised an issue and I am responding to it in the only way I know how.

It's a hobby, do what's fun and please let's not get into haranguing one another over our respective CAD programs, CAD program excesses, or lacks thereof!

Thank you, that is exactly what I have been on about.

If you can't be nice, be neutral, if you can't be neutral, be constructive, else don't post.

I WILL NOT be told by anyone what and what I cannot bring to the fore on any posting.

How can you be neutral when there is blatent elitism being shown to other members? Someone has to speak up, otherwise the site will become a free for all for 'holier than thouists, and I've got this, and it is better than yours'

You are wrong in the statement that this is beyond the average home shops means, free programs are widely available and are good enough for us in the same way that most of us use small simple lathes and mills to do our work instead of sophisticated CNC equipment.

Nowhere in my post did I mention that the average home shop couldn't afford the CAD programs as you quote.

Quote

Coughed up about $6000 for solidworks and another $3000 for a computer big enough to run it, and went for the training courses that were included in that price. I love the software, and I work in Solidworks exclusively now. Heck, I even teach 3D modelling. It costs me about $1800 a year for my upgrade and software liscence

Now just imagine that you have never used cad in your life, and it isn't part of your work, and like maybe 95% of the members on here, either can't afford it or just don't have the wherewithall to go thru all the learning and training it involves, or just don't give a s**t, would you honestly go down the route of purchasing all that software, equipment and training to make the little engines as we do?

If you wouldn't spend all that amount, then what the hell is everyone boasting about how they use all this very expensive stuff, when it isn't in the realms of the average member on here. Interesting maybe, workable for the average guy, a definite no. So why argue about which is best or not. You use it, OK, but please don't extol the virtues to the majority who can neither afford it or have the knowledge to use it.

I am on about the statement by Bob about how much it has cost him overall, and into the future. A little different than freebies and lo cost software.

So gents, like my reply or not, I have had my say and responded to your queries and statements. If you want to carry on, I have all the time in the world at my disposal to argue with you, and fully enjoy it at times.

I have nothing more to say, unless you want to carry it on.

John

John, what Brian said is valid, he bought SW to earn a living and that's what he was forced to do by circumstances and customers.

It's no different from your workshop post where you admit that the machines are for production use.

How many think you are now the elitist one ? and if you say you are not they why didn't you keep your original machines to do what you planned?

Chances are they wouldn't have done the work just as Brian's blunt pencil won't scratch the paper with new customers

Many choices were put forward from Free versions of Solid Edge and Alibre to relatively cheap Rhino to just using 2D CAD from whatever source.

Brian's post was only one

BTW anyone thinking about setting a workshop up, MEW have brought a special out, only available from them or W.H. Smiths [ a Barnes and Noble store for the cousins ]

It gives a good insight on machine tools, hand tools, wiring, insurance, security and many more subjects.

It's well written and put together with no bias on any one supplier or product, woth getting a copy for a fiver, even if you have a workshop setup it's still a good read.

It's no different from your workshop post where you admit that the machines are for production use.

How many think you are now the elitist one ? and if you say you are not they why didn't you keep your original machines to do what you planned?

Chances are they wouldn't have done the work just as Brian's blunt pencil won't scratch the paper with new customers

Many choices were put forward from Free versions of Solid Edge and Alibre to relatively cheap Rhino to just using 2D CAD from whatever source.

Brian's post was only one

BTW anyone thinking about setting a workshop up, MEW have brought a special out, only available from them or W.H. Smiths [ a Barnes and Noble store for the cousins ]

It gives a good insight on machine tools, hand tools, wiring, insurance, security and many more subjects.

It's well written and put together with no bias on any one supplier or product, woth getting a copy for a fiver, even if you have a workshop setup it's still a good read.

B

Bogstandard

Guest

John,

If I didn't have to upgrade to carry out contract work (which my old machines were not capable of) I would have kept the old shop and all machines in it, as I have stated elsewhere on this site.

I have used the information on the rebuild of my shop to help people in giving people ideas about how they could improve theirs (NOT MACHINE UPGRADES) and how I go about setting up machines to get the best out of them. Not flaunting it, but using them as an example. Unlike our friend who seems to think that everyone should know how much it costs, even down to yearly licensing costs.

If my post is classed as elitism, then so be it, the problem you and others have with that is now solved. Well before you made your post.

A decision I have made to stop any confusion over the issue.

John

If I didn't have to upgrade to carry out contract work (which my old machines were not capable of) I would have kept the old shop and all machines in it, as I have stated elsewhere on this site.

I have used the information on the rebuild of my shop to help people in giving people ideas about how they could improve theirs (NOT MACHINE UPGRADES) and how I go about setting up machines to get the best out of them. Not flaunting it, but using them as an example. Unlike our friend who seems to think that everyone should know how much it costs, even down to yearly licensing costs.

If my post is classed as elitism, then so be it, the problem you and others have with that is now solved. Well before you made your post.

A decision I have made to stop any confusion over the issue.

John

"If I didn't have to upgrade to carry out contract work (which my old machines were not capable of) I would have kept the old shop and all machines in it, as I have stated elsewhere on this site."

That was Brian's point also, He made that clear.

That was Brian's point also, He made that clear.

Really, I lied. I only paid 47 cents for my CAD system, and I only use it to draw pictures of my cat!!! Are Ya happy now??? Do ya like me better now??? Hope this makes you feel better now!!! There is obviously something wrong in your world.---Brian

SmoggyTurnip

Well-Known Member

- Joined

- Mar 12, 2008

- Messages

- 106

- Reaction score

- 0

I thought Brians post was informative, intresting and on topic. - It's also nice to know how much Cad software costs - the thread was interesting.

Similar threads

- Replies

- 2

- Views

- 625

- Replies

- 13

- Views

- 638

- Replies

- 180

- Views

- 23K