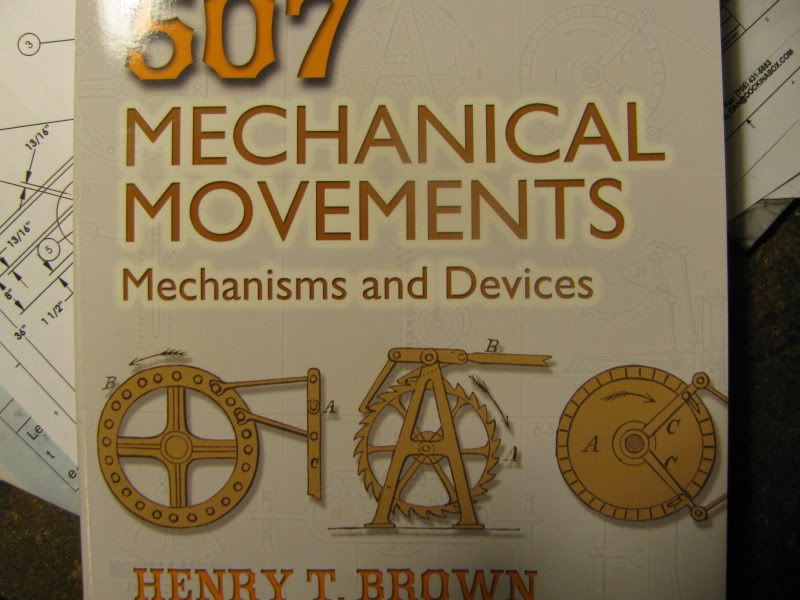

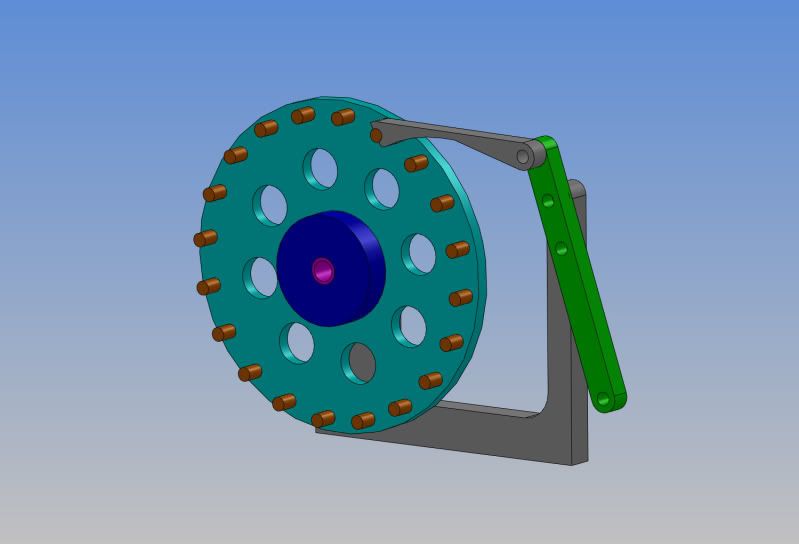

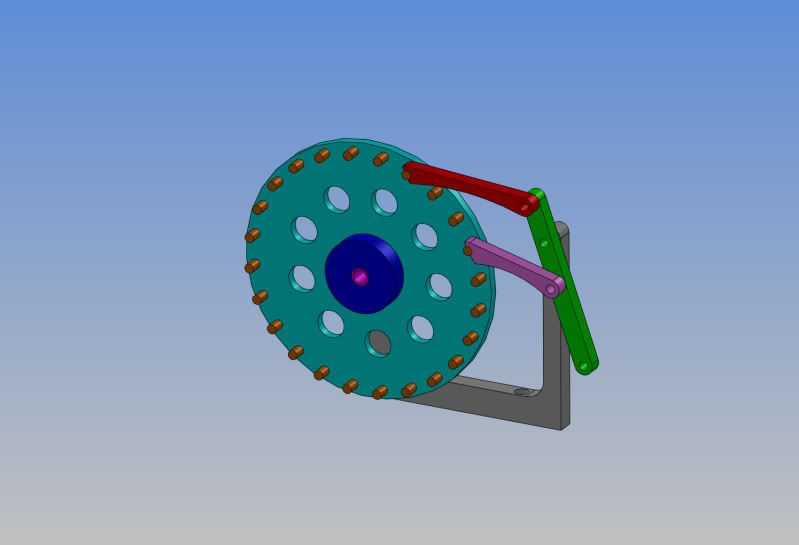

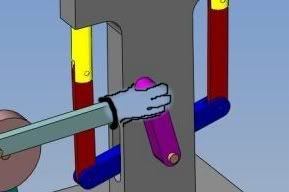

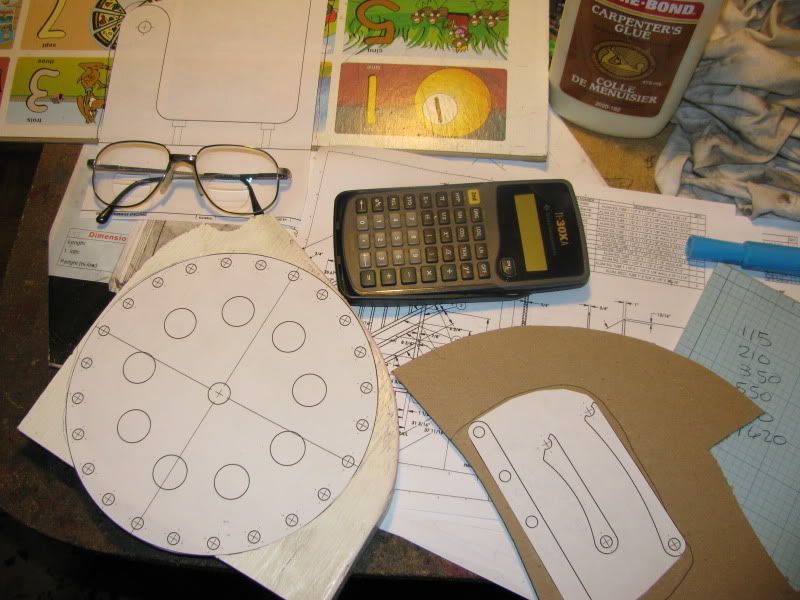

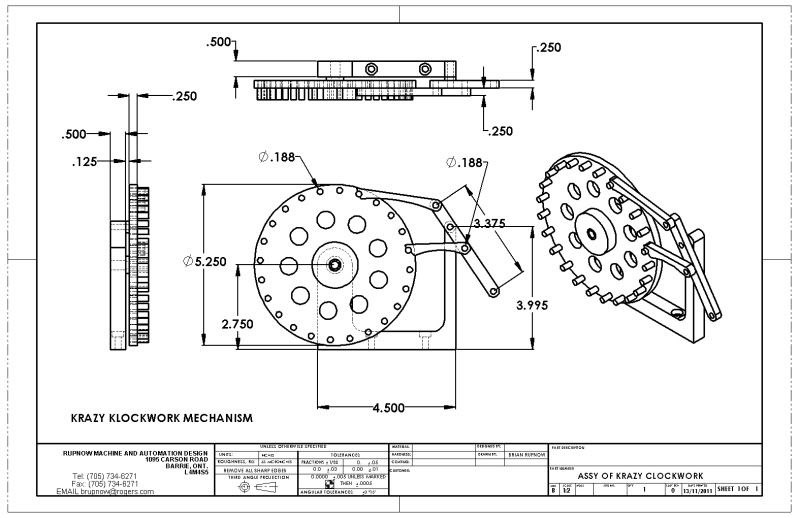

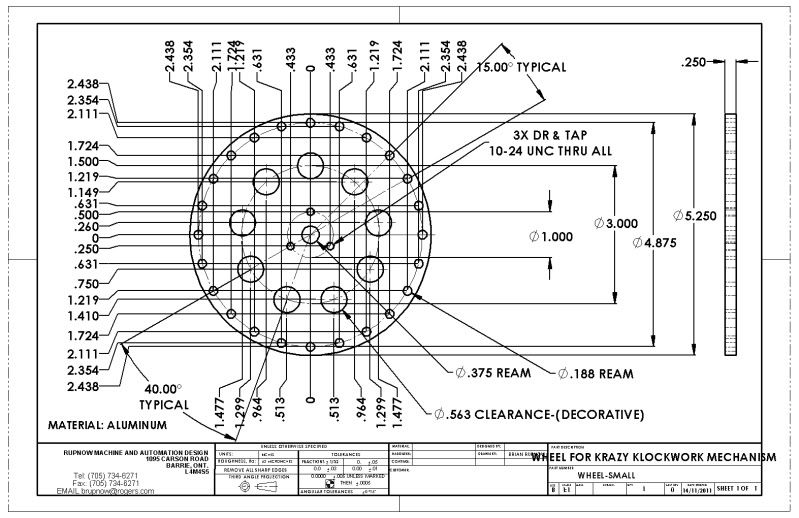

Last year for my birthday, my daughter bought me this book, "507 Mechanical Movements" by Henry T Brown. Its been a month now since I finished my build of the Popcorn engine, and I've recovered enough to start thinking about another machining project. I am always on the lookout for amusing things to run with my various collection of model steam and gasoline engines, and I may have found another. The picture on the left has a neat looking SOMETHING!!! I don't really know what its called, but it kind of looks like a clockwork mechanism, thus my threads title. I really have nothing to go on here except for the picture, and a very brief explanation of how it works in the book. As the bar "C" rocks back and forth on pivot "A", the "arms" (for lack of a better word) engage the posts on the wheel "B" and give it an "Almost continuous rotation"-----At least thats what the book says. I'm thinking an aluminum wheel about 6" in diameter, with brass "posts". I will design it first in Solidworks, and post the drawings as I go along, as usual. Driven by a small steam engine, it ought to look pretty neat!!!----Brian