I made four support columns for the table using some ¾ hex brass. The ends have a 0.020 register on both ends that fit in recesses in the table and base. Both ends of the columns are tapped ¼ 20 for mounting hardware. Note the hex head screws will eventually be replaced with finials made from hex brass stock.

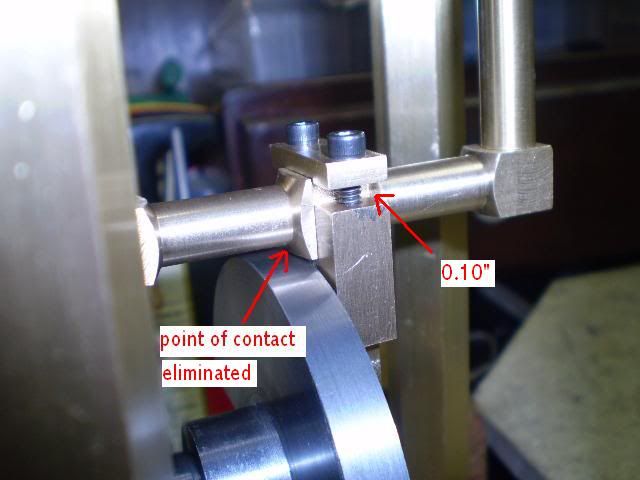

When I assembled the table to the base using the columns I made a trial fit of the con rod assembly through the table slots. I could have done this sooner, but I discovered that the arms of the con rod assembly were too close together and were wedged up against the slots in the table. This was not a design error. If I had followed the plans for the con rod arms, I would have had clearance.

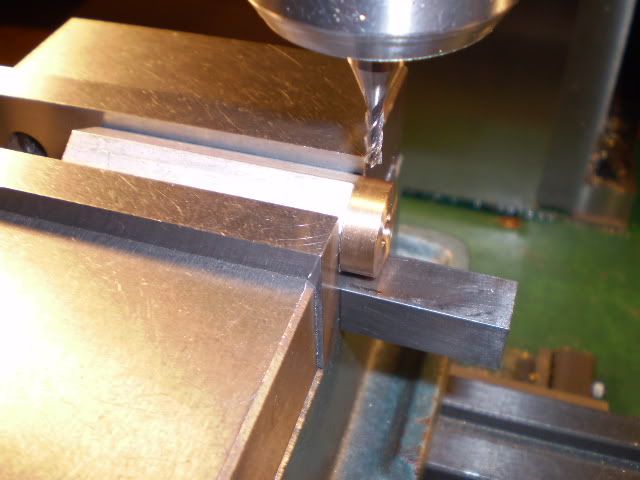

Now decision time widen the table slots by about 0.025 or make a new con rod crossarm. I decided to make a new crossarm. First of all, I wanted to make a recess in the center of it to fit the journal. That would prevent any lateral movement of the journal.

Secondly, later on Im going to pin these joints with taper pins. Ive never used taper reamers so I can use the old crossarm to practice.

The only complication with making the recess on the crossarm was gripping the workpiece to turn down the second side of the arm. I had to grip the workpiece on the 0.450 square end which is only ½ long and that leaves me with quite a bit of overhang. My other option would have been to make a split ring and grip the round part of the arm in a 3 jaw chuck. I decided to risk the overhang and take light cuts and that worked out OK.

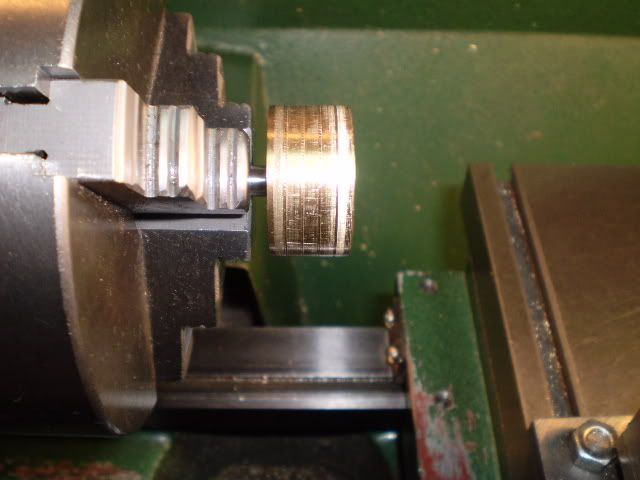

I made a packing gland from some ¾ bronze. Turned the required length of the gland to a diameter of 0.730. Then turned a length of 0.613 to a diameter of 0.494. Using the tailstock dieholder I turned ½ 20 NF threads on the workpiece. Except, my diameter was too high (0.495) and I couldnt cut to the shoulder. Plus the threads got buggered which has been my experience when I try to cut them on a diameter thats too high.

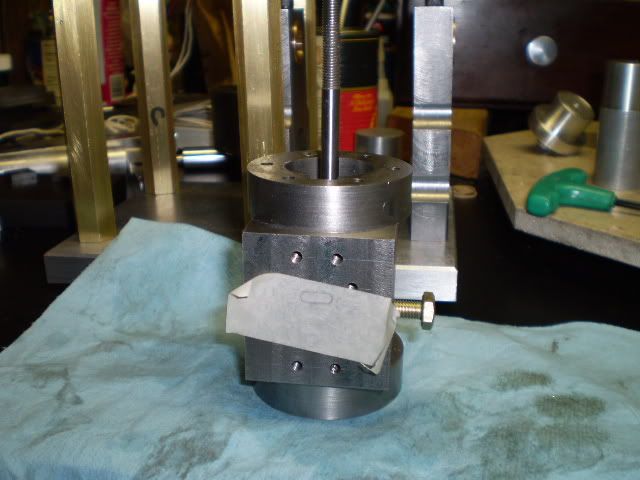

I made a second gland by turning the threaded part down to 0.484 and had no trouble. I drilled a clearance hole in the workpiece with an F (0.257) drill. Parted off the workpiece. I had a piece of ¾ aluminum hex bar that had been drilled/tapped ½ 20 from making packing glands for other engines. I screwed the packing gland into the fixture and faced the gland to its required length. Then I drilled six holes using a 1/8 end mill. The hex fixture makes this a simple procedure.

With the gland held in the three jaw chuck of the lathe and the upper cylinder head screwed on, the TIR on the rim of the cylinder head was 0.015. Not very good, but I expected as much at this point.

Both ends of the gland had been faced off before any of the other machining operations. But under magnification its apparent that thread cutting produced a significant burr on that end of the workpiece. This end butts up against the bottom of the threaded hole in the cylinder head. So off to my surface plate with some #500 grit paper to polish the threaded end, and wire brush the threads. Then a thorough cleaning of the bottom of the threaded hole in the head. Reassemble, and measure TIR on the rim 0.004. That seems acceptable from my past experience with an engine of these dimensions.

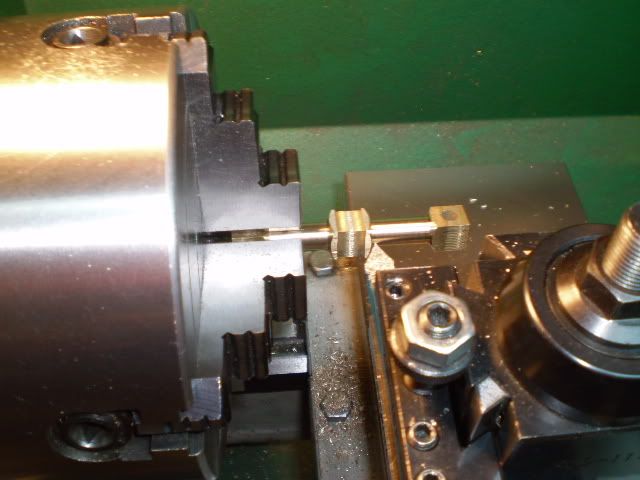

The piston rod was made from a piece of ¼ drill rod. Each end was to be threaded ¼ 28 NF. I turned the diameter down to 0.240 on both ends for the section to be threaded. Then, using a tailstock dieholder I made, threads were cut to a length of 0.625 on the piston end and 1.250 on the crosshead end.

I used a piece of aluminum bronze to make the piston. After facing, I turned the diameter to 1.250. The cylinder bore is 1.200 and the piston will be turned to fit the bore once its installed on the piston rod. I drilled it with a #3 drill for ¼ 28 NF threads. Then I faced the other end for an OAL of 0.625. Threads were cut by using a diestock held up against the face of the drill chuck in the tailstock. Once started this way, the threads were cut through the piston blank.

The piston rod was held in the 3 jaw chuck on the lathe and the piston screwed on tightly. I measured TIR of 0.003 on the piston. This measurement tells me that cutting the threads on the piston rod and piston went reasonably well. Once the piston was turned to its final size, TIR was about 0.000.

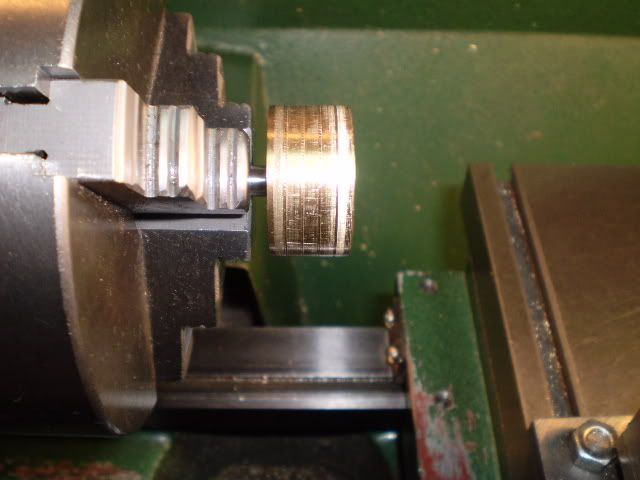

I had an aluminum dowel of diameter 1.201 which I thought was a fairly good fit in the bore. I decided to turn the piston to 1.202 for a trial fit. I managed to nearly hit that diameter but the piston wouldnt clear the bore. I gave it a few light polishes with some #500 sandpaper until it could fully enter both ends of the cylinder. Then I cut 4 oil grooves 0.004 deep using an E4 toolbit. A final deburring, and the piston seems a good fit in the cylinder, not too loose, not too tight.

To test the fit I placed a piece of tape across the steam ports, and closed off the exhaust port and put the cylinder on a piece of oiled paper. If the piston crashed to the bottom its too loose, then Id have to start over. If it didnt descend it would need a bit of polish. The piston very slowly descended under its own weight so I think I have a winner. Though I can explain what I did in a few sentences it took me a number of hours to finish the piston to my satisfaction. Lots of light cuts and deburring near the end.

At this point I have all the parts needed to test the function of 3 assemblies Ive made. I took the cylinder and attached the upper head, crosshead base and rails. I poked the piston rod with piston attached through the upper head and attached it to the crosshead.

Movement of the crosshead is slightly tight but its what I would call ready to be worked in. So, Im ready to make the crankshaft and test the fit of the con rod assembly.

This is going to be a tall engine 18+ inches.

Cheers,

Phil