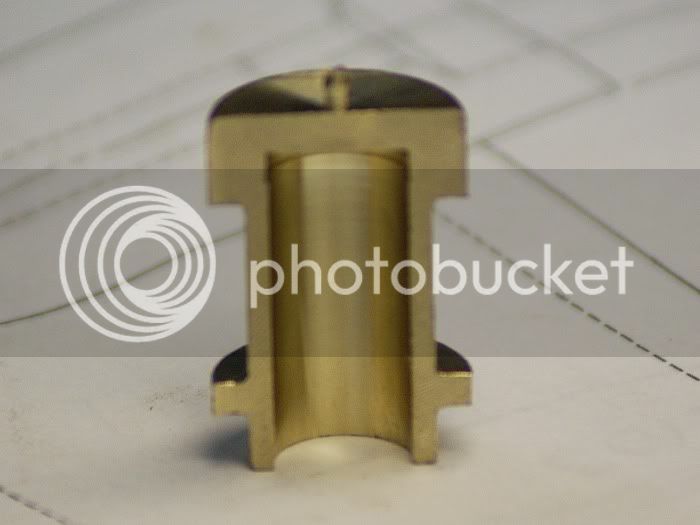

I've been working on mounting my 5C collet chuck. The other thing I did was to experiment with polishing the brass for the flywheels, and with "bumping the tool" to keep it's diameter accurate along a long piece of brass. Lastly, now that the collet chuck is more or less working, I've been trying it out on the flywheels and thinking of various "mass production" techniques. Frankly, I could just make them all as one offs, but I wanted to fool around with it a bit more.

Since this is my first experience with 5C collets on the lathe, I am learning some things, not all of them helpful, but all things I need to be aware of to succeed. The chuck is extremely accurate, and I love the ability to take a part out for measurement and put it back quickly and accurately. Very cool! On the negative front, while collets are supposed to be non-marring, they aren't. After a little research I discovered you can get nylong 5C's that would be. The other one that's been vexing me is that the workpiece moves in length as you tighten the collet. This makes it hard to use work stops as effectively as I had hoped.

I did one quick flywheel, start to finish including the reamed hub and it looks good. I may just get going doing them individually without further "mass production" experiments. The con rod will be harder. Been thinking about it a lot. I'll probably use collets for it too.

Best,

BW