Steve--I don't know what is going on. Your plugs fire fine when laying out on the cylinder, and I have no real reason to believe that they aren't firing under compression. I'm trying hard to figure out what is happening. I've tried both the plugs you sent me with no difference in what is going on. Something is happening that I don't understand. I will find my way thru it, I don't think that the problem is with your sparkplugs.---Brian

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

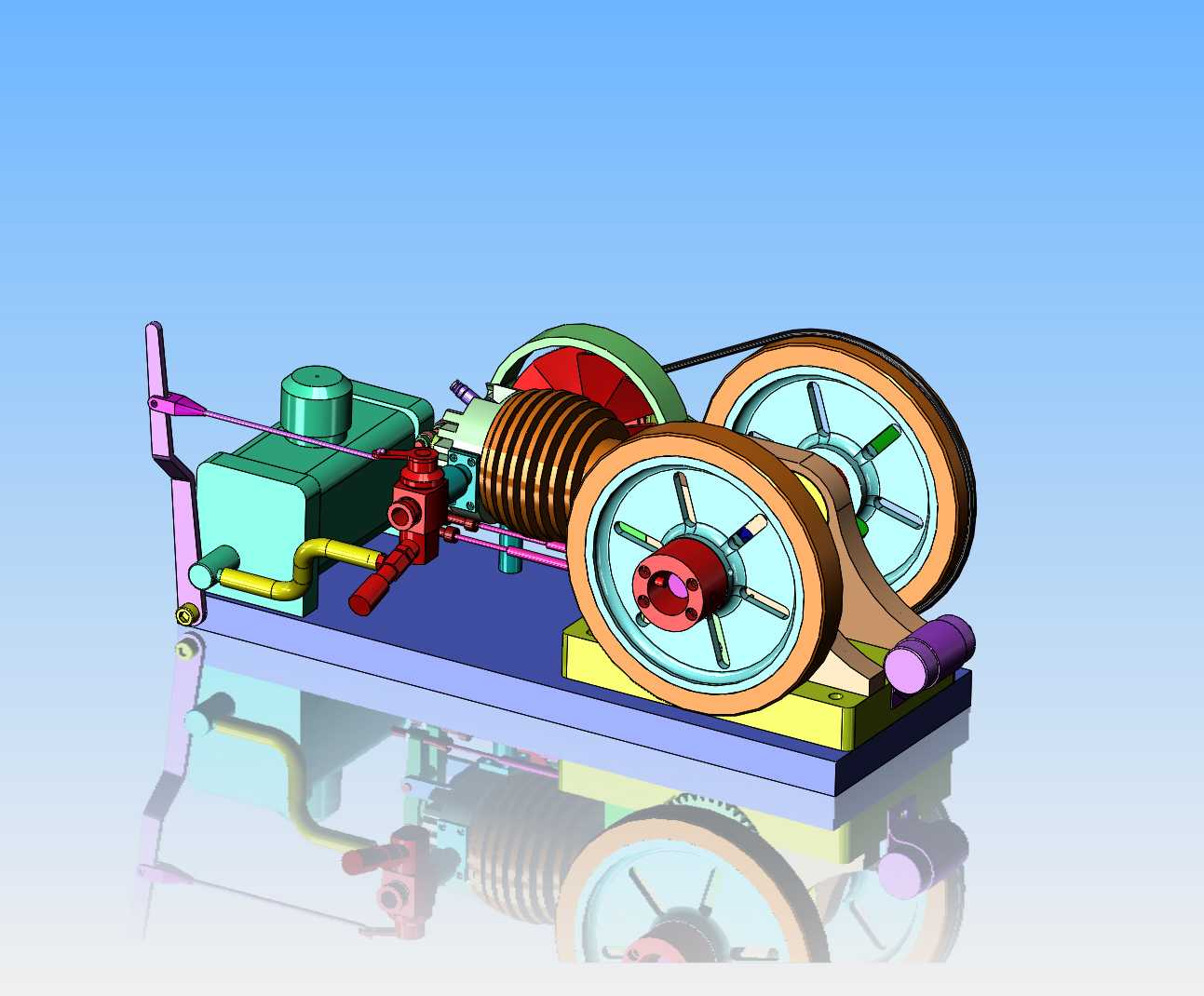

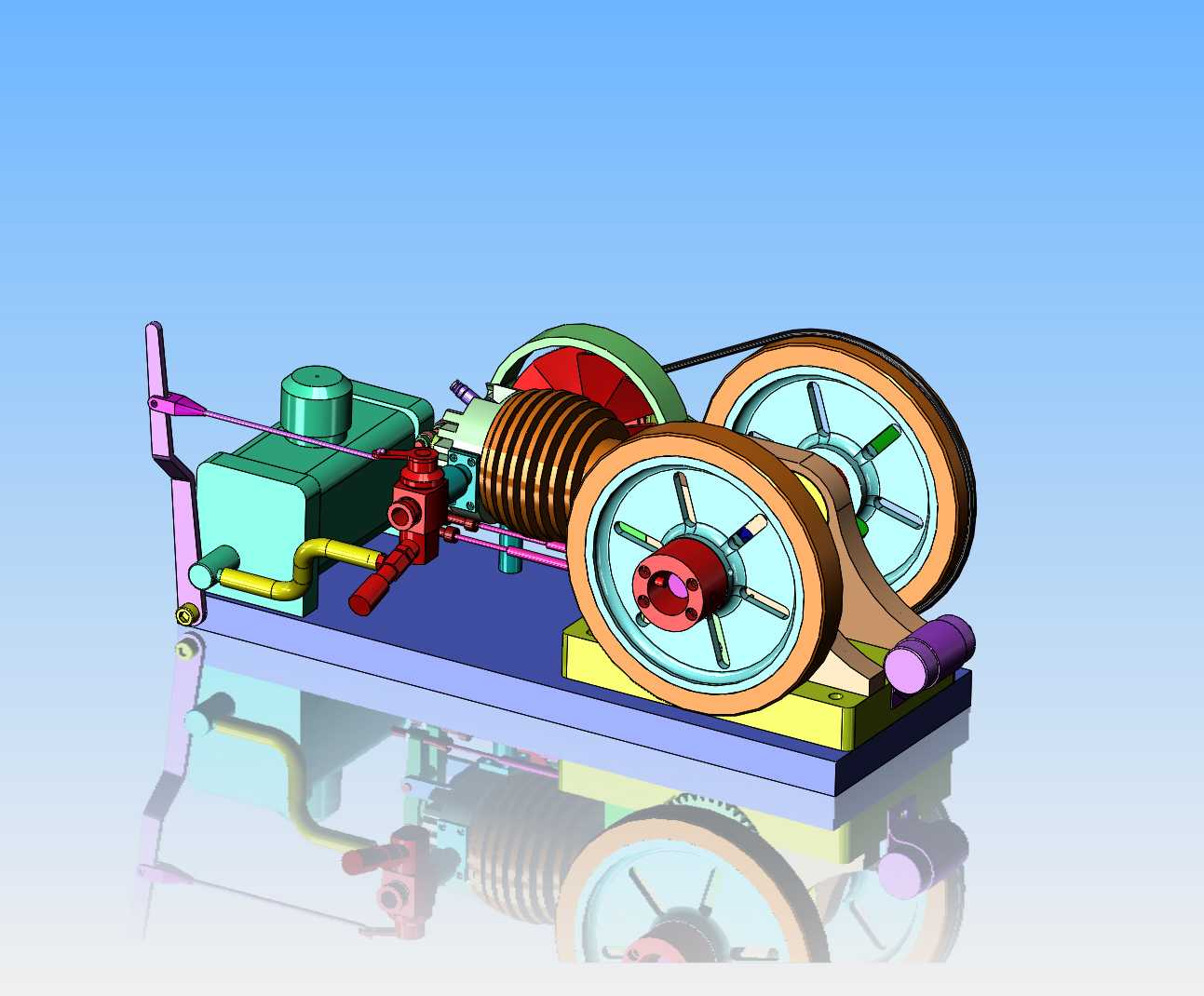

Horizontal Air Cooled Engine

- Thread starter Brian Rupnow

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

The engine just ran!!! God loves me after all. When all probable things have been tried, it is time to try the improbable. There was only one thing left to try that didn't involve machining something. I kept getting mixed signals about whether the sparkplug was really sealing against compression leakage or not.----So----Ten minutes ago I backed out the sparkplug, coated the threads with green 638 Loctite, then reinstalled the plug. Waited ten minutes and engine started up and ran like a trooper. I will get a video up tomorrow morning. I am so relieved.

638 is my "go-to" choice for Loctite. It is an excellent sealant, but releases very easily with a bit of torque. Like I said, all of my engines run---eventually. Some run right away and surprise me. Some require much thought and fiddling with. Out of about 20 engines, I haven't seen this happen before. I keep thinking that if I build enough of these small engines, I will get to the point where I can diagnose whatever is wrong and fix it immediately. The most difficult thing is knowing that everything is adjusted and set properly, and still the engine won't run. Thank you all for your suggestions and your interest.

Richard Hed

Well-Known Member

- Joined

- Nov 23, 2018

- Messages

- 2,381

- Reaction score

- 616

I am very surprized by that.638 is my "go-to" choice for Loctite. It is an excellent sealant, but releases very easily with a bit of torque. Like I said, all of my engines run---eventually. Some run right away and surprise me. Some require much thought and fiddling with. Out of about 20 engines, I haven't seen this happen before. I keep thinking that if I build enough of these small engines, I will get to the point where I can diagnose whatever is wrong and fix it immediately. The most difficult thing is knowing that everything is adjusted and set properly, and still the engine won't run. Thank you all for your suggestions and your interest.

The other 20 engines had commercial plugs with sealing washer, I raised the sealing issue as soon as I saw photos of the new plugs, Steve is not at fault as he just made them to the design he was sent.

Likewise 638 should not release easily but could be weakened by the heat of a hot cylinder head, it is really a retainer, for sealing and stopping threads coming lose use a studlock or thread sealant then less chance of stripping the head if you need to remove the plug

Likewise 638 should not release easily but could be weakened by the heat of a hot cylinder head, it is really a retainer, for sealing and stopping threads coming lose use a studlock or thread sealant then less chance of stripping the head if you need to remove the plug

Well done Brian, Obviously your accumulated experience got there in 10 minutes, where many of us would spend 10 days.... Is there a wway to fit a copper shim washer as a seal for the spark-plug? Many years ago, I had a motorcycle that had a "poor" seat fro the spark-plug to seal. I used copper washers - that were a thin-walled tube - which were very successful. But maybe a regular copper shim washer will suffice? (Or even a paper gasket washer?). I have used PTFE thread tape on many a gas connection that is otherwise "iffy". Takes cylinder head temperature as well.

Whatever works for you is fine.

K2

Whatever works for you is fine.

K2

The High tension Voltage goes up as the compression is raised and Likewise goes up when you increase the gap of the plug. You could try a couple of extra battery volts as well. Just make one change in the ignition at a time so you can Isolate what is causing the problem, but it has to be lack Of spark Cheers John.

- Joined

- Feb 17, 2008

- Messages

- 2,326

- Reaction score

- 440

Brian,

Is there any possibility that your fuel has become accidentally contaminated. I fiddled and fussed for a couple of hours trying to get a known runner started before discovering that I had been using some of last seasons fuel.

You might try running one of your known good runners with your fuel to make sure. Seems like you have tried most everything else at this point.

Gail

Is there any possibility that your fuel has become accidentally contaminated. I fiddled and fussed for a couple of hours trying to get a known runner started before discovering that I had been using some of last seasons fuel.

You might try running one of your known good runners with your fuel to make sure. Seems like you have tried most everything else at this point.

Gail

The fuel I used was new fuel. The battery is fully charged. There is nothing wrong with Steve Huck's sparkplugs. they work fine. I had Steve make two "special" plugs for me, and I knew there was very little shoulder on these plugs to snug down against the top of the cylinder. I didn't think they would leak around the plug threads, but I was wrong. We live, we learn.

So, here we are. The culmination of a two month thrash!!! I had a few problems sorting out a reliable head gasket, but solved that by going to a Viton o-ring head gasket instead of the treated cardboard that I have used on previous i.c. engines. I had major issues getting the engine to fire, but traced that back to leaking threads around the sparkplug. There was nothing wrong with the sparkplug, it was my funky threads in the cylinder head that were causing me grief. Once I got that sorted, the engine ran like a race-horse. These Traxxas carburetors have the touchiest throttle lever in the world. That throttle is intended to be operated by a servo, so is very touchy indeed. That is why during the video my finger doesn't leave the throttle lever--if I take my finger off the throttle the engine tries to run wide open and scares me half to death. I miss-spoke in the video and said the motor has a 1" stroke---that's not correct, it is actually 1 1/4" stroke. I will sell these plans (about 50 sheets) for $25 paid to my Paypal account. Contact me if you want to purchase a set of plans. Thank you for following my build on the forum.---Brian Rupnow

Conrats, Brian.

Going through the engine as you did - while we watched - reminds me of that Sherlock Holmes quote, "once you have eliminated all the rational causes, whatever remains must be considered, regardless of how improbable it may be." Eliminating the valves, the timing, the position of the spark gap and everything else left the compression leaks around the spark plugs.

(I've probably butchered the Sherlock Holmes quote - but it's like that).

Going through the engine as you did - while we watched - reminds me of that Sherlock Holmes quote, "once you have eliminated all the rational causes, whatever remains must be considered, regardless of how improbable it may be." Eliminating the valves, the timing, the position of the spark gap and everything else left the compression leaks around the spark plugs.

(I've probably butchered the Sherlock Holmes quote - but it's like that).

Bob-I was thinking of Sherlock when I wrote that.

Tomorrow I'll make up a "Casey Jones" throttle lever and linkage from it to the carburetor. A couple of Belleville washers between the throttle lever and the baseplate will add enough friction to keep the throttle from vibrating out of place.

Today, after some minor tweaking and tuning and the addition of a Casey Jones style throttle lever, the engine is running much more sedately. The folks who I generally buy Belleville washers from are temporarily out of stock, so even with the addition of my throttle lever the engine wants to "creep" to a higher rpm.--That gets scary as heck when the engine pulls the throttle wide open. My next trick will be to add the piston with cast iron rings and see how well it runs.---Brian

Hey Brian. Maybe try a throttle with a spring. Then you can rev when you want and it will return to idle when unattended. Also easy to adjust idle just by screwing the shaft in and out of the ball socket piece.

Thanks Steve---I didn't use a spring because I am going to use this engine to power something else. I like to have my throttle set up so I can advance it against a load and leave it advanced to keep the engine from slowing under load and stalling out.

- Joined

- Oct 1, 2010

- Messages

- 1,342

- Reaction score

- 395

Brian,

That's running beautifully now. From reading all your adventures with this engine, I take your "I'm Happy" as quite an understatement. We're all happy that you have arrived at a good place with this engine.

I like, the look, the sound, the finish, and the whole package you have made here.

--

Is there a chance you could make a "sandwich" of washers made of different materials to provide enough friction to prevent the throttle from creeping? I've been able to do that in the past, but not in anything so fiddly as your throttle.

--ShopShoe

That's running beautifully now. From reading all your adventures with this engine, I take your "I'm Happy" as quite an understatement. We're all happy that you have arrived at a good place with this engine.

I like, the look, the sound, the finish, and the whole package you have made here.

--

Is there a chance you could make a "sandwich" of washers made of different materials to provide enough friction to prevent the throttle from creeping? I've been able to do that in the past, but not in anything so fiddly as your throttle.

--ShopShoe

Hi Shopshoe---Happy New Year--I have some Belleville washers on order, they will be here this week or next. The trouble with stacking washers is that the pivot bolt at the bottom of the throttle arm will unscrew if you leave it free enough to move by hand. If you tighten the screw so it doesn't vibrate out of position, then it is too stiff to operate with your fingers.---Brian

It appears that the carburetor throttle has a square to locate the arm, why not rotate the arm 90° and place your Casey Jones style throttle lever 90° to the engine cylinder, I suspect the vibration of the running engine is parallel to the cylinder which is why the level moves in the first place.Hi Shopshoe---Happy New Year--I have some Belleville washers on order, they will be here this week or next. The trouble with stacking washers is that the pivot bolt at the bottom of the throttle arm will unscrew if you leave it free enough to move by hand. If you tighten the screw so it doesn't vibrate out of position, then it is too stiff to operate with your fingers.---Brian

Similar threads

- Replies

- 11

- Views

- 2K

- Replies

- 25

- Views

- 3K