Tony, Rob and Kevin,

Thanks :bow: glad you enjoyed my rambling. That's one of the fun things about being here, it jogs the memory. Whilst some of these are very funny, we are all very lucky they are not the other half of the comedy/tragedy equation.

Have you ever had one of those days ??? Well today was my turn.

On dismantling the face plate and rotary table, I noticed the table had developed a bit more backlash than I like. Thinks........ I'll fix it now,.......only take five minutes. On removing the handwheel, I dropped the drive key. Heard a ting as it hit the floor and that was that.

After a hour of fruitless searching, my blood pressure way exceeded most boilers test pressure, steam was coming from my ears and the air was blue. This did little to improve my eyesight and the key remains lost. After tea and a fag I decided I would make a new one.......only take five minutes......correct until you drop that one and can't find it either.

Key #3 was duly fashioned and the handwheel replaced.

Enough excitement for one day, having achieved a working RT with minimal backlash, it was time to quit whilst I was ahead.

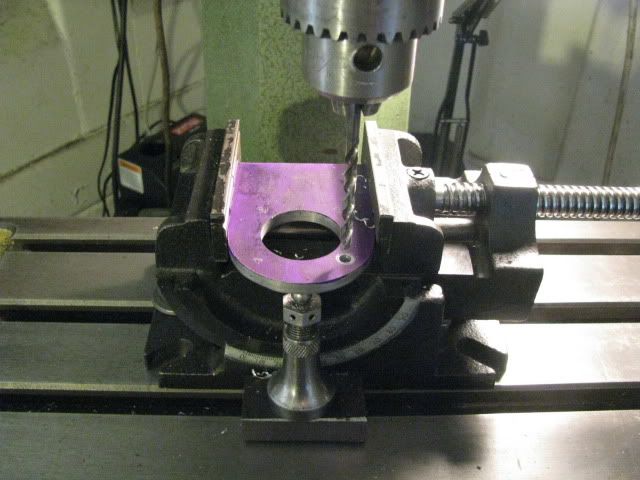

Consolation prize.

Bigger burner for my LPG torch.

Have a great weekend.

Best Regards

Bob