Maryak

Well-Known Member

- Joined

- Sep 12, 2008

- Messages

- 4,990

- Reaction score

- 77

Jeff and Philly,

Hand filing is an art, I had 2 problems, our instructor was a complete and utter arthole and I'm no artist.

The Engineer,

Thanks for your support and inside info on this engine. :bow:

Today's progress report.

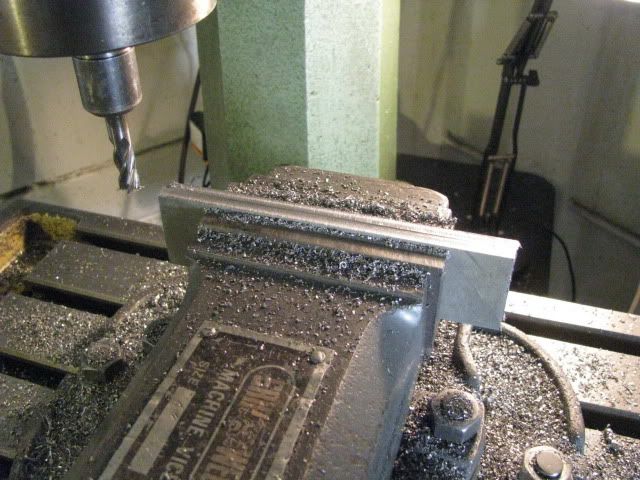

Setup to mill the relevant flat bits.

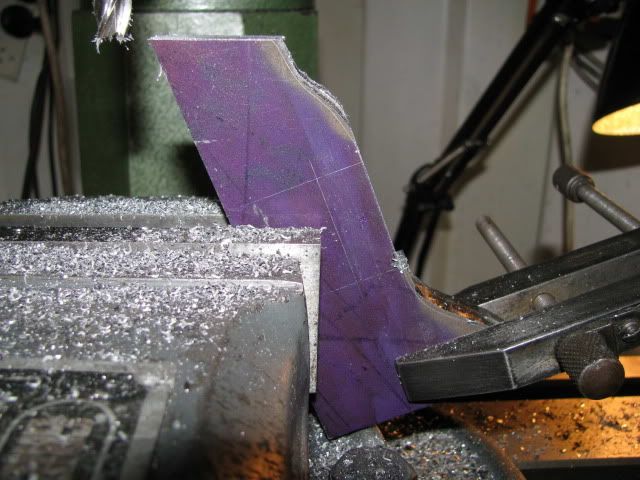

Filing the 1st compound curve - for those who are new to filing - a good finish is achieved by using a smooth file, with the teeth filled with blackboard chalk. Usually the smaller the file the smaller the teeth. In my files I go from 10" to 4" in 3 cuts, bastard, second cut and smooth. In this case the finish was with a 6" half round smooth file. The file must be free of any metal trapped in the teeth, (remove them with an old scriber point), It must also be cleaned regularly using a file card, ( a flat say, 1 1/2" x 4" wire brush with the bristles finely spaced, about 1/4" high). Lastly the final filing is done using draw filing, i.e. the file is held parallel to the body with a hand on each side and drawn back and forth on the work.

The 1st compound curve completed.

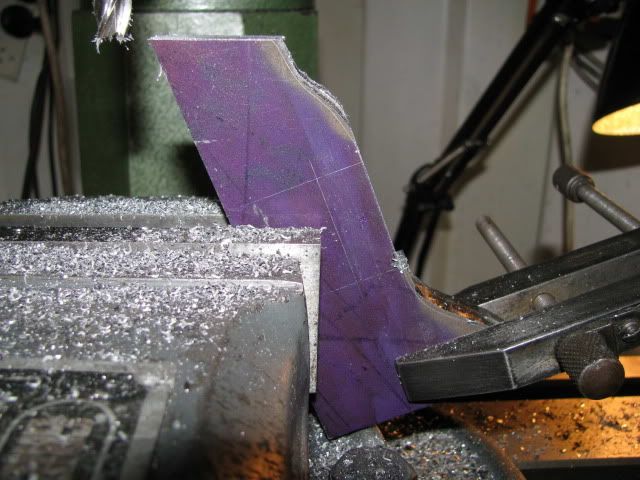

The 2nd compound curve completed.

Base piece 2 - 2off.

Have a great day.

Best Regards

bob

Hand filing is an art, I had 2 problems, our instructor was a complete and utter arthole and I'm no artist.

The Engineer,

Thanks for your support and inside info on this engine. :bow:

Today's progress report.

Setup to mill the relevant flat bits.

Filing the 1st compound curve - for those who are new to filing - a good finish is achieved by using a smooth file, with the teeth filled with blackboard chalk. Usually the smaller the file the smaller the teeth. In my files I go from 10" to 4" in 3 cuts, bastard, second cut and smooth. In this case the finish was with a 6" half round smooth file. The file must be free of any metal trapped in the teeth, (remove them with an old scriber point), It must also be cleaned regularly using a file card, ( a flat say, 1 1/2" x 4" wire brush with the bristles finely spaced, about 1/4" high). Lastly the final filing is done using draw filing, i.e. the file is held parallel to the body with a hand on each side and drawn back and forth on the work.

The 1st compound curve completed.

The 2nd compound curve completed.

Base piece 2 - 2off.

Have a great day.

Best Regards

bob