Maryak

Well-Known Member

- Joined

- Sep 12, 2008

- Messages

- 4,990

- Reaction score

- 77

Rob,

Thanks for the kind words and support.

Well, we almost have a firm base on which to sally forth. :

:

Base piece 6 completed.

The base welded together - (My angle grinder is at home for honey dos so you have to suffer a look at my welds.

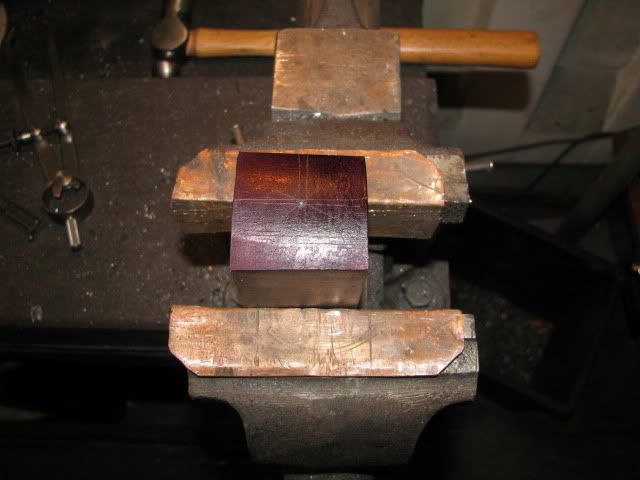

Squaring up after welding.

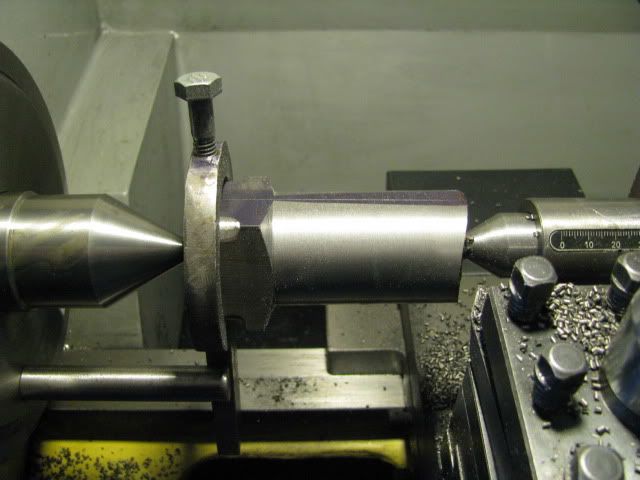

Machining the bearing housing cut aways.

That's All Folks.

Best Regards

Bob

Thanks for the kind words and support.

Well, we almost have a firm base on which to sally forth.

Base piece 6 completed.

The base welded together - (My angle grinder is at home for honey dos so you have to suffer a look at my welds.

Squaring up after welding.

Machining the bearing housing cut aways.

That's All Folks.

Best Regards

Bob