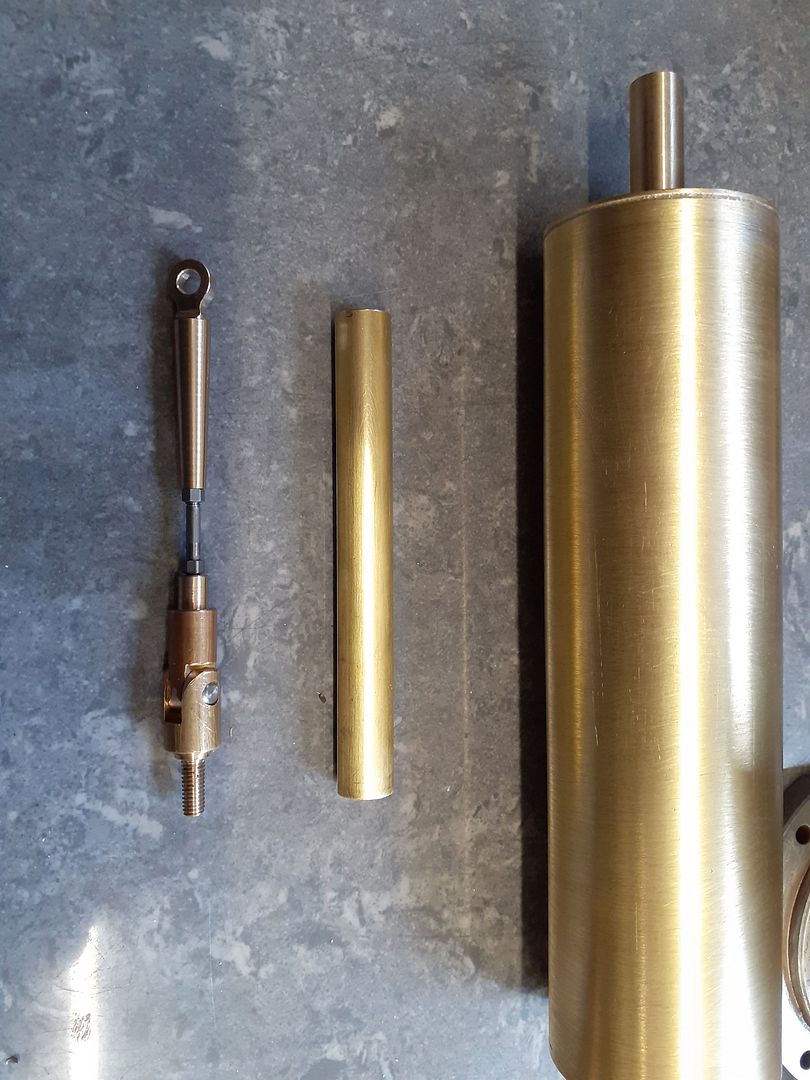

This is my latest effort a Heinrici hot air engine based on drawings intended for making with castings but I altered them to suit my usual fabrication and cutting from solid methods as well as a few other details taken from original engines. I decided to do something a bit different with teh paintwork too.