vascon2196

Well-Known Member

- Joined

- Oct 2, 2009

- Messages

- 1,026

- Reaction score

- 312

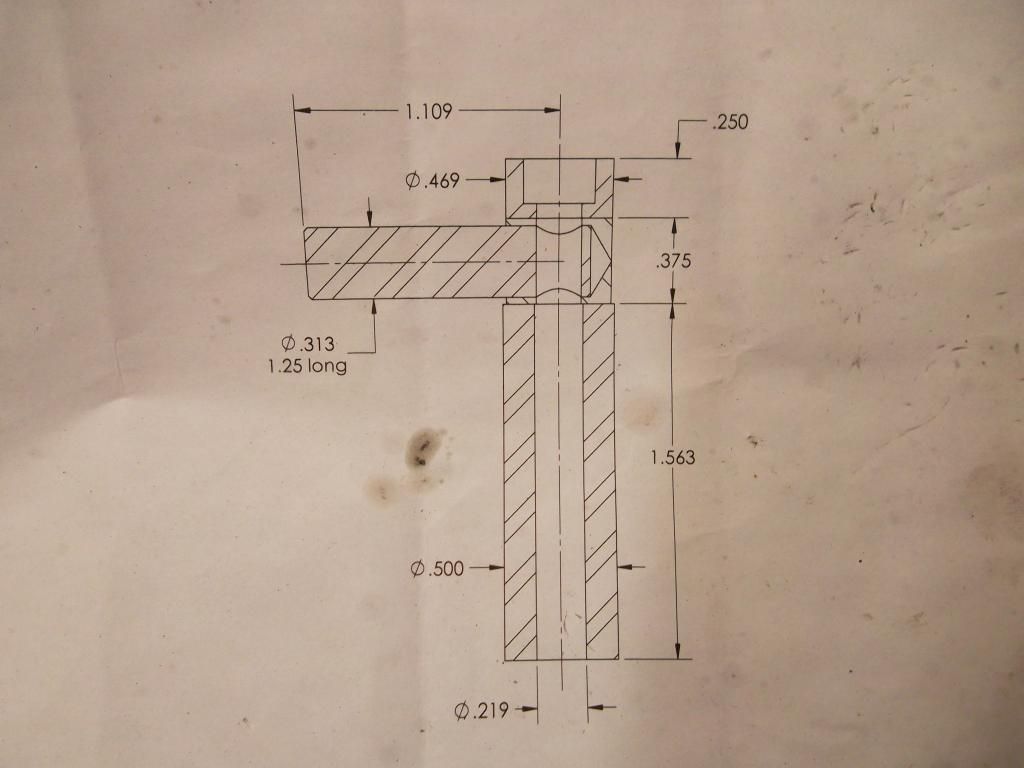

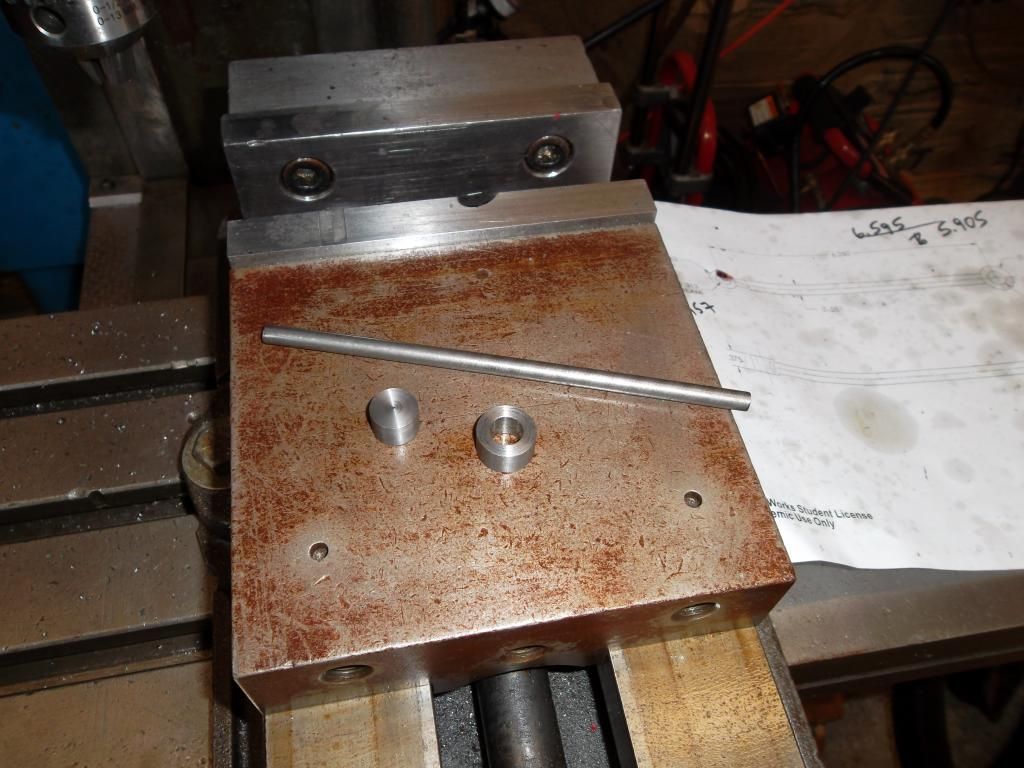

Thanks again folks...can't wait to continue working on this. I have been updating the drawings as I go. Hopefully I will have a nice clean set of prints when this is all over to share.

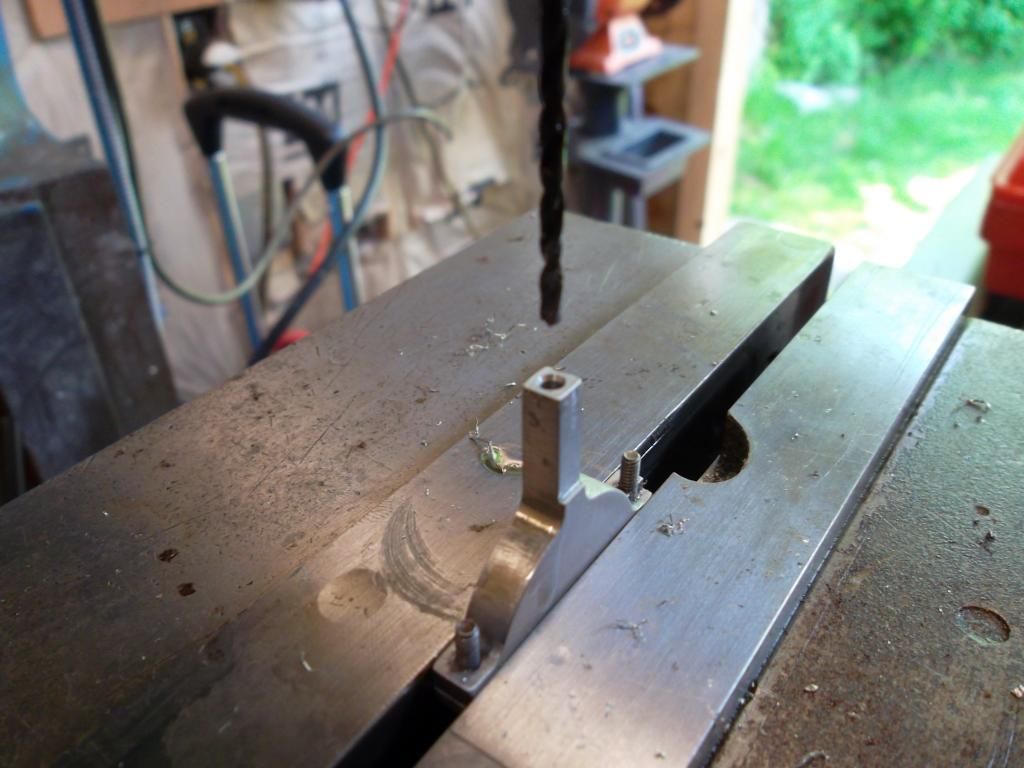

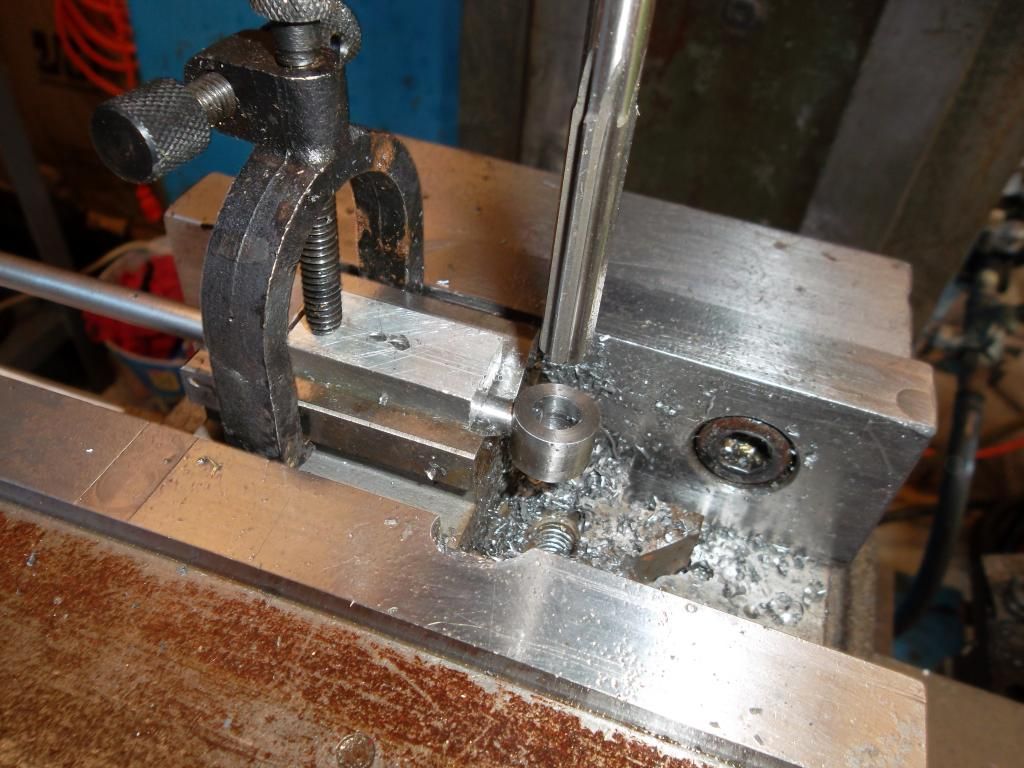

I ended up tapping the #5-40 mounting holes but skipped the pictures...it was not very exciting. If I broke a tap, then you would have got some pictures and a few curse words!

I ended up tapping the #5-40 mounting holes but skipped the pictures...it was not very exciting. If I broke a tap, then you would have got some pictures and a few curse words!