vascon2196

Well-Known Member

- Joined

- Oct 2, 2009

- Messages

- 1,026

- Reaction score

- 312

Well here goes...while in the midst of building a full-scale Ford Quadricycle I have decided to move forward with a half-scale version of just the engine. I'm not sure which project will be completed first but since I am in no rush...it doesn't matter! I'm not finished with the half-scale plans yet because I stopped at the intake and exhaust valves...I'm hoping those will evolve during the engine build and I will document the progress along the way.

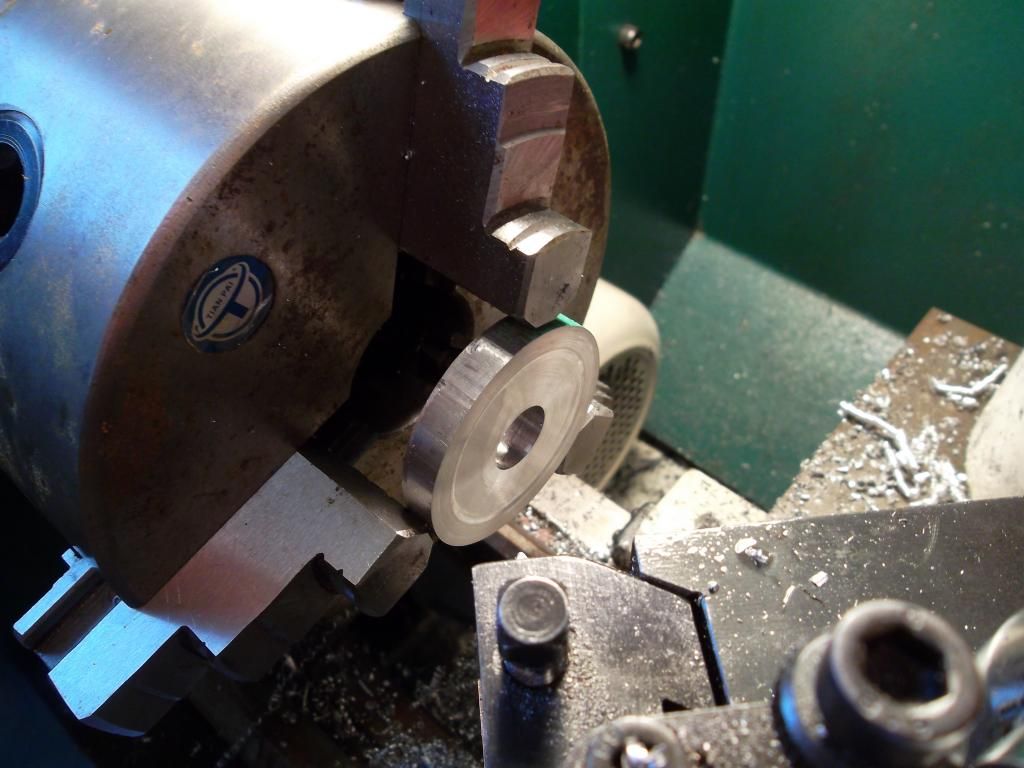

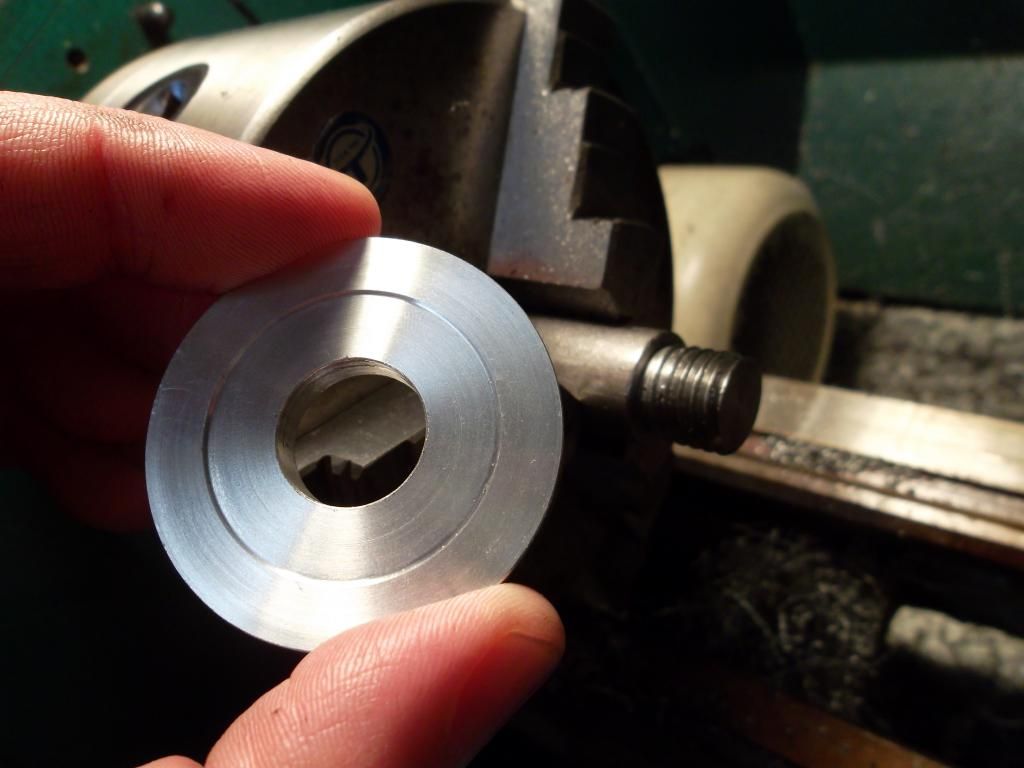

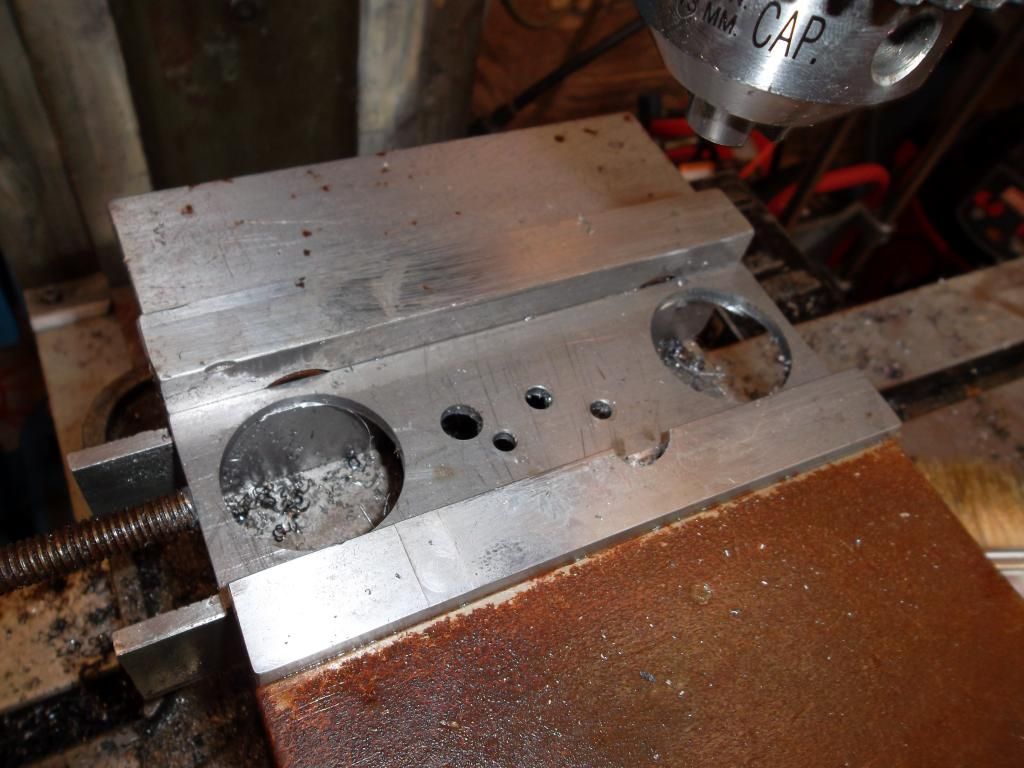

I decided to start with the "main bearings". Originally Ford made them out of cast Bronze (he made the pattern for them also), but I am machining them both from rectangular aluminum bar stock as shown in the pictures.

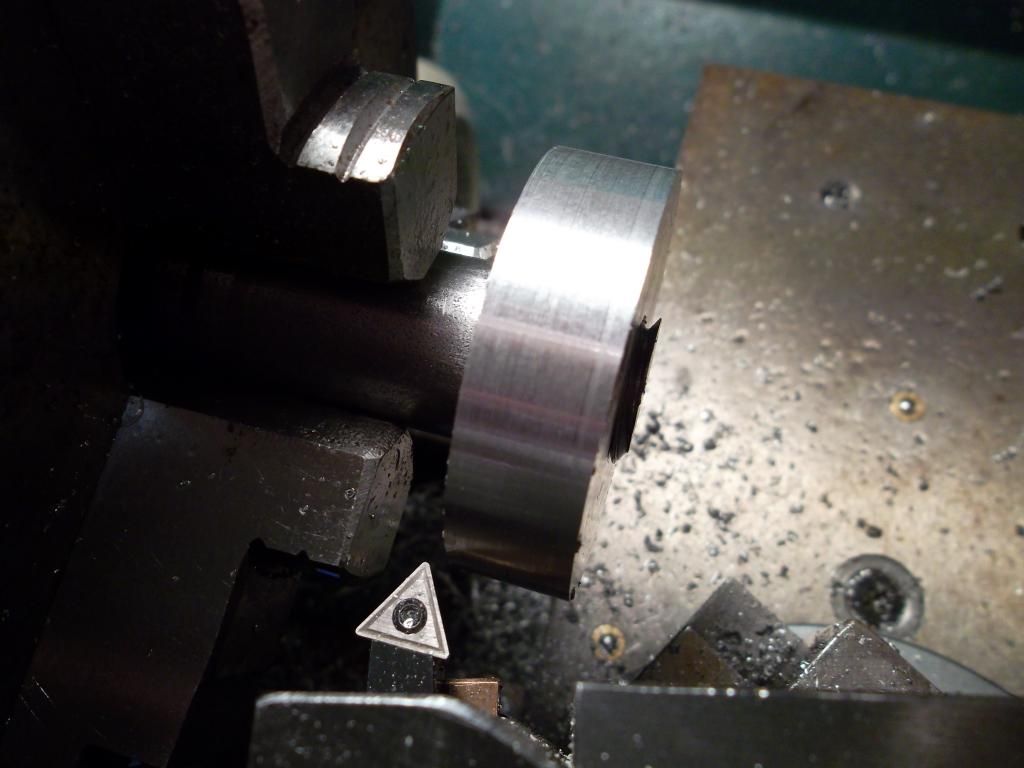

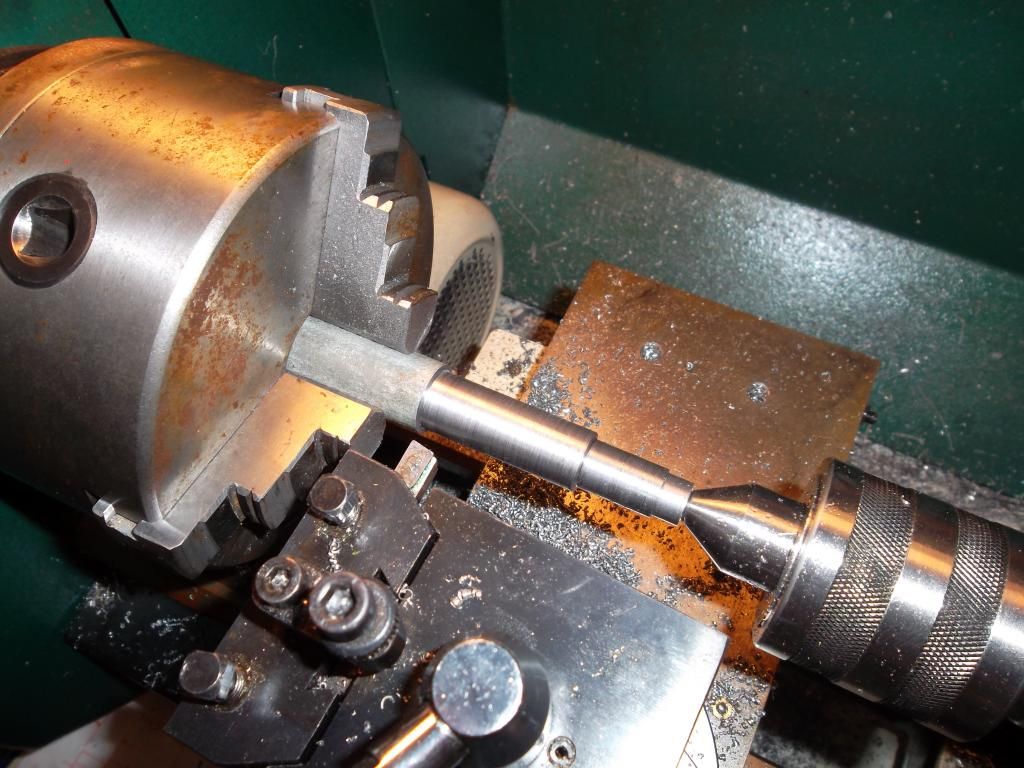

I had to make a custom boring tool that did not give me the nicest internal surface finish but those surfaces will be facing the cylinders so nobody will ever see them. My next step is to saw cut the part in half and then mill to the final thickness...resulting in two parts.

Then I plan on adding the mounting holes.

Much, much, much, more to come...hope you enjoy!

I decided to start with the "main bearings". Originally Ford made them out of cast Bronze (he made the pattern for them also), but I am machining them both from rectangular aluminum bar stock as shown in the pictures.

I had to make a custom boring tool that did not give me the nicest internal surface finish but those surfaces will be facing the cylinders so nobody will ever see them. My next step is to saw cut the part in half and then mill to the final thickness...resulting in two parts.

Then I plan on adding the mounting holes.

Much, much, much, more to come...hope you enjoy!