I've got some sealing issues around the engine steam lines on mine as well-- some paper gasket material and sealer helps, but I think there's just too many sliding bits to really be a good joint. The easy answer might be soft soldering and just desoldering it for disassmbly, but I don't like that much and think if I were to do it again I'd try making a small compression fitting. Kozo's New Shay book has some instructions on making compression fittings in the back that look fairly simple to fab.

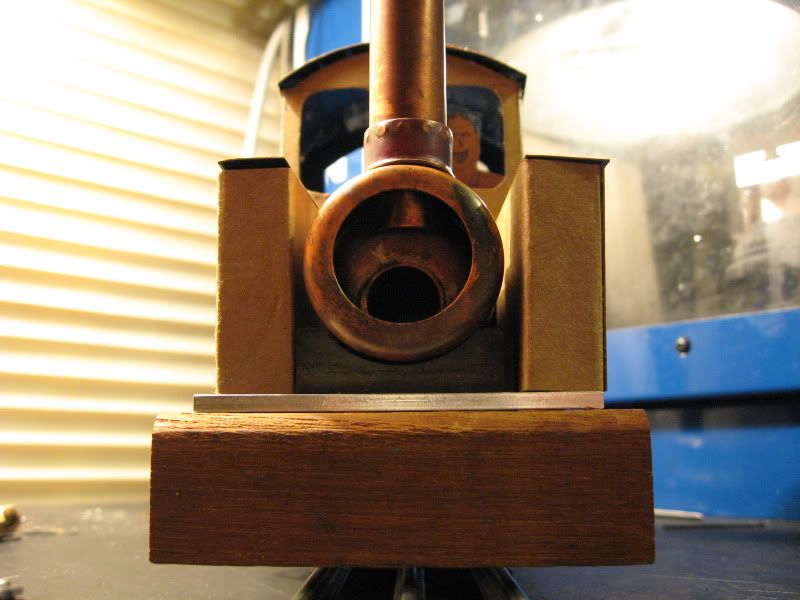

Btw, the exhaust on mine is kind of a trick-- there's no sealing needed and the 'drilled bolt' is long enough internally that it can be unscrewed and slid up the pipe to the smokebox far enough to clear the threads and remove that pipe without pulling any of the other engine bits.

Btw, the exhaust on mine is kind of a trick-- there's no sealing needed and the 'drilled bolt' is long enough internally that it can be unscrewed and slid up the pipe to the smokebox far enough to clear the threads and remove that pipe without pulling any of the other engine bits.