You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Elmer's Tiny

- Thread starter PhiberOptix

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

PhiberOptix

Well-Known Member

- Joined

- Jul 29, 2009

- Messages

- 146

- Reaction score

- 1

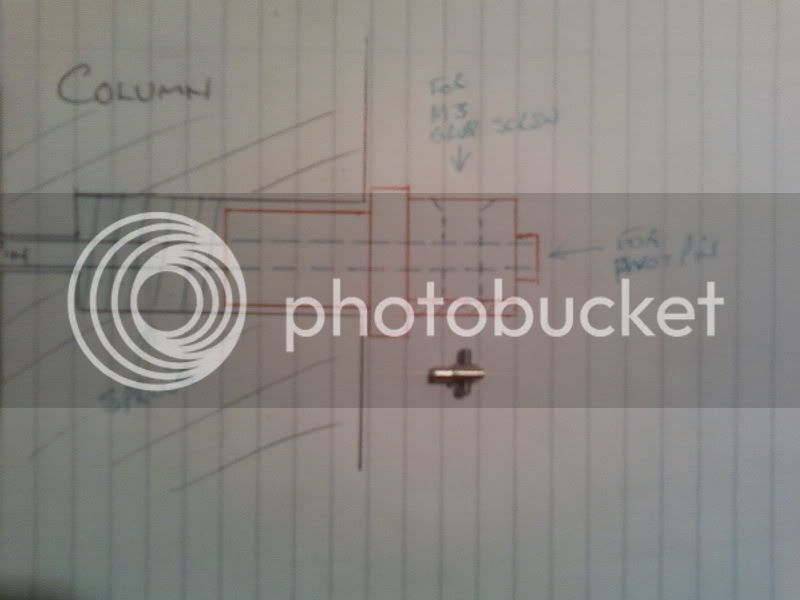

Minor problems

I am struggling to find a spring for the pivot pin

I struggled to find a strong enough magnifying glass to let me see the pivot pin to drill it

decided to make a modification rather than attempting to drill

quite simply this is a sleeve that goes over the pivot pin with with a shoulder for the spring to push against

and an M3 grub screw to nip on to the pivot pin and a flat filed on the bottom to give clearance for the fly wheel

problem solved (the red hashed area is the area i filed away)

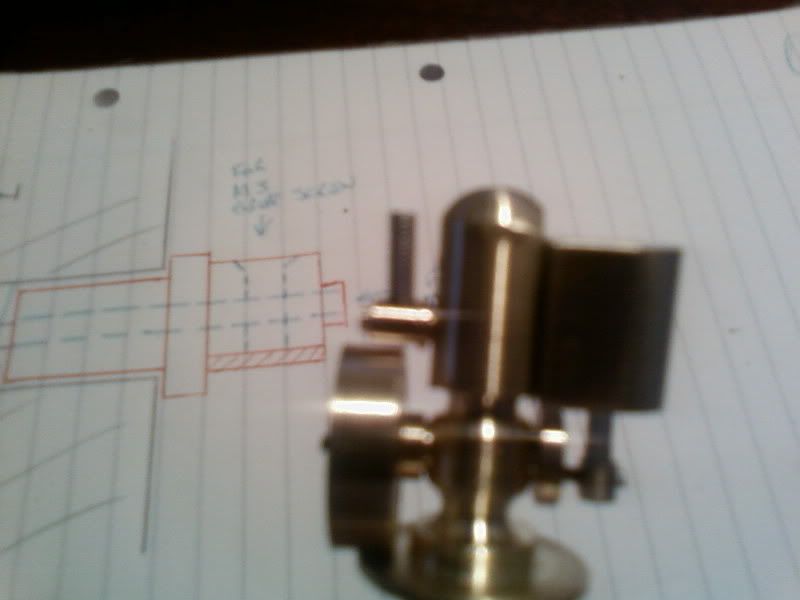

here the sleeve is fitted in situ, however a shorter M3 grub screw is needed

I will take the engine to my friends workshop to use his compressor & regulator tomorrow

they wasn't open today been sunday sorry.

I am struggling to find a spring for the pivot pin

I struggled to find a strong enough magnifying glass to let me see the pivot pin to drill it

decided to make a modification rather than attempting to drill

quite simply this is a sleeve that goes over the pivot pin with with a shoulder for the spring to push against

and an M3 grub screw to nip on to the pivot pin and a flat filed on the bottom to give clearance for the fly wheel

problem solved (the red hashed area is the area i filed away)

here the sleeve is fitted in situ, however a shorter M3 grub screw is needed

I will take the engine to my friends workshop to use his compressor & regulator tomorrow

they wasn't open today been sunday sorry.

PhiberOptix said:decided to make a modification rather than attempting to drill

Must Admit Andy, having read you were intending drilling through a 1/16" wire I wasn't envying you the task, ............ though I was looking forward to learning how to do it .............

Nice work around though mate 8)

CC

arnoldb

Well-Known Member

- Joined

- Apr 8, 2009

- Messages

- 1,792

- Reaction score

- 12

Phiber, nice solution. However, won't that configuration compress the spring too much? - maybe shorten the part entering the column a bit.

You might find a spring from a ball-point pen - try some "cheapy" click-pens with thin-diameter refills to see if you can find one.... Think BIC

If I may offer a suggestion... - For my Fancy's flywheel, I needed a shorter 3mm grub screw as well; I just stack the grub screw on it's correct size allenkey to give something to hold onto, and ground it down with the bench grinder. A full tin-can of water helps to cool it down every once in a while; if the can is not full, it is difficult to keep the grub screw on the allenkey when cooling.

Regards, Arnold

You might find a spring from a ball-point pen - try some "cheapy" click-pens with thin-diameter refills to see if you can find one.... Think BIC

If I may offer a suggestion... - For my Fancy's flywheel, I needed a shorter 3mm grub screw as well; I just stack the grub screw on it's correct size allenkey to give something to hold onto, and ground it down with the bench grinder. A full tin-can of water helps to cool it down every once in a while; if the can is not full, it is difficult to keep the grub screw on the allenkey when cooling.

Regards, Arnold

PhiberOptix

Well-Known Member

- Joined

- Jul 29, 2009

- Messages

- 146

- Reaction score

- 1

arnoldb said:Phiber, nice solution. However, won't that configuration compress the spring too much? - maybe shorten the part entering the column a bit.

You might find a spring from a ball-point pen - try some "cheapy" click-pens with thin-diameter refills to see if you can find one.... Think BIC

If I may offer a suggestion... - For my Fancy's flywheel, I needed a shorter 3mm grub screw as well; I just stack the grub screw on it's correct size allenkey to give something to hold onto, and ground it down with the bench grinder. A full tin-can of water helps to cool it down every once in a while; if the can is not full, it is difficult to keep the grub screw on the allenkey when cooling.

Regards, Arnold

Thank you Arnold,

I am afraid it is going be a bit of a trial and error phase tomorrow, between shortening the sleeve as you so rightly suggested and/or shortening the spring and/or deepening the springs hole in the column,

I have already been looking at pen springs and the springs in lighters that push the flint against the 'flick' wheel, so far either too small or too large, I am still on the hunt, and if you look back to the wire hunt, I dint give up easily

As for the M3 grub screws, I know my m8 has some at his Workshop

Regards

Andy

PhiberOptix

Well-Known Member

- Joined

- Jul 29, 2009

- Messages

- 146

- Reaction score

- 1

Managed to find a whole host of springs Only 1 fitted!!!!!

and after trimming one down we are ready for tomorrow

Ooh the $1 Coin is for 'Zee'

The spring is the speck under the penny above the modification

and after trimming one down we are ready for tomorrow

Ooh the $1 Coin is for 'Zee'

The spring is the speck under the penny above the modification

zeeprogrammer

Well-Known Member

- Joined

- Mar 14, 2009

- Messages

- 3,362

- Reaction score

- 13

Amazing that an engine can fit inside a coin.

Sorry to be a bit off topic...but you brought back a memory.

Wife and I were married in 75. Someone gave us 5 spankin' new Eisenhower dollar coins as a present. I have three left. One day...shortly after we were married...well we were hungry...

You can bet many are looking forward to tomorrow.

Sorry to be a bit off topic...but you brought back a memory.

Wife and I were married in 75. Someone gave us 5 spankin' new Eisenhower dollar coins as a present. I have three left. One day...shortly after we were married...well we were hungry...

You can bet many are looking forward to tomorrow.

zeeprogrammer said:Wife and I were married in 75.

"74" for us, however, as far as I recall we haven't eaten any wedding presents ........... yet ............. :

Good luck for the next 34

CC

- Joined

- Dec 28, 2008

- Messages

- 548

- Reaction score

- 4

Andy,

Based on how fast you banged this together, you have the skills to drill the cross hole. Thm: Just do it. That's the fun part of the hobby; overcoming the stuff that you think is hard to do. The satisfaction that you will get when you successfully drill that hole is worth it. woohoo1

Bob

Based on how fast you banged this together, you have the skills to drill the cross hole. Thm: Just do it. That's the fun part of the hobby; overcoming the stuff that you think is hard to do. The satisfaction that you will get when you successfully drill that hole is worth it. woohoo1

Bob

Yeah, that cross hole kind of comes as a surprise in the plans. I posted a simple jig to do it way back when. I'll see if I can find the link.

Update: here it is. I think that picture got blurrier with time http://www.homemodelenginemachinist.com/index.php?topic=627.msg3984#msg3984

http://www.homemodelenginemachinist.com/index.php?topic=627.msg3984#msg3984

One more place to find tiny springs is inside tire valves.

Update: here it is. I think that picture got blurrier with time

One more place to find tiny springs is inside tire valves.

PhiberOptix

Well-Known Member

- Joined

- Jul 29, 2009

- Messages

- 146

- Reaction score

- 1

90LX_Notch said:Andy,

Based on how fast you banged this together, you have the skills to drill the cross hole. Thm: Just do it.

Bob

shred said:I posted a simple jig to do it way back when.

OK Bob just for you

Thank you Bob and Shred for the encouragement and the Jig idea

I went around to my friends workshop to try the engine out on his air line, unfortunatly, he had a client there so will try again tomorrow if i get a chance, but its looking good when i flick the the fly wheel the crank turns quite freely lifting the piston up and down and rocking the cylinder to and fro, I can see no daylight inbetween the cylinder and column, so I am sure it will run, however, the suspense of waiting to see her go is killing me.

- Joined

- Jan 3, 2008

- Messages

- 2,085

- Reaction score

- 17

I just noticed the rounded "dome" of the body...I like that !! Sorry the run got cut short but still looking forward to the video and I'm sure the run will be a great success

Bill

Bill

zeeprogrammer

Well-Known Member

- Joined

- Mar 14, 2009

- Messages

- 3,362

- Reaction score

- 13

Very nice work Andy.

Post again with a scale (or coin ;D).

The finished engine will impress more. I mean it already impresses..but the coin...you know...ahhh

Post again with a scale (or coin ;D).

The finished engine will impress more. I mean it already impresses..but the coin...you know...ahhh

PhiberOptix

Well-Known Member

- Joined

- Jul 29, 2009

- Messages

- 146

- Reaction score

- 1

zeeprogrammer said:Very nice work Andy.

Post again with a scale (or coin ;D).

The finished engine will impress more. I mean it already impresses..but the coin...you know...ahhh

'Zee' - Mission Accepted

zeeprogrammer

Well-Known Member

- Joined

- Mar 14, 2009

- Messages

- 3,362

- Reaction score

- 13

I was right! 'Very' impressive.

Great job and thanks for the thread.

Great job and thanks for the thread.

- Joined

- Dec 28, 2008

- Messages

- 548

- Reaction score

- 4

Andy,

Great job! Didn't you feel good after drilling the hole? Victory is greater when you over come obstacles / challenges.

Are you going to go for the 1/2 scale next?

Bob

Great job! Didn't you feel good after drilling the hole? Victory is greater when you over come obstacles / challenges.

Are you going to go for the 1/2 scale next?

Bob

PhiberOptix

Well-Known Member

- Joined

- Jul 29, 2009

- Messages

- 146

- Reaction score

- 1

90LX_Notch said:Great job! Didn't you feel good after drilling the hole?

Are you going to go for the 1/2 scale next?

Did I feel good NO but I did feel an overwhelming sense of relief ;P Then I started to feel extremley good

I just couldn't see the forest for the trees, why I never thought of a jig in the first instance Ill never know, easy in hind sight lol, Jigs seem to spring to mind when I have multiples of items to do.

as for 1/2 scale.... that will be erm a NO.... I was thinking of going the other way DOUBLE size ROFLMAO

well maybe in the future I will try a 1/2 scale but first I need to get some sort of microscope headset/glasses, as my diabetes is way out of line it has drastically affected my eye sight, hopefully this will return back to normal as my glucose levels do

I am fitting some digital slides to my machine tomorrow, then I will be looking for my next project, at this moment I have not got a clue what to do next, probably a QCTP still looking for plans for a cam locking mechanism.

I have been looking at a 'Fancy' tho this seems very similar in concept to the tiny, I also like to look of 'Standby'

I had seen plans for a variation off this using a piece of tube as the piston, sideways in square cylinder, I really do like that idea.

I would like to thank you Bob for pointing me in the right direction as when I wanted to do 'Elmer's Tiny' after seeing it on your profile picture, I did not even know what it was called, So a big big thank you to you.

I would also like to thank Arnold as I think it was his 'Rocker' that I saw in a thread that re kindled the desire to build some engines.

I would also like to thank everyone else who commented in this thread, offered advice and encouragement

Similar threads

- Replies

- 0

- Views

- 213

- Replies

- 2

- Views

- 837

- Replies

- 57

- Views

- 9K