A little more progress over the last couple of days. First though, a question. I have been posting text and then the images that relate to that text as that is the only way I can see to do it. Yet in other posts I see text and images intermingled. I would much prefer to embed my images but don't know how. Can anyone offer up a few tips? Thanks.

So, I went to a local machinists group meeting last weekend and took along a few of my bits and pieces. They were all very polite and seemed to be interested in what I was doing, without even scorning my table top machines. Anyway, at that meeting I realized that despite the near perfect fit between the cylinder heads and my bore, I would have to set them aside and make new ones. Why?, well I made them to fit a cylinder that was a few thou under target and wasn't finished. Yes, I know I could have used them and just let the engine settle in on its own, but the bore was tapered very slightly and I wanted a better finish before I ran it. Not enough spring cuts, I guess.

Cover your eyes now if you are squeemish. Not having any laps available, I decided a reamed bore would have to do. I loaded up the cylinder and .500 reamer with cutting oil and ran it through. That all worked out reasonably well but I now had two heads that no longer fit like I wanted. The outer end was no issue, but the inner end with the packing for the piston rod could be tough to locate accurately. Besides, I plan on painting this engine, and thought brass heads might look nice against the paint. The aluminum heads will get saved for something else I can finish out nicely slightly undersize.

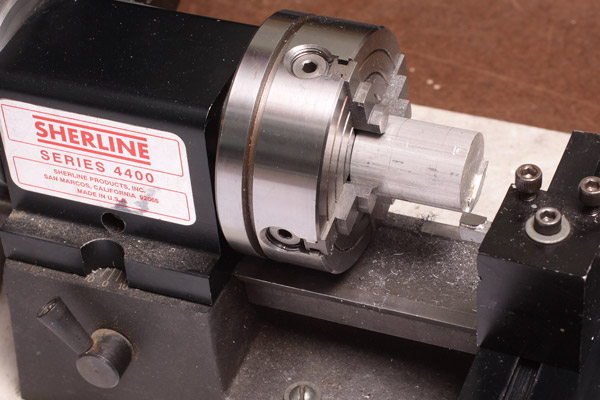

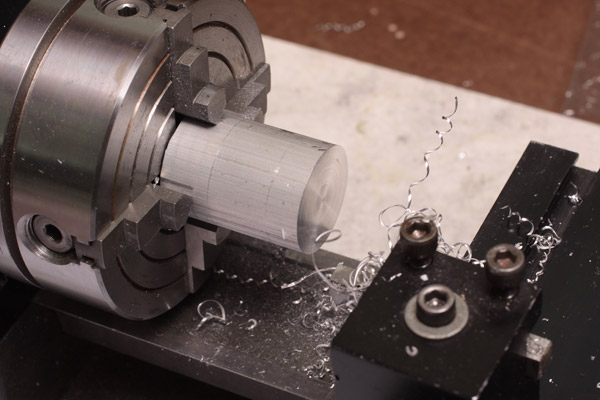

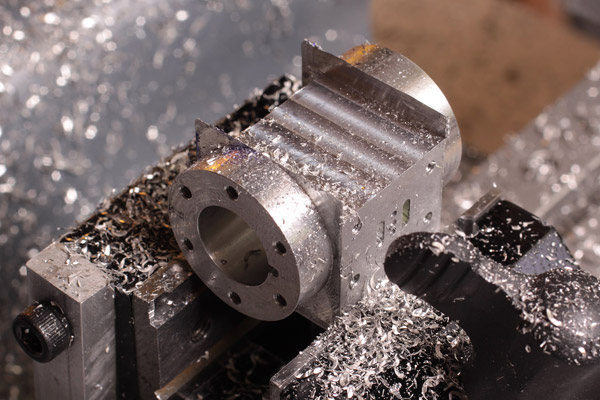

And now, back to the lathe. I didn't have any 1-inch brass stock so had to throw away a lot of some 1-1/4 that I have. It pained the cheap Scot in me - I was throwing away 58% of the material before I even got started after all. Working through my steps before cutting the blank I realized that the split bush meant I no longer needed a spigot for holding and I could use less than 3/4 of an inch of stock if I was careful, including the initial saw kerf.

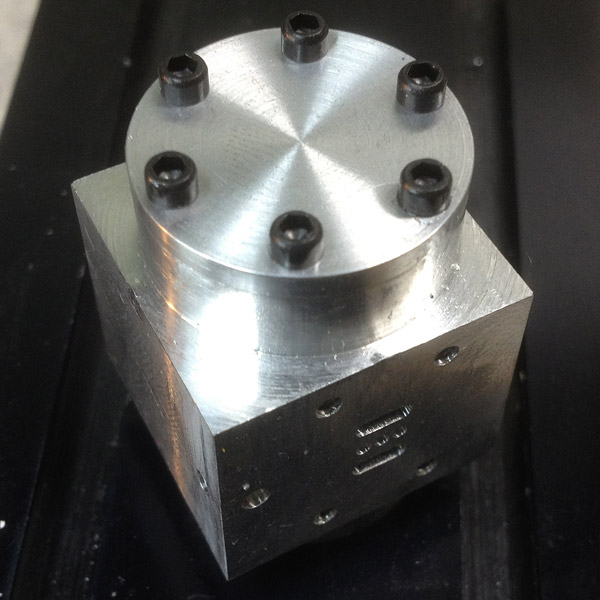

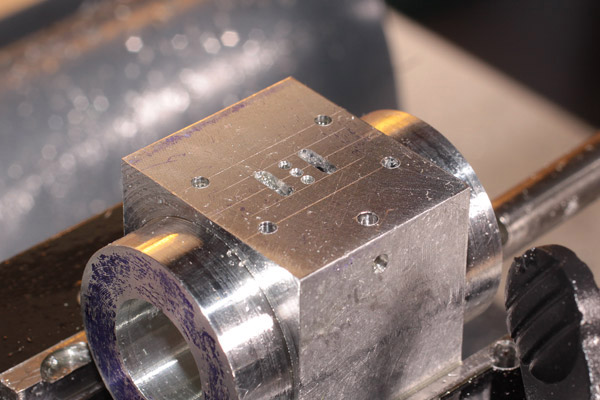

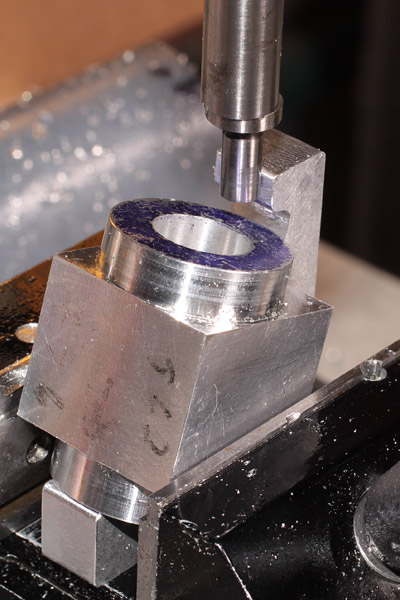

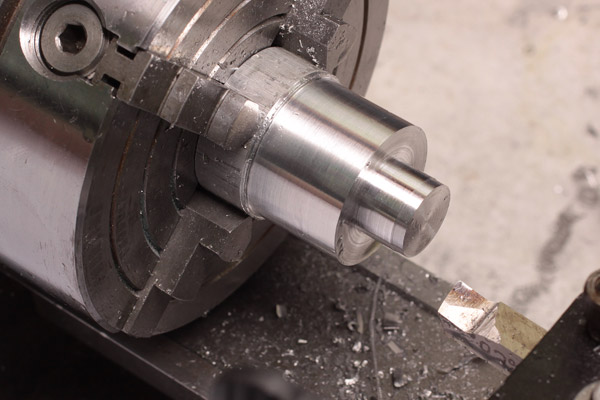

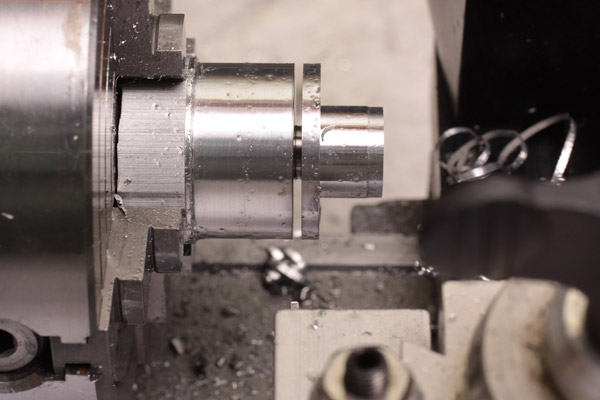

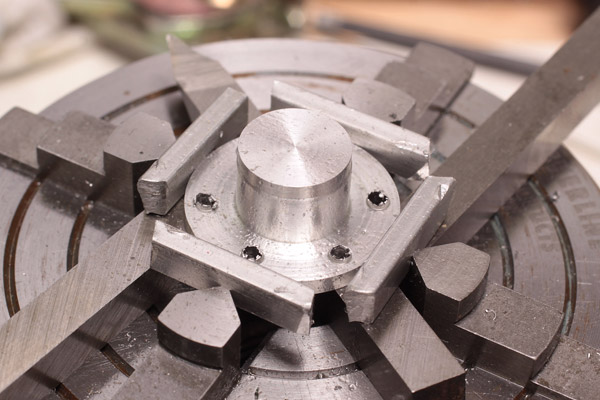

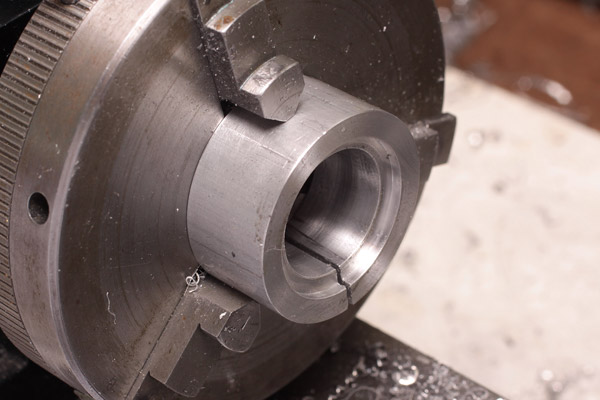

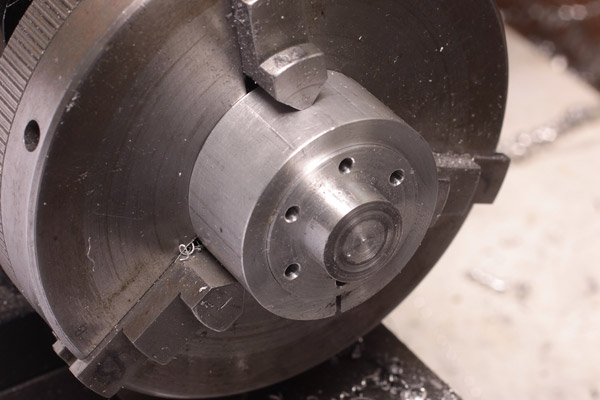

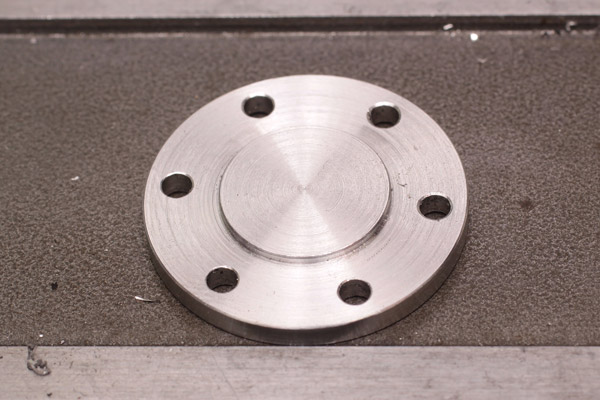

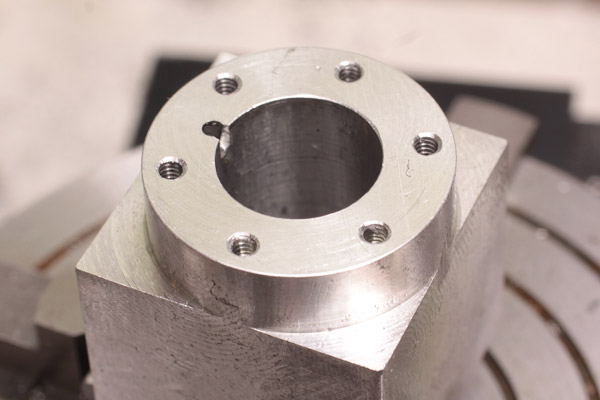

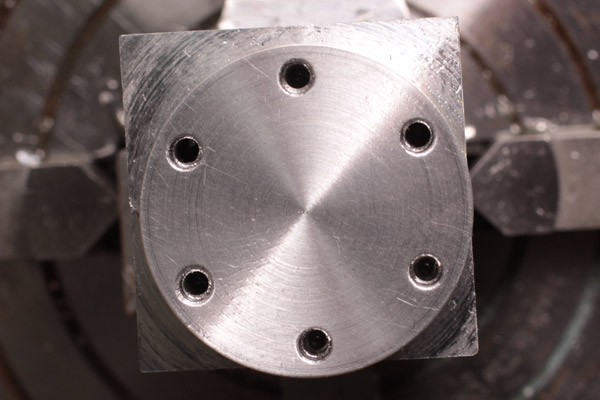

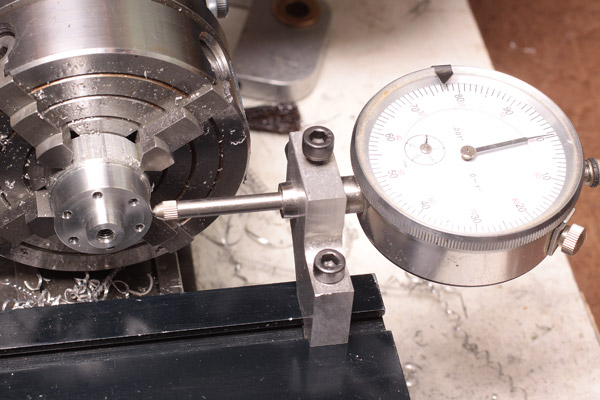

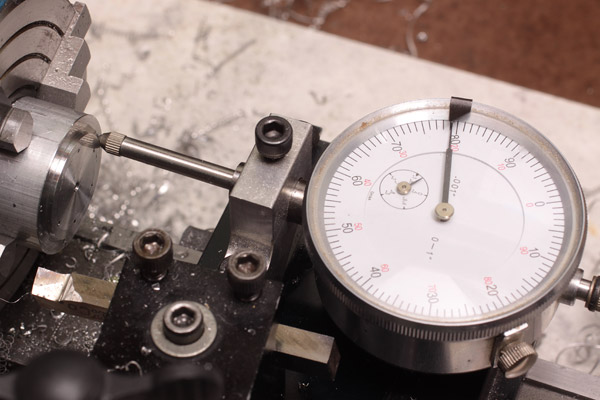

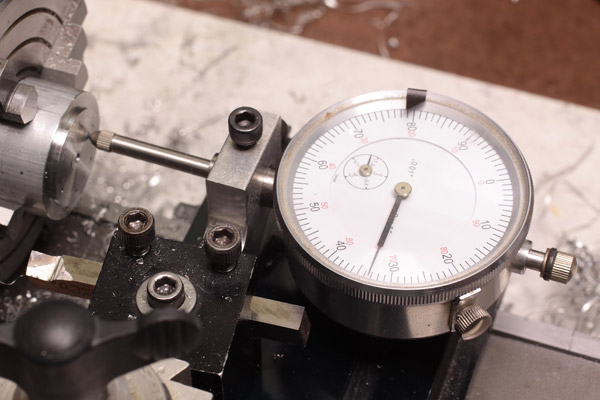

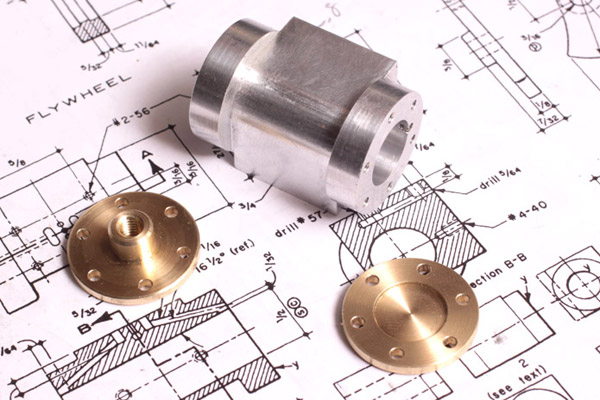

I didn't really take any photos since the process was essentially the same as before. First here is the outer blank turned to size with the small spigot to reference the bore. This fit is actually better than the original. From here I parted it off and mounted it up in the 4-jaw/split bushing combo, indicated it true and cleaned the outer face with a light skim cut. Notice in the second photo that I also created a slight recess. Why? I simply thought it looked better.

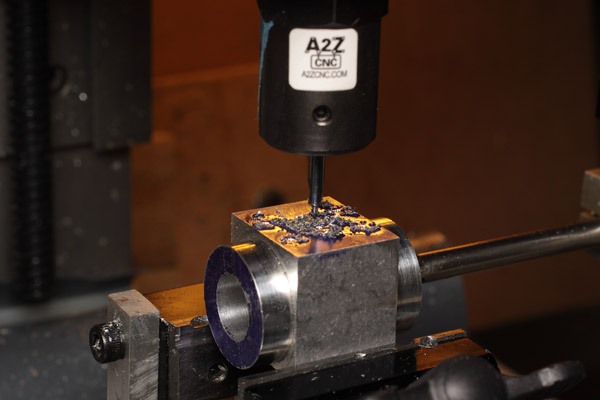

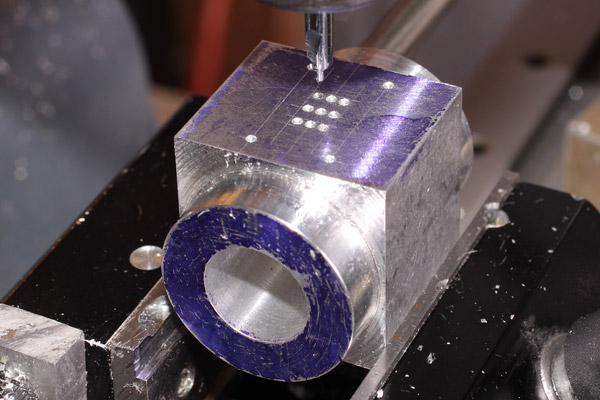

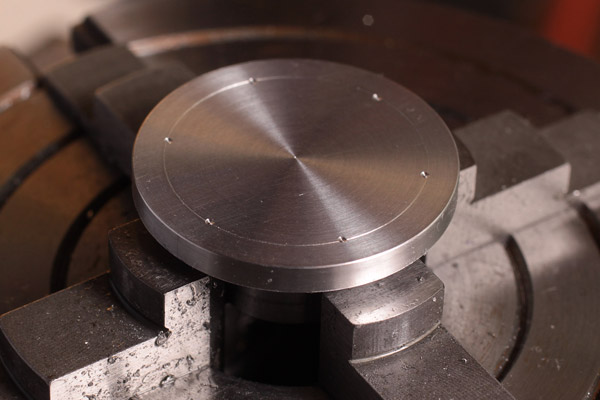

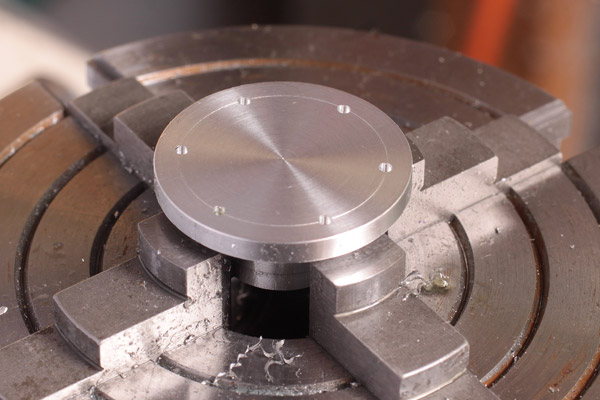

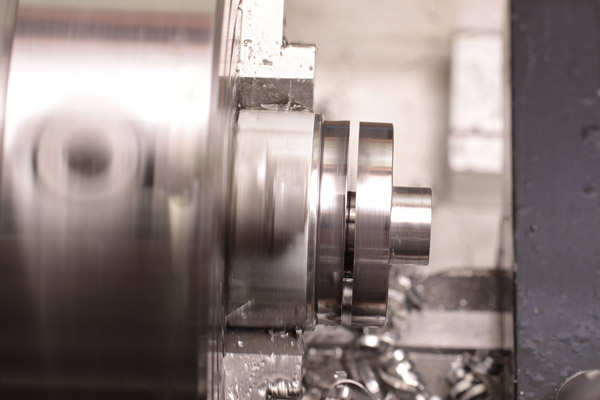

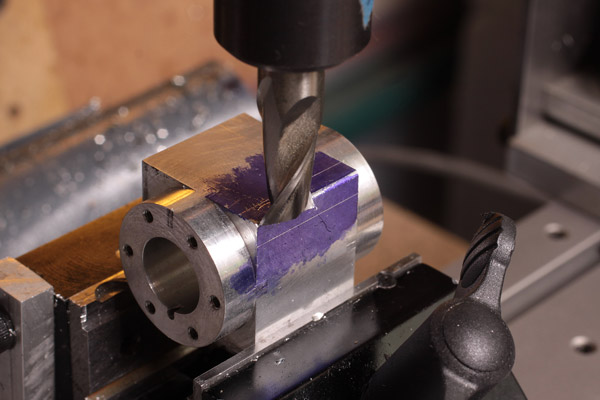

The inner head is the one that is critical. I did this by turning the spigot to receive the packnut, then drilled it for the piston rod, opened it up with the #21 tap drill and then tapped it 10-32 as indicated on the plans.

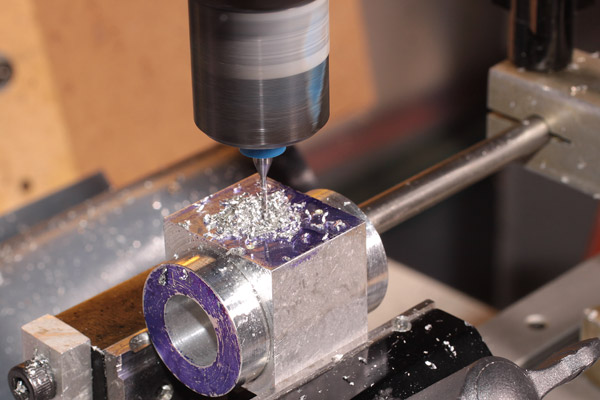

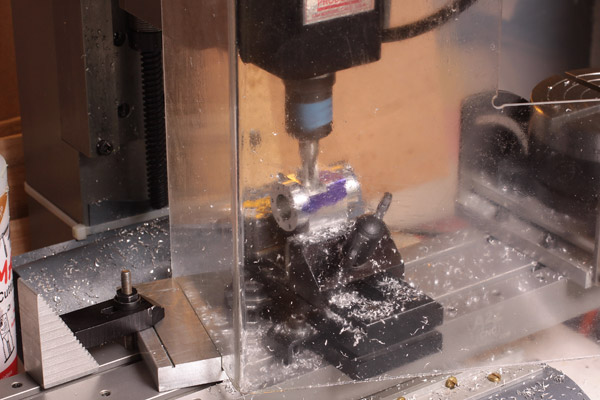

I then turned the rest of the OD before the chuck jaws down to match the cylinder head so I could reverse it and put it in the split bushing. After indicating it true I then milled the final thickness and bore spigot.

So now I have a little brass to polish on this and keep bright when I am done.