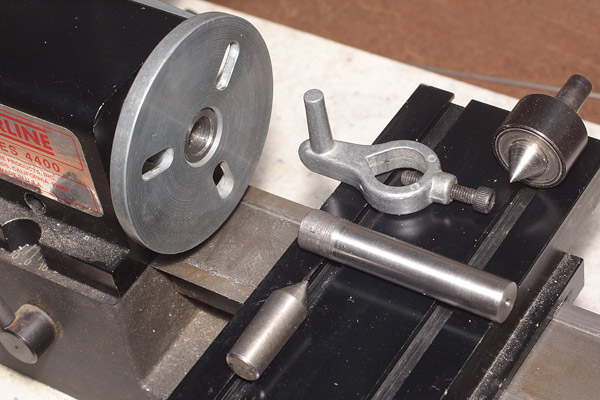

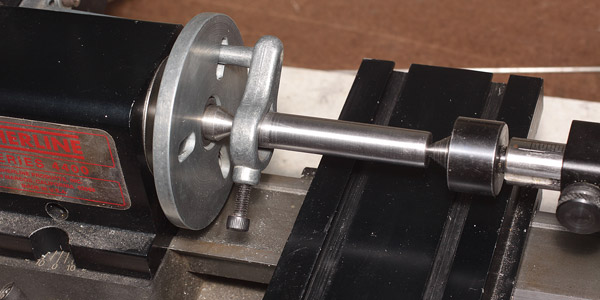

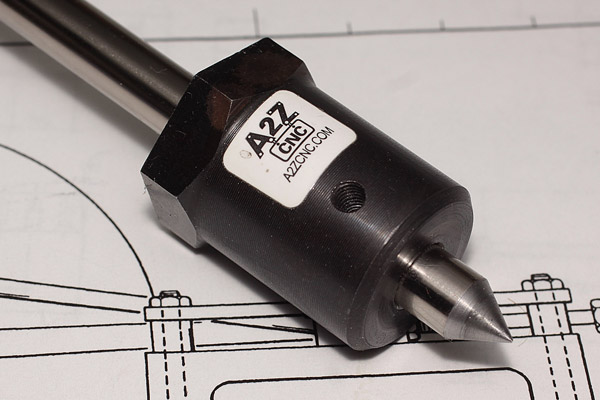

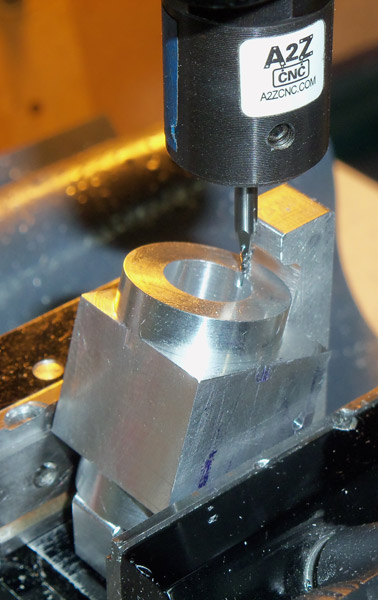

As a bit of reintroduction, I've had a manual Sherline 4400 lathe for a while and a couple years ago complimented it with the A2Z CNC Monster Mill to maintain Sherline compatibility. Knowing little of operating a mill or CNC at the time, after a few basic bits and pieces I christened it with a couple of Elmer's simple engines, a #25 wobbler followed by the #2 twin vertical wobbler, seen here.

http://www.homemodelenginemachinist.com/f14/elmers-2-25-a-8201/

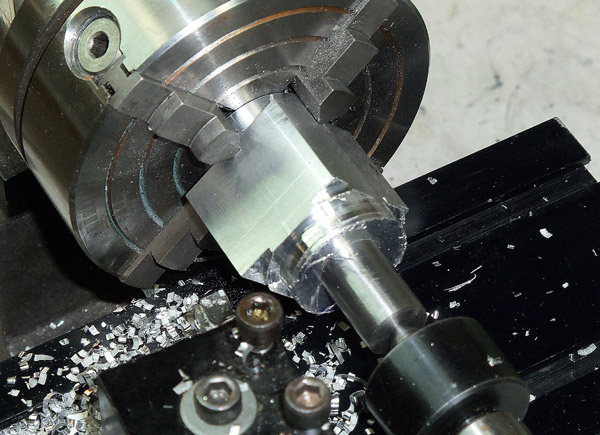

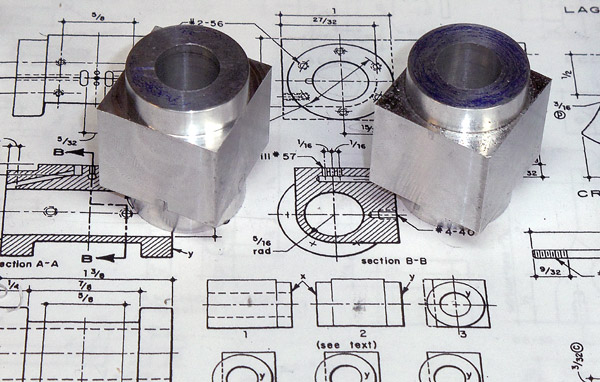

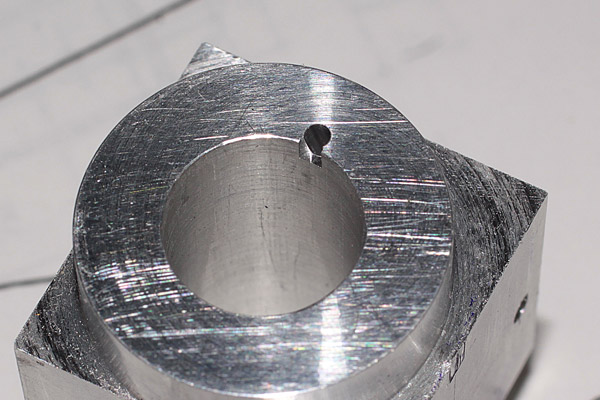

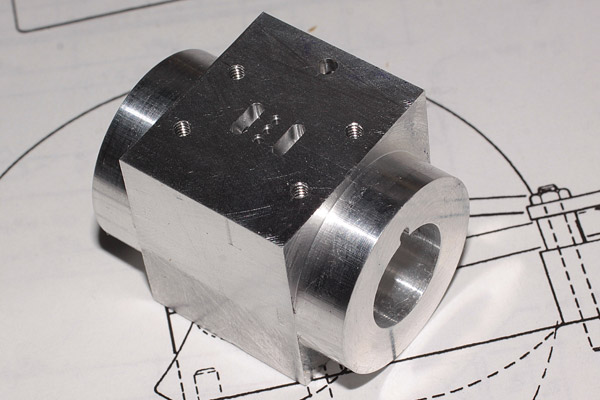

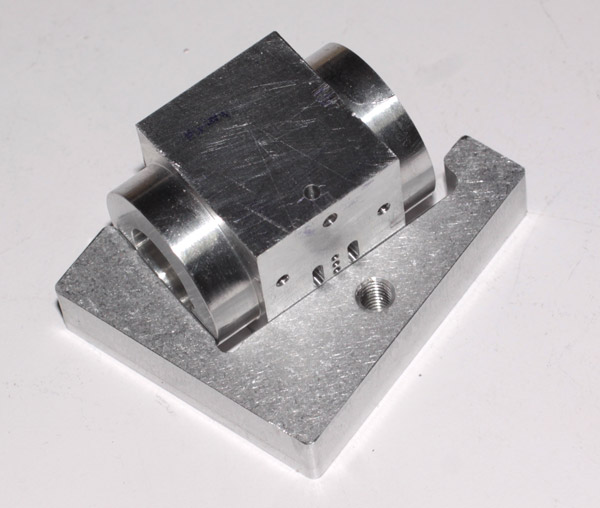

While the main use of the tools has been making bits and pieces for my radio control airplanes, I have long meant to revisit Elmer's catalog and tackle something a bit more complex. A few days ago I did just that. I've now begun his #33 horizontal mill engine and began with the cylinder block to see right away if I was up to the challenge. I'm not fast with my projects, but try to build cleanly and accurately. I will update this thread as I go but am rather sure that life will keep it from running this year.

My main goal, beyond finishing the mill engine of course, will be to pass along a bit of inspiration to others like me who are new to machining. This forum can be at once both inspiring and rather intimidating. I've found twice in the past, and expect to again, that you don't need to be a master machinist to enjoy turning out a working steam engine.

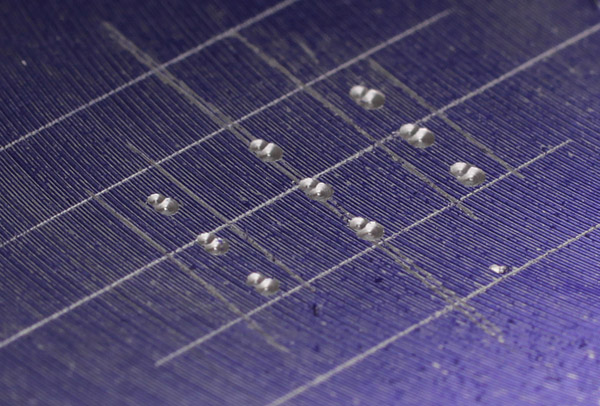

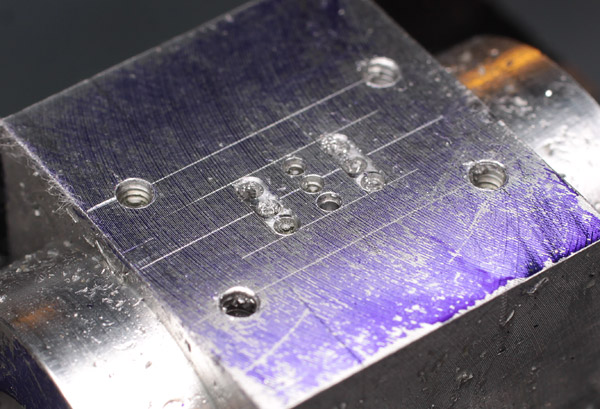

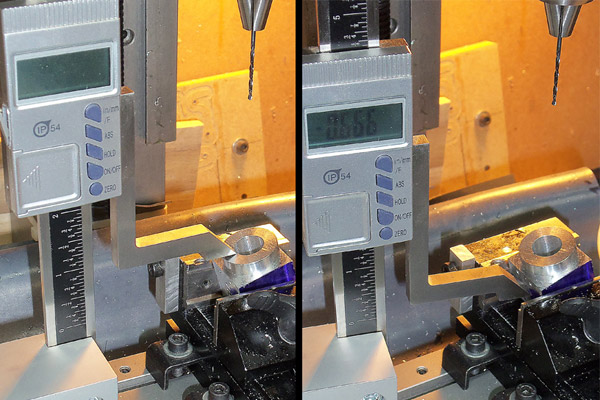

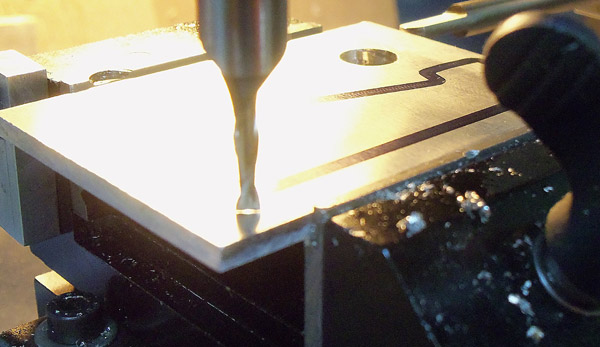

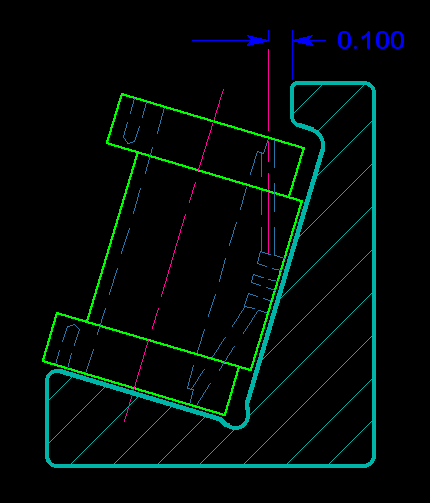

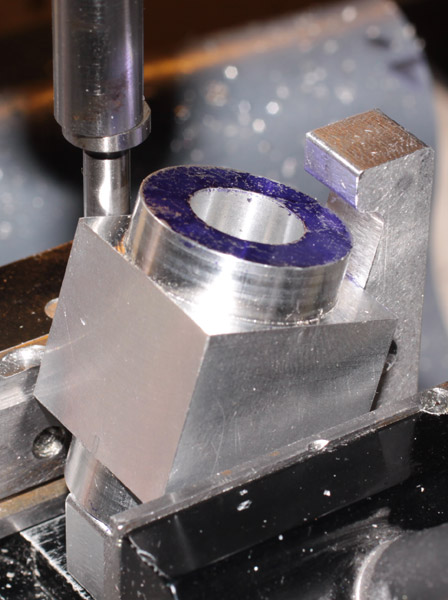

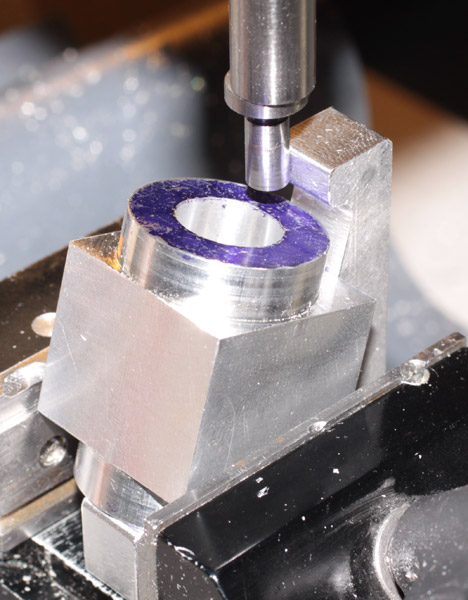

This first photo shows the basic start. My scrap stock was a little oversize, so I made a several passes with the Sherline flycutter to bring it down to its nominal cross section of 1x1 inches. Note the slight relief in the top of my vise jaws. Inspired by Tryally's slim vise, I inverted the stock jaws and milled the relief as a "permanent" set of parallels. I will occasionally skim them when I can't indicate them accurately. Note the layout ink and scribing. I decided to lay out this project as accurately as possible, despite the availability to just use the DROs and run some G-code.

Of note to those still sitting on the fence is the piece of wood used to contain some of the fly cutting swarf. I have a stash of used breaking boards from our local karate studio, gathered after one of their semi-annual black belt testing sessions. If an 8 or 9 year old kid can earn an internationally recognized black belt after 4 years of training, surely we can muster enough confidence to carve a little aluminum and brass.

http://www.homemodelenginemachinist.com/f14/elmers-2-25-a-8201/

While the main use of the tools has been making bits and pieces for my radio control airplanes, I have long meant to revisit Elmer's catalog and tackle something a bit more complex. A few days ago I did just that. I've now begun his #33 horizontal mill engine and began with the cylinder block to see right away if I was up to the challenge. I'm not fast with my projects, but try to build cleanly and accurately. I will update this thread as I go but am rather sure that life will keep it from running this year.

My main goal, beyond finishing the mill engine of course, will be to pass along a bit of inspiration to others like me who are new to machining. This forum can be at once both inspiring and rather intimidating. I've found twice in the past, and expect to again, that you don't need to be a master machinist to enjoy turning out a working steam engine.

This first photo shows the basic start. My scrap stock was a little oversize, so I made a several passes with the Sherline flycutter to bring it down to its nominal cross section of 1x1 inches. Note the slight relief in the top of my vise jaws. Inspired by Tryally's slim vise, I inverted the stock jaws and milled the relief as a "permanent" set of parallels. I will occasionally skim them when I can't indicate them accurately. Note the layout ink and scribing. I decided to lay out this project as accurately as possible, despite the availability to just use the DROs and run some G-code.

Of note to those still sitting on the fence is the piece of wood used to contain some of the fly cutting swarf. I have a stash of used breaking boards from our local karate studio, gathered after one of their semi-annual black belt testing sessions. If an 8 or 9 year old kid can earn an internationally recognized black belt after 4 years of training, surely we can muster enough confidence to carve a little aluminum and brass.

Last edited: