Hi Ryan - I hope today's post will reveal the rest.

Thank you John

I'm actually also starting to enjoy making the small bits - that is when I don't drop them

And I have to agree; there's no shortcuts; it all just takes a bit of effort. "... I use for facing my nuts to size (that sounds painful),..." :big:

Double thanks Ron

I've made the nuts for nearly all my engines so far - simply because initially I couldn't buy them. As John mentioned, it can be useful to make one's own; I'm looking at my own work with an ever-more critical eye while building each engine, and I want things to look "right" - even though that is very subjective as different people's tastes differ. Thm: I'm glad you're enjoying the tooling thread as well. You'll notice I make up the bits of tooling as I need them - or in advance if I'll need them for a new project.

Thanks Ed

I'm glad there's some useful information in my ramblings. Thanks for labeling my build as "expert" - but I am just an amateur and very much still learning as I'm going along.

More work on the nuts this afternoon...

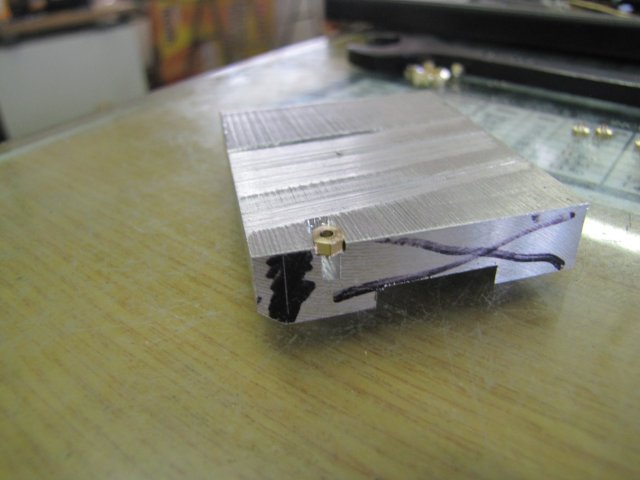

First up was a little jig to hold them for tapping; just a 2mm slot milled into a scrap bit of aluminium - to allow clearance for the tap, and widened to 3.4mm at the top to hold the nuts; I made them 3.4mm across flats:

If you have a look at the previous set of photos I posted, you'll notice that all the nut blanks still have a little parting pip on them; that's about 1.7mm in diameter and fits nicely in the tap-groove in the jig. I had a hunch that the tap would also remove the pips when threading the nuts, and that actually worked. While tapping, the tap neatly removed the pip, and when unscrewing the nut from the tap, the bit just falls off:

My "makeshift and ugly" tapping handle in the previous photo is really nice to use when tapping cylinder blocks and so on while using a tapping guide, but I found it a bit awkward for the nuts. Then I remembered I'd made a tapping handle for my M3 taps when I needed to get into a tight spot where the tap shanks were too short to use my regular tapping handle. The shanks on my set of M2 taps is the same thickness as that of the M3 taps, so I switched to that handle - it's much easier to use, and I'd made a convenient indentation on it's top to twirl against my index finger:

That made tapping really quick and easy; before a batch of fourteen nuts, I went to get a cup of coffee, and by the time I'd finished tapping all the nuts, the coffee had cooled just enough to be drinkable without scalding my mouth ;D

The nuts all still had some burrs on them from parting off; I just used a bit of threaded rod with a section of pipe to make a handle to hold onto them for cleaning up:

A quick lick with a file on each nut, then some emery, and a trip to the buff, and each nut was cleaned up in turn:

I ended up with a nice selection of nuts; screwed on threaded rod to prevent dropping them - the shop-monster must be starving, as I only dropped one nut for it to lunch on during the entire process:

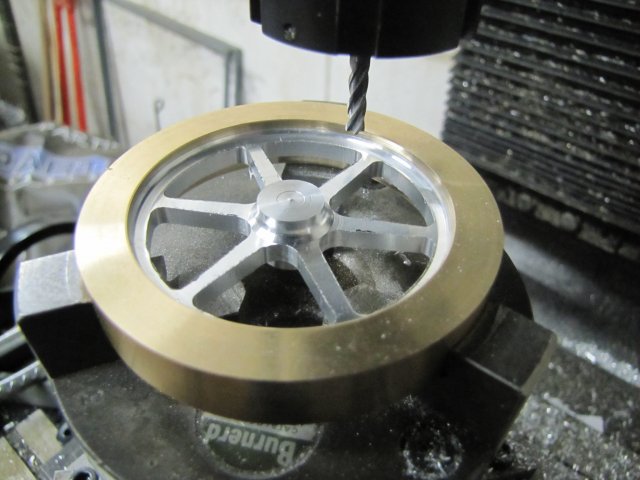

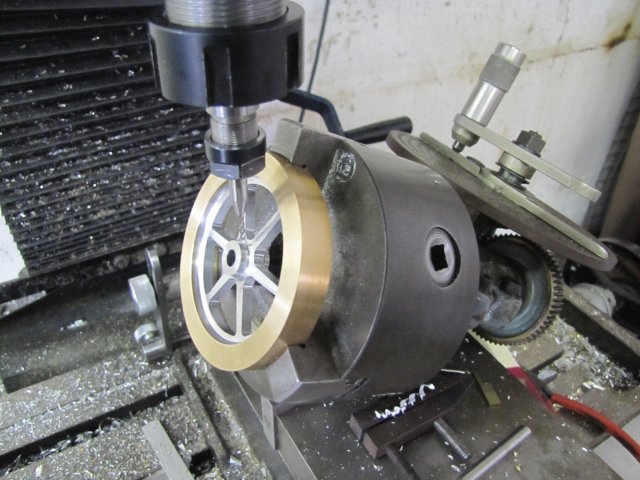

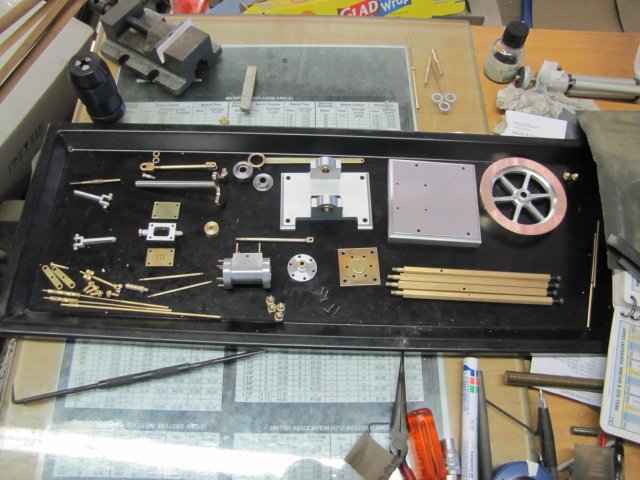

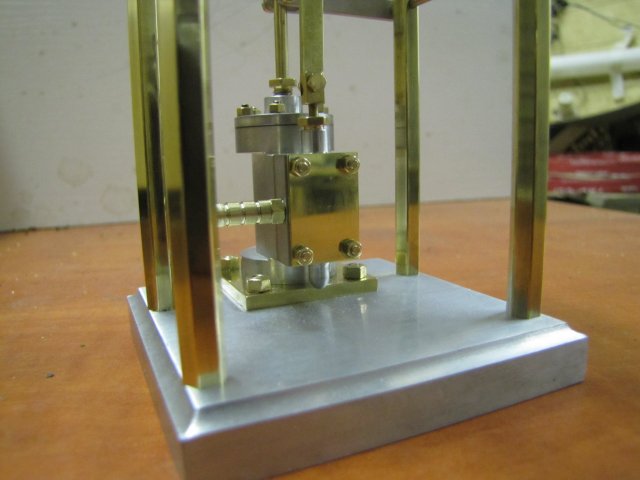

The bits needed for the engine are getting less; I had a quick scan trough the plans and made a list, and what's left is the flywheel, steam connector, and I'd somehow slipped up making the valve and it's nut so far. The cylinder base mounting screws are also outstanding; I can't make up my mind whether I want to make those as studs 'n nuts or use dome nuts to match the column nuts...

So back to the original intent of this build, and a try-out of the pocketing feature of the DRO while making the valve.

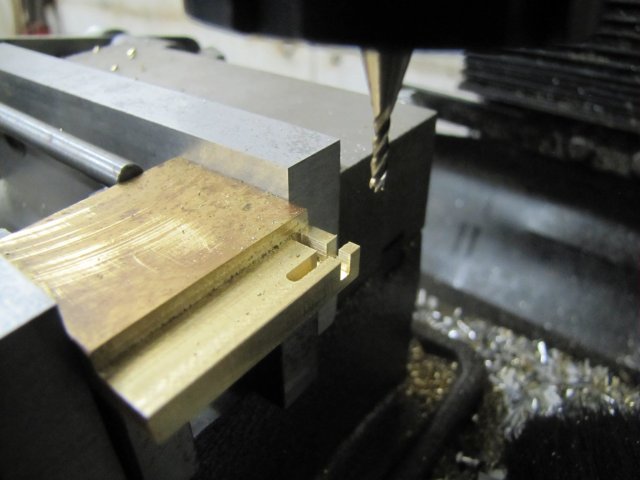

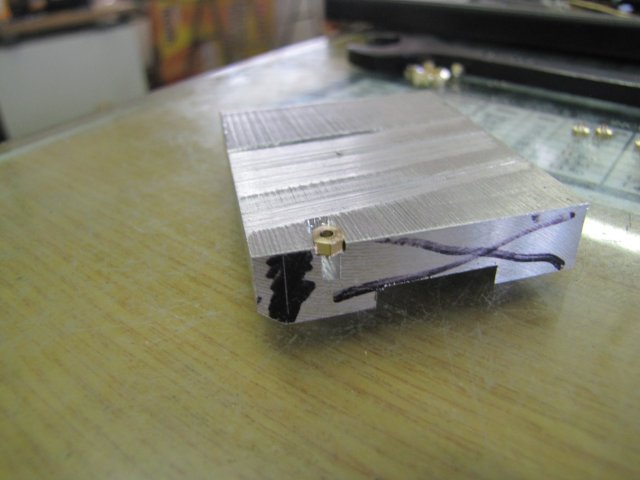

First off, I milled a bit of 8mm flat bar down to 5.16 mm on one side - that's the thickness of the valve - and then milled the slots for the valve nut and valve rod clearance; these are both 2mm wide - adapted a bit from Elmer's dimensions to match my valve rod and some 2mm plate I'll make the nut from:

Then I flipped the block, and milled the pocket using the DRO's feature. It's really easy to use; one enters the size of the milling bit, the center point of the pocket, and it's X and Y dimensions, and the DRO tells you to which positions to move while milling to hack out the pocket in a sort of square spiral fashion. What I found interesting was that it looks like the DRO software also compensates for the cutter thickness in terms of it's diameter while cutting; I used a 2mm cutter, and the coordinates were spaced to only take 1mm off each side, and amazingly, to conventional mill all the way ;D

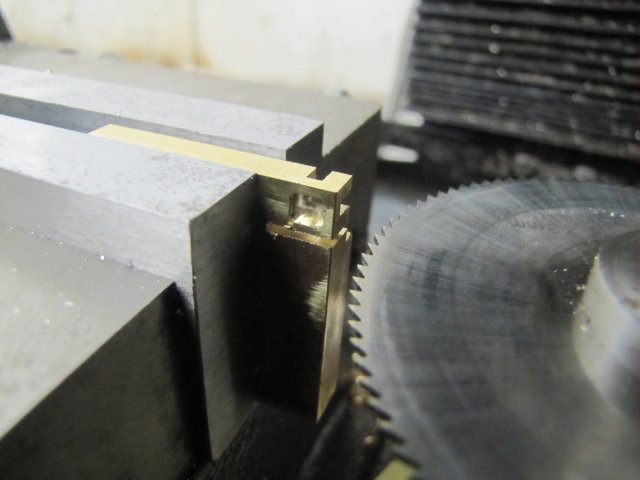

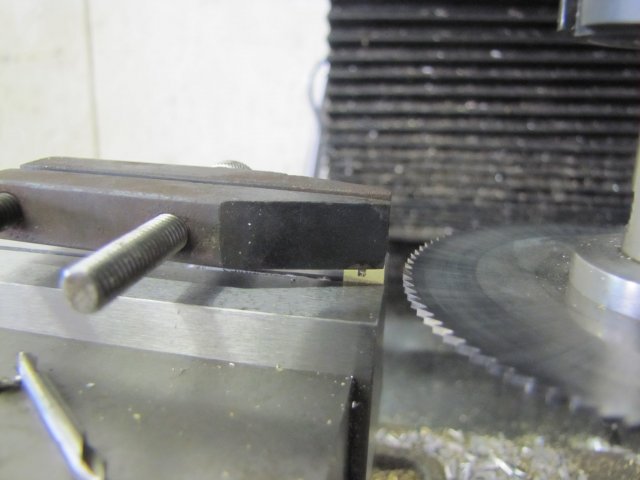

I then used a slitting saw to slit the valve off the parent stock:

The completed valve, after a bit of clean-up work and flat-lapping the port face:

I'm not entirely happy with it; the one side looks like it's narrower - that's because of the chamfer on that side; I didn't notice that chamfer while machining the stock :

The valve will work, as that chamfer is on the "side" and will not impact while in operation; if it was on one of the edges joined to that side, it would make setting the valve position very difficult... Maybe I'll just re-make it to get it spot-on.

Kind regards, Arnold