Today is the first time in two months that I haven't been dying from lower back pain.--I didn't stand for hours at the lathe or mill today. What a strange coincidence!!! Instead goodwife and I made the 200Km trip up north to see my 89 year old aunt and my 98 year old mother. Aunty is just a bright and sparkling as she ever was. Mom---Well, mom isn't doing too well. She did know me and Aunty, wasn't real sure about goodwife until I reminded her. She isn't in any pain, but is a bit befuddled. She is very well cared for in the seniors home where she lives. Tomorrow I will pull the new cylinder head off the engine (Only four bolts to remove) and start chasing down air leaks. The valve and cage assemblies weren't really a hard press fit into the new cylinder, so I doubt that I have distorted anything. I may get out my jar of #600 compound and lap them both a bit. Due to the nature of this cylinder head, I can't get the valves out again, but I can access the valve stems and get my finger chuck on them to lap them into the seats a bit. There could be some Loctite on the valve faces or seats.--It was messy getting the loctited valve assemblies into the head. Nothing is stuck, that has to move. The valves sealed tighter than a ducks butt in the previous Frankenhead, so nothing should really have changed.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Design and build side-shaft hit and miss engine from bar stock

- Thread starter Brian Rupnow

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Thank you Johno. Redryder--Sorry, didn't see your post until just now. I used to read the Red Ryder comic strip in the old Family Herald newspaper when I was a kid. You were asking about a reason to tear down a running engine. I have four hit and miss engines that I have built, the Odds and Ends designed by Philip Duclos, the Kerzel, designed by David Kerzel from Florida, the "Whatsit" engine by Philip Duclos, and the original Rupnow hit and miss which I designed and built about 10 years ago. They all "Sorta, Kinda" work. I like to push myself into new areas of engine design, and with this current engine I am doing exactly that. Prior to this I had never designed or built a side-shaft engine. I had never designed nor machined a face cam. Those were two new things that were successes. The hit and miss function was a marriage of one kind of governor and a separate kind of valve lockout mechanism, and they did work but not as well as I would have liked. Now that I don't do a lot of professional engineering design work, I have to fill up the days with something, and this engine research is something which pleases me.--Brian

Just so you can see what I'm dealing with---I pulled the cylinder head off this morning, took off the valve springs and retainers, and lapped both valves, first with 350 grit, then again with 600 grit. You can see the dull ring around one of the valves which is the actual contact surface that touches the valve seat. Now, using the old "blow your guts out test",if I hold the exhaust valve closed and blow in the exhaust pipe, it is completely air-tight--no air gets past the valve. If I hold the intake valve closed and blow into the carburetor air inlet, again things are absolutely air-tight. I even called my tool shop this morning and asked them about ordering a new finger chuck for me.

Head is back on engine. Good compression. Same old, same old, fires just great with drill, dies away when drill is removed. I'm running out of things to try here. Last resort is a different carburetor.

Brian, what kind of fuel does this engine run on?

Since I don't recall seeing anything about an oil pan and pump, I gather there's a mix of fuel and oil? Is that a critical ratio?

Since I don't recall seeing anything about an oil pan and pump, I gather there's a mix of fuel and oil? Is that a critical ratio?

Okay--Here we go. First run with third head design on it. This has not been an easy engine. I am having a difficult time getting "sustained runs". This video truly is the first run that lasted longer than 20 seconds. It ran for about 5 minutes before slowing down and stopping. In this video the hit and miss is not hooked up yet. I have to get the engine to run more predictably and constantly before worrying to much about hitting and missing. Bob--the engine runs on Naptha gas with a bit of oil added to it to lubricate the piston. It is not a critical mixture.

After a LOT of investigating, remeasuring everything, I found that the exhaust cam had only .094" of lift, not the 0.156" that is called for. The previous video shows the engine running with the bad cam, but I simply couldn't get the repeatability and consistency I need. Once I switched to a cam with the required lift, everything settled right down and now I can run the engine until I shut it off with the switch. Jeez, what a struggle. I don't know how I made the bad cam--must have miss-measured is all I can think of. Tomorrow I will reconnect the hit and miss mechanism. This is a huge relief, finding out what was wrong. Ringo--Each engine is different, and even without a throttle each engine will find it's own "happy rpm" to run at. You can speed it up or slow it down (some) by adjusting the needle valve, but ultimately you want to find at what rpm the engine is happiest and leave the needle valve in that position when you hook up the hit and miss mechanism. Some engines will run in an acceptable rpm range without a throttle, while some will spiral completely out of control, scaring you half to death and have you grabbing for the shut off switch. I am running on a temporary gas tank right now, so I have to switch back to the proper tank and anti-backflow valve and make sure everything still operates correctly.

And here we are---correct exhaust cam, third and final cylinder head, and using the original base mounted gas tank and anti-backflow valve.

nel2lar

Well-Known Member

Brian

It is h*ll when something will not do what it was made to do. You had your share of challenges and you were victorious. Be proud my friend you deserve a real big HATS OFF to you.

Very nice I'll be watching the completion.

Cheers

Nelson

It is h*ll when something will not do what it was made to do. You had your share of challenges and you were victorious. Be proud my friend you deserve a real big HATS OFF to you.

Very nice I'll be watching the completion.

Cheers

Nelson

JohnBDownunder

Well-Known Member

- Joined

- Mar 1, 2012

- Messages

- 109

- Reaction score

- 29

Oh goody.

I think it was Winston Churchill who used the phrase, "Never Give Up", in one of his speeches. That, you have stuck to, so all kudos to you. Now we all wait to see it doing the Hit and Miss dance.

As with all your posts Brian, I thoroughly enjoy the journey you take us on.

Congrats,

John B

I think it was Winston Churchill who used the phrase, "Never Give Up", in one of his speeches. That, you have stuck to, so all kudos to you. Now we all wait to see it doing the Hit and Miss dance.

As with all your posts Brian, I thoroughly enjoy the journey you take us on.

Congrats,

John B

- Joined

- Oct 1, 2010

- Messages

- 1,357

- Reaction score

- 405

Brian,

Congratulations. I have been following your engines for years and I had no doubt that you would sort this one out. As it stands you have a very smooth and steady runner without the hit and miss and I really like it like that. BUT, I like hit-and-miss action too so I'm sure I'll like that iteration of this engine as well

Thank You again for your "warts and all" posts of your progress every time. I can learn just as much from your troubleshooting as I can from a totally-successful-every-time build.

--ShopShoe

Congratulations. I have been following your engines for years and I had no doubt that you would sort this one out. As it stands you have a very smooth and steady runner without the hit and miss and I really like it like that. BUT, I like hit-and-miss action too so I'm sure I'll like that iteration of this engine as well

Thank You again for your "warts and all" posts of your progress every time. I can learn just as much from your troubleshooting as I can from a totally-successful-every-time build.

--ShopShoe

- Joined

- Sep 2, 2011

- Messages

- 1,367

- Reaction score

- 362

Very nice. complex head design and nice to watch it run.

Okay fellows---This is it. Engine starts, runs, hits, and misses. I will continue to fiddle with things which should provide less hits and longer misses, but the engine and hit and miss features are completed. This has been an interesting 9 week thrash, I've learned a few things, been surprised a couple of times, and been frustrated beyond all belief at times. All of the difficult stuff has been sorted out, and drawings updated as I went along. If you are a skilled engine builder with two or three internal combustion engines under your belt, this would be a great engine to build. No castings are involved, just bar stock. Thank you all for following the build and commenting. If you want to buy a set of plans (there are about 50 drawings), Send $25 Canadian funds to my Paypal account where I am registered under my email address [email protected] I send out my drawings electronically, as .pdf files soo that you need no proprietary software to open and read them.---Brian Rupnow

Congratulations Brian on another great episode of watching Brian create an engine. Thanks you for sharing.

- Joined

- Sep 19, 2015

- Messages

- 274

- Reaction score

- 80

Congratulations Brian. She runs like a charm.

Cheers

John

Cheers

John

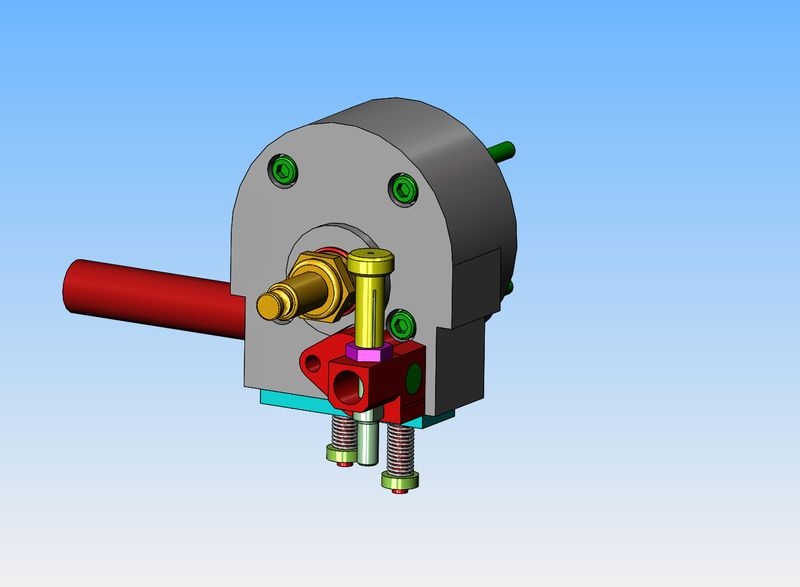

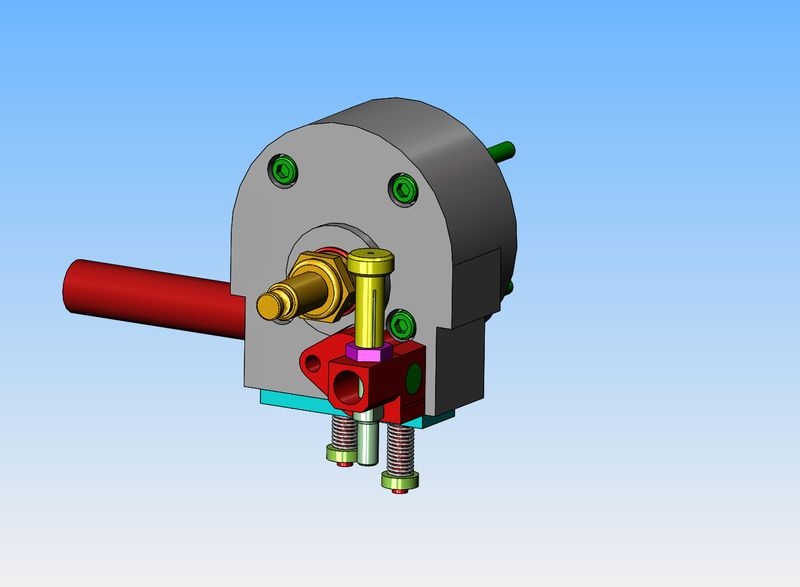

Synopsis---I'm glad this engine is finished. I'm somewhat disappointed that it doesn't have a better hit and miss ratio. Biggest finding is that when you add in a set of helical gears for the sideshaft and a set of bevel gears for the governor, the engine "coasts" like a lead balloon. With or without the Viton o-ring on the piston this engine does not coast well.--at least not with 6" diameter flywheels. On a full size engine or on a larger scale model with possibly 8" flywheels and a 1.25" bore piston I'm sure that the "coasting" would be greatly improved. The governor works very well. It is rather complex, but it does function better than I had thought it would, and is very sensitive to changes in rpm. I have always had a sense of great "mystery" when it comes to face cams, but after the first rendition of this engine with a face cam, and thanks to help from a couple of forum members, I wouldn't be afraid to design and machine a face cam again. This is the first engine I have ever built with an "internal" fuel tank mounted in the engine base. It worked out very well, and the anti backflow valve I designed and built really does work well, and keeps the fuel from draining back into the tank when the engine is in "miss" mode. The strange "Frankenhead" I designed and built to allow installing the valves from the top of the cylinder head didn't work. I never really come up with an exact answer as to why it didn't work, but I surmise that the burn chamber created was simply to large. The third and final cylinder head, in which the valves, valve cages, springs and retainers were inserted as "sub assemblies" really did work out well. I had never thought of doing it that way, and I give thanks to "Ringo", a relative newcomer to one of the forums I post on for suggesting it. The basic structure of the engine including the water reservoir, sideplates, base, crankshaft, and ball bearings is pretty standard fare for this type of engine, as are the cylinder piston and connecting rod. It's been an engine which provided me good entertainment for two months or so, and made me stretch my machining abilities to a higher level. Thank you to everyone who stopped by, said Hi, or even had a look at what I was doing.---Brian Rupnow

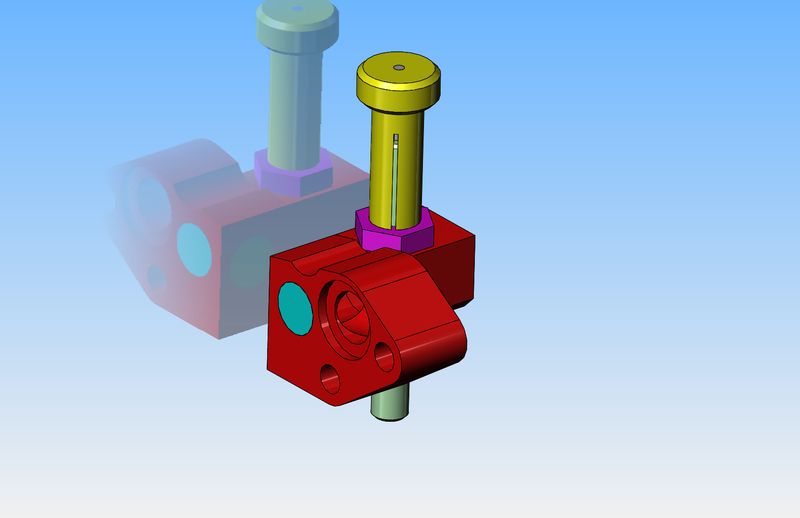

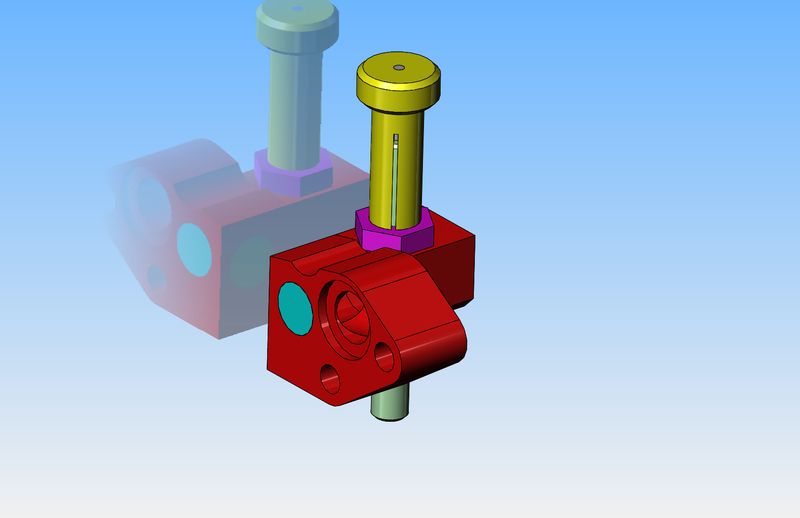

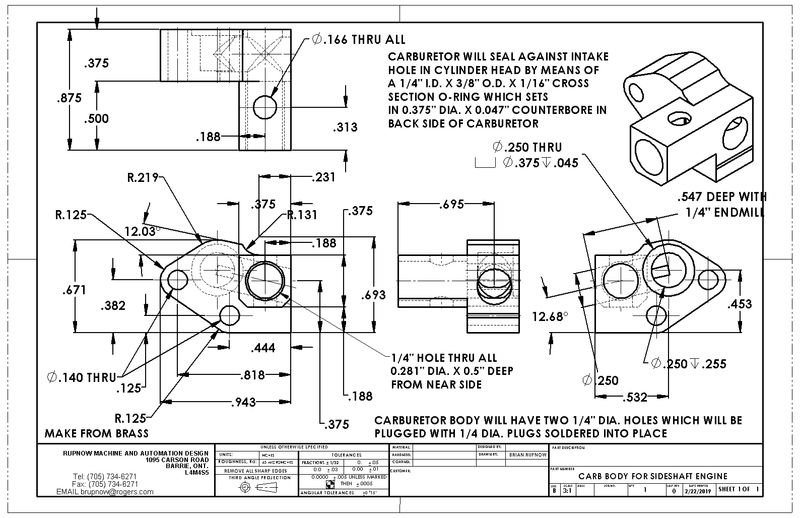

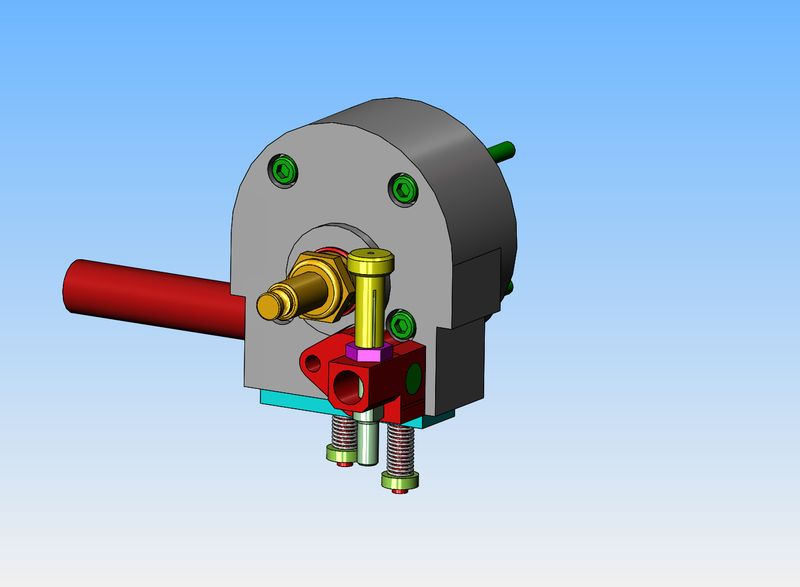

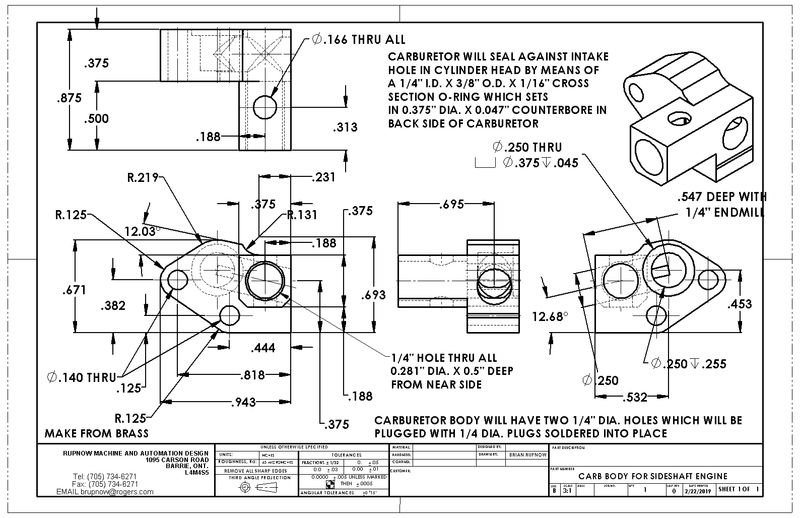

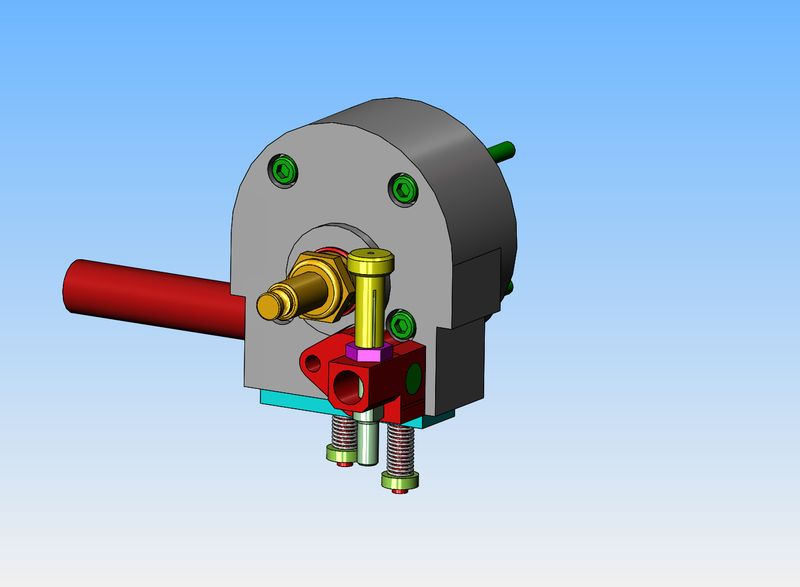

When I built this engine, I "borrowed" a carburetor from one of my other hit and miss engines. Now that the main build fever has tapered off a bit, I will build a new carburetor specifically for this engine. I had a few issues with carburetor placement, necessitated by going rapidly thru three different head designs. I don't really want to make any more changes to the final third head, but I do want a carburetor that sets up really close to the head and has adequate clearance from the sparkplug. This design, although it requires a clearance notch on the land which centers the sparkplug in the head and a couple of tapped #6 holes, gives me everything I wanted. It sets up close to the head, it has adequate clearance form the sparkplug, and it's not going to get whacked by the revolving cam.--And best of all, I found a piece of brass big enough to make it in my "brass drawer".

The carb body, while small, ends up being quite complex.

Very entertaining to watch, Brian, so congrats on a nice running little engine. I've watched that video twice already.

How old is the concept for hit and miss regulation of RPMs? Pretty sure I told you I had never seen or heard of one until my first encounter with one at NAMES. I'd guess it must be during the early adoption of the IC engine, so late 1800s?

How old is the concept for hit and miss regulation of RPMs? Pretty sure I told you I had never seen or heard of one until my first encounter with one at NAMES. I'd guess it must be during the early adoption of the IC engine, so late 1800s?

CFLBob---Google is your friend. I don't really know off the top of my head. Probably mid 1800's.---

https://en.wikipedia.org/wiki/Hit-and-miss_engine

https://en.wikipedia.org/wiki/Hit-and-miss_engine

Similar threads

- Replies

- 148

- Views

- 24K

- Replies

- 5

- Views

- 2K