Bits and pieces, pieces and bits. I just finished the cylinders, except for about a million holes yet to be drilled. About the cylinders--I called Barrie Welding and was quoted $40 over the phone for 4 1/2" of 2" diameter cast iron. I went down to pick it up, and they wanted $50. Of course I said that I was quoted $40 over the phone. --And the guy said---"Oh yeah, but there is a $10 cutting charge". I paid, but I don't think I will be buying any more material from them.

I had a similar experience once. Quoted a couple of quid for the material, then an additional 5 quid for cutting. They were a little surprised when I showed up with hacksaw in hand to cut it myself.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Building a twin cylinder inline i.c. engine.

- Thread starter Brian Rupnow

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Brian was that to compensate for only having half the number of cylinder fins?

No, it was just because I like it.

Things are looking good, and assembling with no problems----but---I've lost a cylinder. I know that I made two cylinders. Too much shop time does this to me.--I begin losing things that I know I made. Time to go upstairs and read a book. Hopefully, tomorrow I will come downstairs and the missing cylinder will appear.

Brian

You left it in Post # 59. I saw it there.

You left it in Post # 59. I saw it there.

Oh... I thought it was because you were copying the engine in post #45, and decided the second cylinder wasn't needed.

Look in your scrap bin? - Usually I find all my good bits in there, and swarf on the bench....

K2

Look in your scrap bin? - Usually I find all my good bits in there, and swarf on the bench....

K2

You could photograph all the workshop and we'll have a competition to see who spots it first?

K2

K2

This morning I came down to the bat cave and proceeded with a big sweep up/clean up. Just as I had expected, the missing cylinder had leapt off the mill and then hidden under a cupboard. Today I checked my stock to see what I could use for a flywheel. I have some brass but I want to save it for something else. Then I spied a big, crusty, rusty piece of 1" thick A36 plate that I've had forever. So--Today I will carve a flywheel from it.

So what do you do when there's an all day blizzard raging outside? You spend three hours machining to save $5 worth of cold rolled steel. At any rate---I now have a flywheel!!!

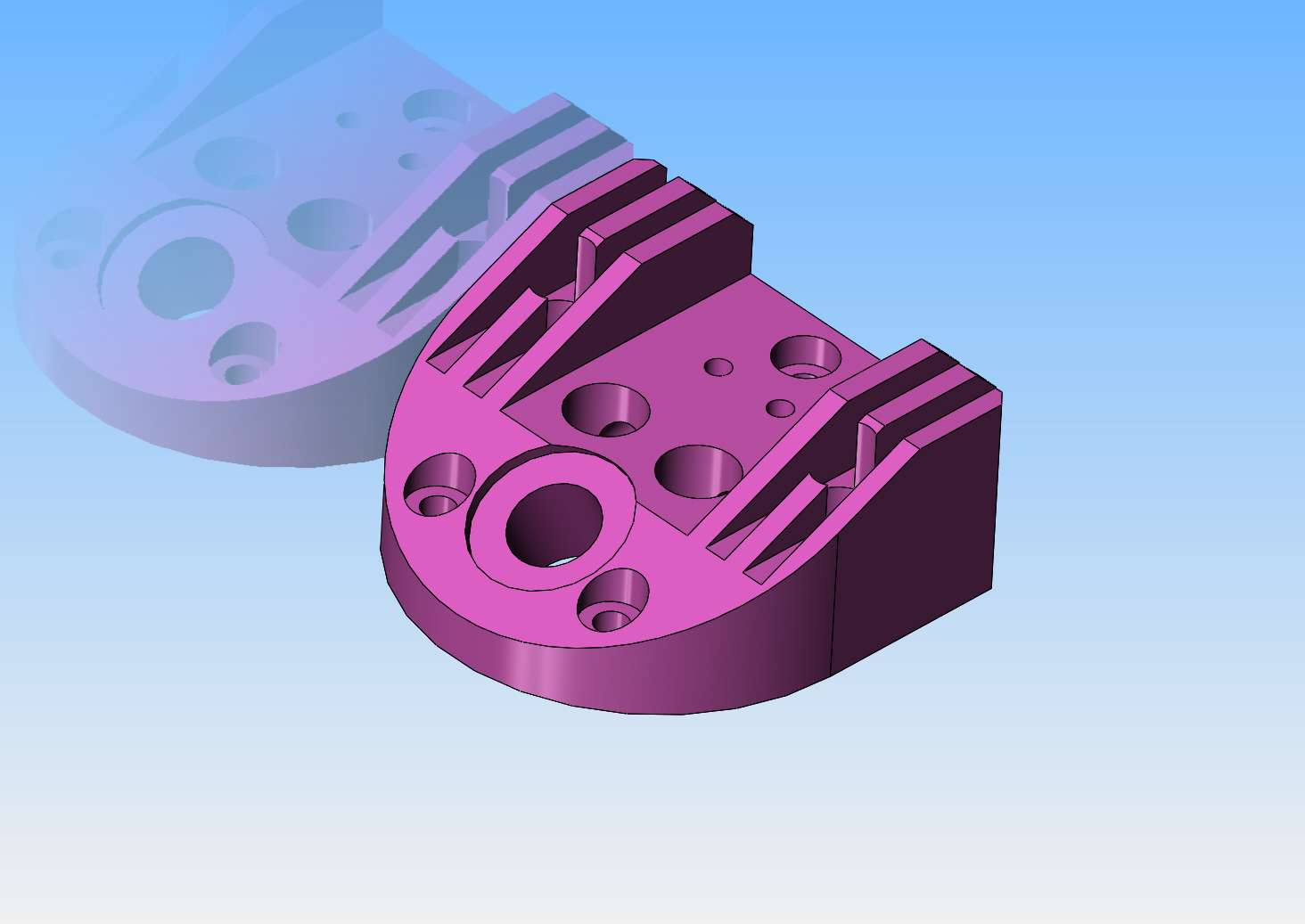

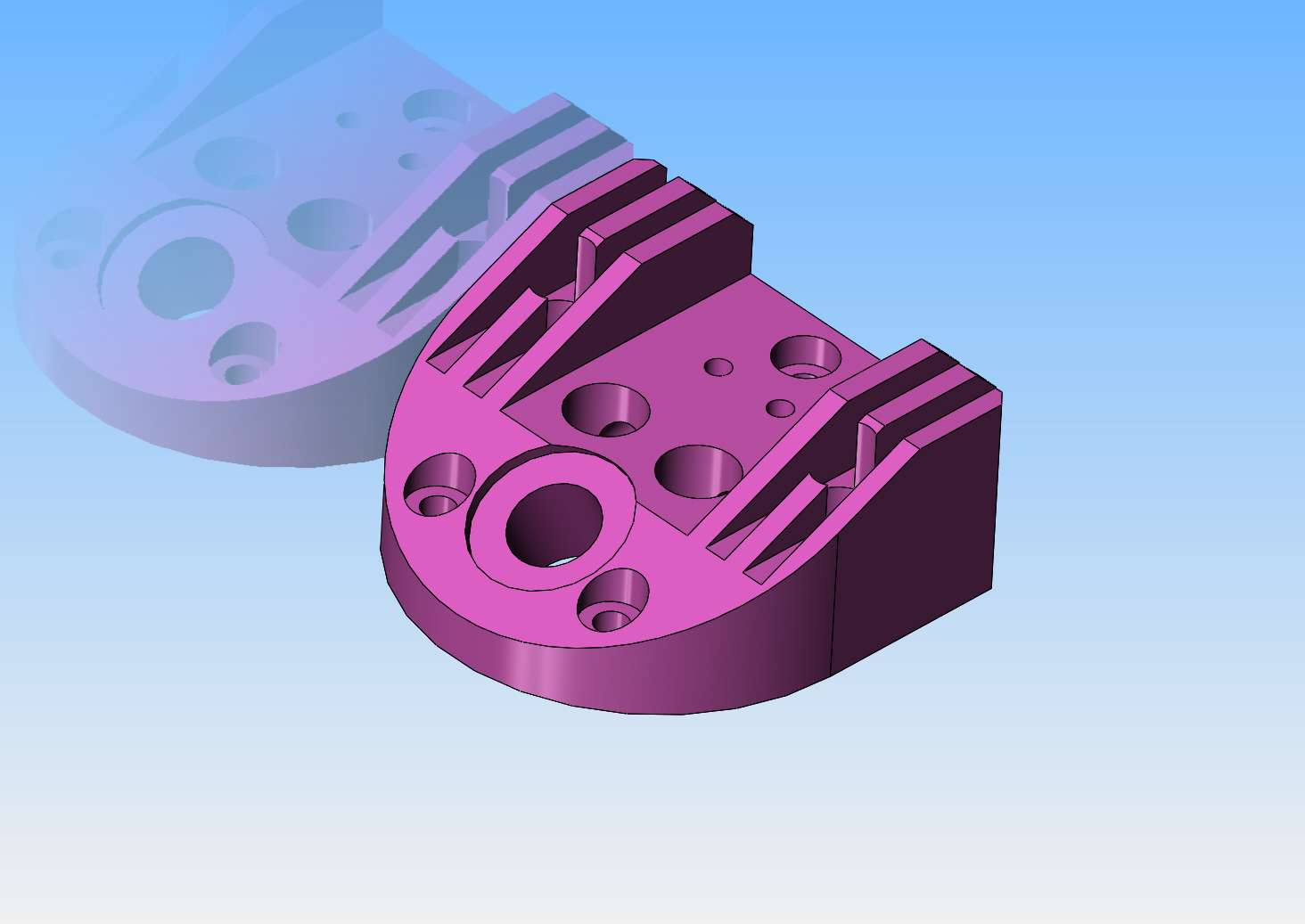

I have redesigned the cylinder head to have cooling fins. It will probably help with heat dissipation, but the big factor is that visually it makes the cylinder heads much more attractive.

Does anyone know where I can buy a sparkplug with an m8 thread on the nose? I'm a bit like Goldilocks here. M6 thread is a bit too small and M10 thread is a bit too large.---Brian

Last edited:

I am researching the ignition system for this two cylinder engine. I want to go with a cdi style ignition with two magnets, I think---. Someone had put up a link to their build of a two cylinder inline engine, I remember looking at it a few days ago, and now the link has been taken down. I'm looking for some helpful advise and guidance on this. Can someone help, please.----Brian

danallen

Well-Known Member

My suggestion is to get in touch with Roy Sholl and see if he has or can build one of his waste fire CDI units. I have one on my Hoglet and it's great. His website does say getting components is getting harder but it's worth asking.

Thanks Dan, I will try that.---Brian

I couldn't let the entire day go by without machining something. I spent the biggest share of today researching ignition systems. It's almost suppertime so I used up the very last of my 1 1/8" diameter cast iron to whittle out a pair of pistons. I will finish them up tomorrow.

Today I learned something. For a one cylinder engine, you can use the old ignition coil and points set up. (I knew that---that's what I generally use). For a two cylinder engine, you can use a set of old style ignition points driven off the crankshaft, and a "double ended coil", which has two ignition wires running from it to the cylinders. Since the points open every 360 degrees, the coil fires both leads, but only one cylinder is on compression stroke, the other cylinder will be on exhaust stroke, so nothing in that cylinder ignites. OR---You can use a magnet and cdi instead of the old style points. if anybody disagrees with me, tell me.---Brian

Assuming we are talking 4 stroke, that theory works on a horizontally opposed twin, one ignition every 360 degrees, 0, 360, 720 (0). I think an inline twin ends up firing differently, like 180, 540. I may have to think about that some more for it to become clear in my mind.

That is also assuming a crankshaft where the throws are 180 apart.

Looking closer at you model, it looks like you have the crank set up for 360, so your single waste spark setup makes sense to me. Carry on.

That is also assuming a crankshaft where the throws are 180 apart.

Looking closer at you model, it looks like you have the crank set up for 360, so your single waste spark setup makes sense to me. Carry on.

Last edited:

The twin lead coil/waste fire will work just fine for you as your engine fires the cylinders 360 degrees apart. The same twin lead coil/waste fire also works on a twin cylinder with the crank pins 180 degrees apart. My Titan (Doug Kelley design) fires every 360 degrees like your twin. My Silver Bullet fires the second cylinder 180 degrees after the first as I modified the crank and cam for that firing configuration. Both engines use the same twin lead coil and run fine. The Silver Bullet has two magnets 90 degrees apart driven at cam speed. The Titan has one magnet on the flywheel.

Chuck

Chuck

Brian,

It all depends on the crankshaft, if both crank pins are on the same plane(both cylinders/pistons TDC at same time) you can use one set of points, with a twin coil, if the crank pins are 180deg apart you will need two separate ign pick ups and coils. Hope this helps.

Cheers

Andrew

It all depends on the crankshaft, if both crank pins are on the same plane(both cylinders/pistons TDC at same time) you can use one set of points, with a twin coil, if the crank pins are 180deg apart you will need two separate ign pick ups and coils. Hope this helps.

Cheers

Andrew

As you were asking about distributors recently you can use a single ended coil and a distributor driven off the camshaft

Similar threads

- Replies

- 25

- Views

- 3K