You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

British 0-4-0 Toy Locomotive: he said

- Thread starter zeeprogrammer

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Sorry to hear of the problems Zee. Was it one of those china brand center drills?

vlmarshall

Well-Known Member

- Joined

- Dec 28, 2008

- Messages

- 1,138

- Reaction score

- 1

Sorry to hear about the bit of bad luck, Zeep! It gets better with time... did I ever tell ya about the time 12 years ago when I BENT a .750" endmill? ;D

zeeprogrammer said:Thanks Dean... And I'd like to make the mistakes you make. (See next post.)

You probably wouldn't!

Let me commiserate, friend Zee. (Small pics, so as not to dirty up your thread too much.)

This little (#4) counterbore was one of a set I made some time back. You can see the broken flute, and if you look close, you can see the other flutes have blunt tips. I tested them all in a piece of 1018, and at the bottom of its first hole, this one was kaput. I missed the color on the temper for this one, and next day had to spend a few hours making up a couple more of them. Re-do all my setups and all that jazz for this size.

It happens to all of us. Some mistakes are really discouraging.

Happy ending shot:

Your build is coming along great, and it seems to me that you progress in leaps and bounds.

I love your build threads, mistakes and all!

Dean

zeeprogrammer

Well-Known Member

- Joined

- Mar 14, 2009

- Messages

- 3,362

- Reaction score

- 13

Thanks Bill, Steve, Vernon, and Dean.

And now I come crawling for forgiveness...

Certainly the center drill was not true but apparently neither is my eyesight.

I thought I'd see if I could 'pick it out'...well that booger wasn't going to be picked because it wasn't there. Then I got a magnifying loop and checked the center drill...both ends are still there. (Although I was right about the first one.)

[EDIT: loupe! it's a loupe you dolt.]

There's nothing much more maddening than the feeling of a booger that you just can't get to.

Hm. Maybe things were just not true. So I tried again. Success!

So I drilled. Success!

So I tapped...the last operation mind you...but success!

Put the wheels on. Rats! Too tight. No problem...a little sand...and off we go...

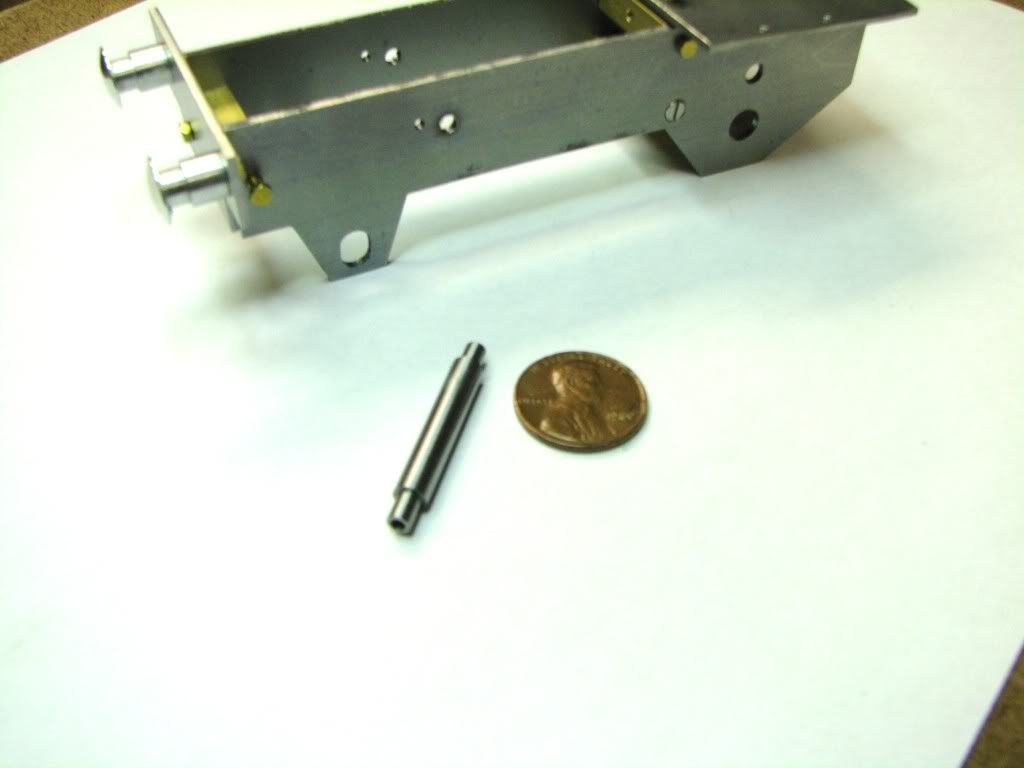

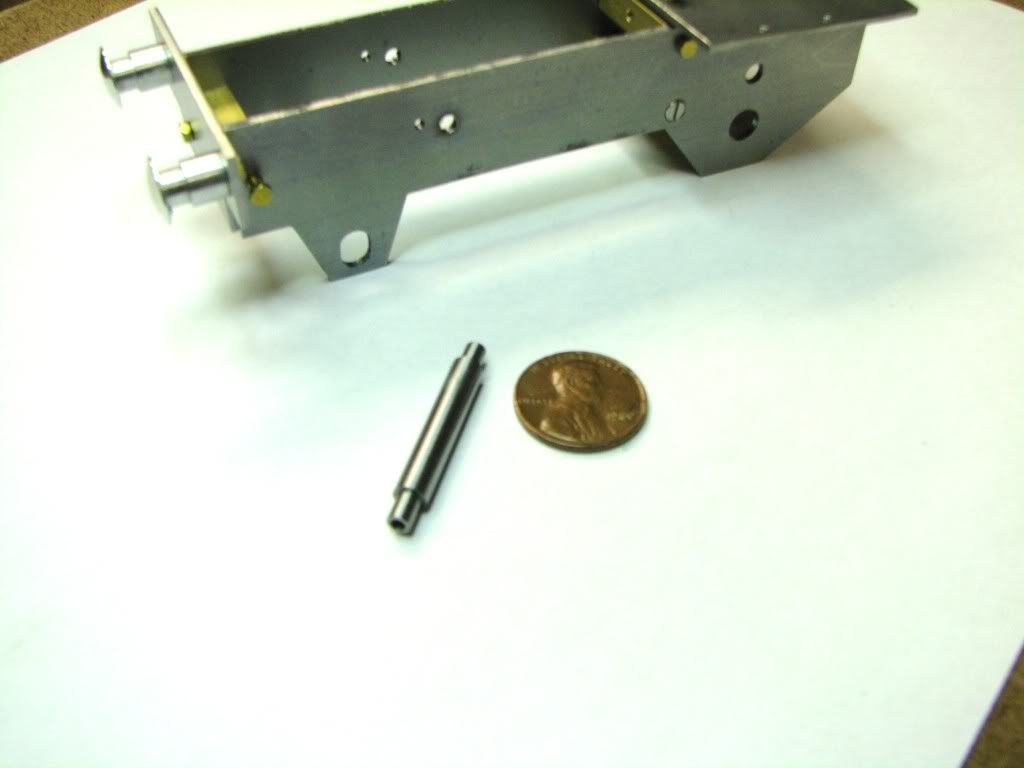

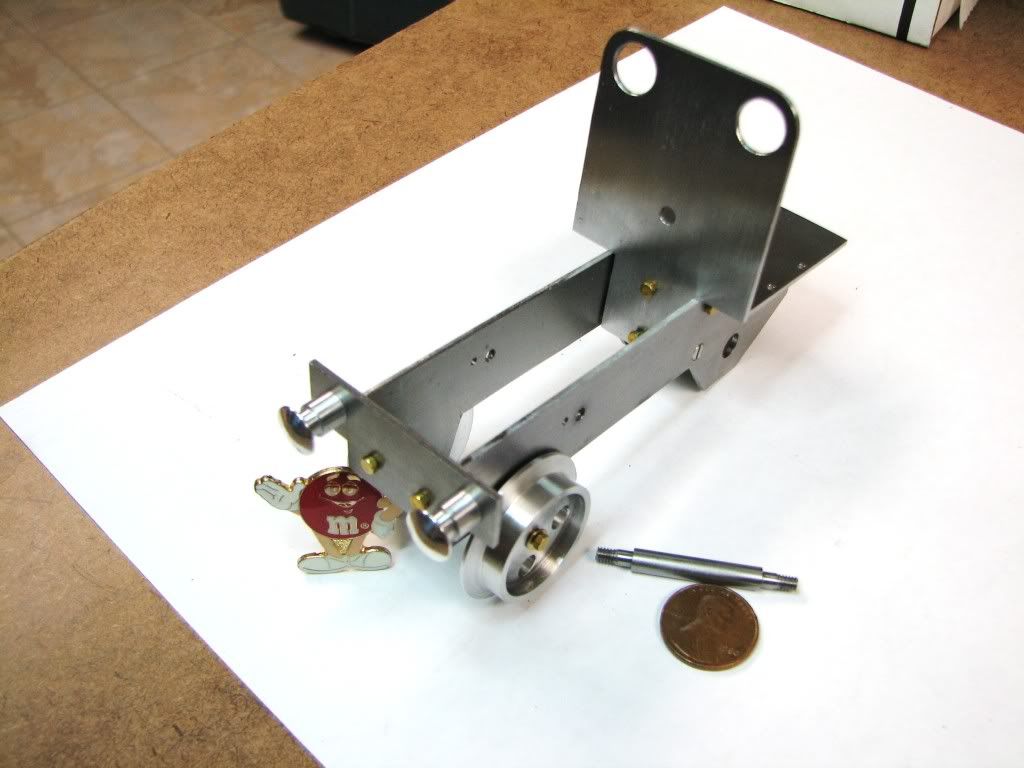

So here it is...

And mounted...

By the way Marv, I got those miniature nut drivers you suggested. Nice. $18 + $7 shipping from 'smallparts'.

Now to get my eyes checked. I did last December...got my first prescription for glasses...but it was a no go. Tried twice at Lenscrafters but still couldn't see. I think the prescription is wrong. Going to stick with the readers for another year but be more careful.

This might explain why I haven't been happy with my pics for a while.

Again, apologies for the wild goose chase...I know I'm not alone.

And many thanks to Vernon for his on-line support...he's been getting an earful (er...eyeful) from me on YIM.

And now I come crawling for forgiveness...

Certainly the center drill was not true but apparently neither is my eyesight.

I thought I'd see if I could 'pick it out'...well that booger wasn't going to be picked because it wasn't there. Then I got a magnifying loop and checked the center drill...both ends are still there. (Although I was right about the first one.)

[EDIT: loupe! it's a loupe you dolt.]

There's nothing much more maddening than the feeling of a booger that you just can't get to.

Hm. Maybe things were just not true. So I tried again. Success!

So I drilled. Success!

So I tapped...the last operation mind you...but success!

Put the wheels on. Rats! Too tight. No problem...a little sand...and off we go...

So here it is...

And mounted...

By the way Marv, I got those miniature nut drivers you suggested. Nice. $18 + $7 shipping from 'smallparts'.

Now to get my eyes checked. I did last December...got my first prescription for glasses...but it was a no go. Tried twice at Lenscrafters but still couldn't see. I think the prescription is wrong. Going to stick with the readers for another year but be more careful.

This might explain why I haven't been happy with my pics for a while.

Again, apologies for the wild goose chase...I know I'm not alone.

And many thanks to Vernon for his on-line support...he's been getting an earful (er...eyeful) from me on YIM.

Philjoe5

Well-Known Member

- Joined

- Jul 12, 2007

- Messages

- 1,727

- Reaction score

- 321

Looking good Zee. You've made a lot of progress since I poked my head in here a while ago. The parts look darn good and despite some of your online confessions about missing the mark they would never appear to be "off spec" to most (all?) of us.

Cheers,

Phil

Cheers,

Phil

mklotz

Well-Known Member

zeeprogrammer said:Thanks Marv. What did you use to hold the bit...be it ball end or X-acto?

My mega-pinvise for the mill and, for the X-acto blade... wait for it ... an X-acto knife handle. The mega-pinvise is nothing more than a 1/4" Jacobs chuck with a 6" hollow handle. Make yourself one. They're amazingly useful.

BTW, thanks for correcting the spelling of loupe. That's one of the (many) misspellings that really bugs me.

zeeprogrammer

Well-Known Member

- Joined

- Mar 14, 2009

- Messages

- 3,362

- Reaction score

- 13

Thanks Phil, Marv, Ron, and tmuir. Very much appreciated.

To be honest Marv...I'd gotten a heads up that you would jump me on the 'loupe/loop'. So I did the 'EDIT' rather than actually correct it. ;D Just to see. ;D

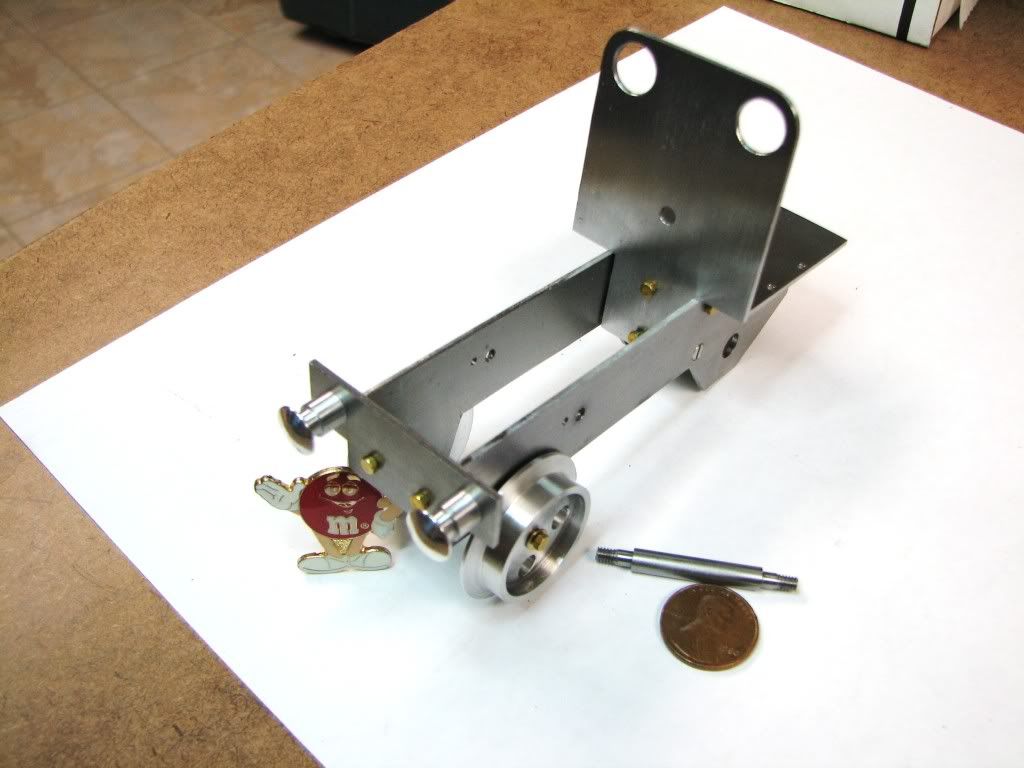

Well a little something tonight...the FRAME MID-SECTION. I played with the idea of putting it in the rotary table and milling the corners...but I ended up filing them. I sanded the thing a little...just to clean it some. It looks like I wasn't careful enough with the vise and there's lots of little dents in it. I really need to cover the vise with something (like copper sheet) and be more careful to make sure things are clean.

I did the rear axle the other night. Another short-sighted piece of work. The stock I had was enough for the front and rear axle. Silly me thought they where the same length and cut the stock in half. It turns out the rear axle is slightly longer so I ended up short by .04". Shouldn't be a problem though.

Yep stitches are out. Knee was feeling pretty good up until today. Pretty painful. Any of you that had arthroscopic surgery have the same issue? Feeling good and then can hardly walk? Any truth to being related to weather? We're expecting rain. :big:

To be honest Marv...I'd gotten a heads up that you would jump me on the 'loupe/loop'. So I did the 'EDIT' rather than actually correct it. ;D Just to see. ;D

Well a little something tonight...the FRAME MID-SECTION. I played with the idea of putting it in the rotary table and milling the corners...but I ended up filing them. I sanded the thing a little...just to clean it some. It looks like I wasn't careful enough with the vise and there's lots of little dents in it. I really need to cover the vise with something (like copper sheet) and be more careful to make sure things are clean.

I did the rear axle the other night. Another short-sighted piece of work. The stock I had was enough for the front and rear axle. Silly me thought they where the same length and cut the stock in half. It turns out the rear axle is slightly longer so I ended up short by .04". Shouldn't be a problem though.

Yep stitches are out. Knee was feeling pretty good up until today. Pretty painful. Any of you that had arthroscopic surgery have the same issue? Feeling good and then can hardly walk? Any truth to being related to weather? We're expecting rain. :big:

- Joined

- Feb 25, 2008

- Messages

- 464

- Reaction score

- 5

Zee,

Oh, nice work on the loco.

Dennis

Had the same experience with my knee. Everything was fine for awhile then knee and the backs of my legs started aching. I thought the pad on my chair had gone bad and actually went out and bought a new chair before I figured out what was going on. Not one of my brighter moves! Everything worked out in the end though.arthroscopic surgery have the same issue? Feeling good and then can hardly walk?

Oh, nice work on the loco.

Dennis

arnoldb

Well-Known Member

- Joined

- Apr 8, 2009

- Messages

- 1,792

- Reaction score

- 12

;D That's looking great Zee!

OK, so now you've proved you can file nice round corners, you can use the RT again

I know what you mean about marks from the vise - I also need to do the copper/aluminium jaw clip-ons for mine...

Hope the sore knee don't keep you from making the rear wheels for too long; that little loco is just begging to be on all fours now.

Regards, Arnold

OK, so now you've proved you can file nice round corners, you can use the RT again

I know what you mean about marks from the vise - I also need to do the copper/aluminium jaw clip-ons for mine...

Hope the sore knee don't keep you from making the rear wheels for too long; that little loco is just begging to be on all fours now.

Regards, Arnold

zeeprogrammer

Well-Known Member

- Joined

- Mar 14, 2009

- Messages

- 3,362

- Reaction score

- 13

Thanks very much Dean.

Thanks Dennis. Knee is better today...yet it's raining like the dickens.

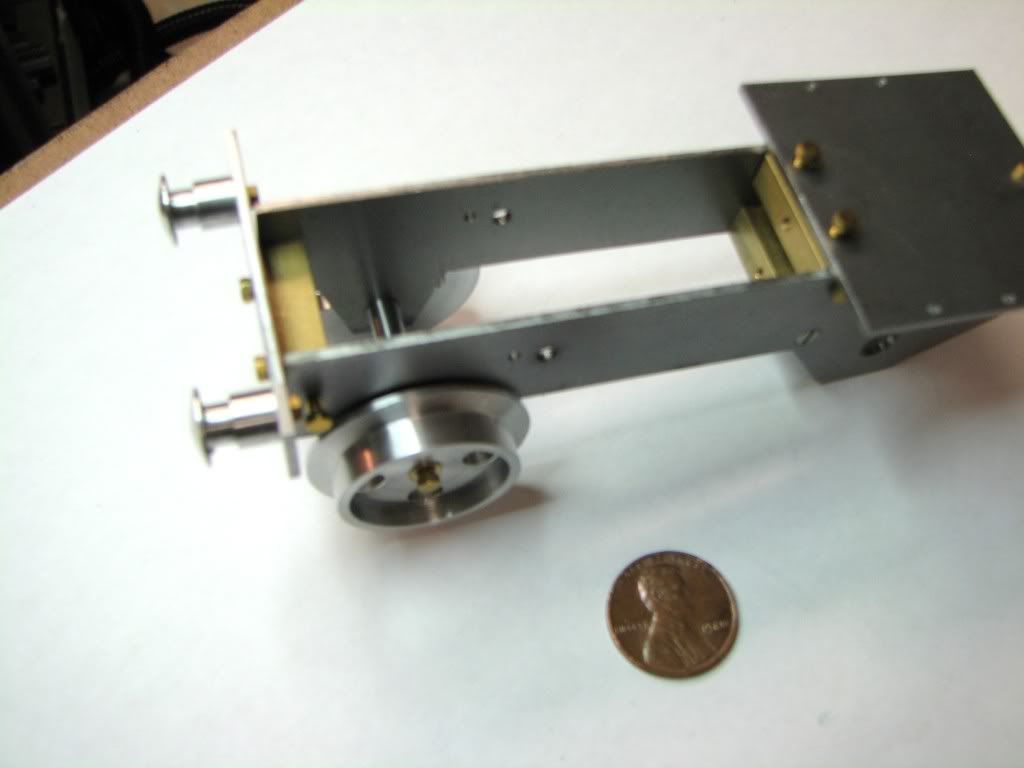

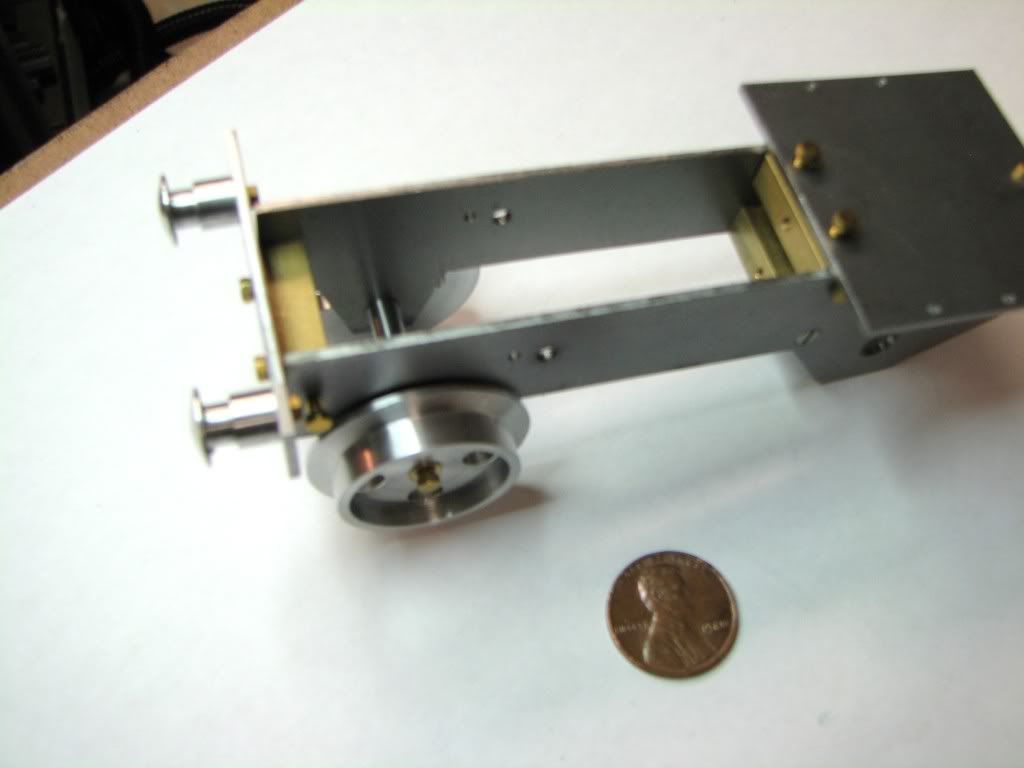

Thanks Arnold...and because of the extreme pressure you're putting on me I decided to work on the axle and bearings...

First try at this kind of press fit. It got there but not without problems and some boogering. Axle didn't fit as well as before so had to do some sanding. Very light though.

Bigger issue is that this showed I do have a problem with the alignment of the tailstock. The first bearing fits more loosely than the second. I made them off the same piece of brass...sticking out about 1/2". Made the first and then the second without moving the stock. So the first one was out further. I think I've got taper.

I hope to do the drive wheels next. Also need to start on the cylinders.

I've been told by a number of people that I wear a tutu much better than the little guy there.

Thanks Dennis. Knee is better today...yet it's raining like the dickens.

Thanks Arnold...and because of the extreme pressure you're putting on me I decided to work on the axle and bearings...

First try at this kind of press fit. It got there but not without problems and some boogering. Axle didn't fit as well as before so had to do some sanding. Very light though.

Bigger issue is that this showed I do have a problem with the alignment of the tailstock. The first bearing fits more loosely than the second. I made them off the same piece of brass...sticking out about 1/2". Made the first and then the second without moving the stock. So the first one was out further. I think I've got taper.

I hope to do the drive wheels next. Also need to start on the cylinders.

I've been told by a number of people that I wear a tutu much better than the little guy there.

vlmarshall

Well-Known Member

- Joined

- Dec 28, 2008

- Messages

- 1,138

- Reaction score

- 1

bearcar1 said:yes but the pumps don't go with that outfit and you forgot the broach. ;D

Don't encourage him! :big:

Great LOCOMOTIVE PARTS, Zeep!

Yes, of course. You're right Vernon, I should concentrate more upon the machine work. *hrump*,nice bushings Zeep,*snicker*and your filing skills are becoming *chortle* honed. Bwahahaaaaa! I can't stand it anymore! That is just too funny. :big: :big:

BC1

Jim

BC1

Jim

Similar threads

- Replies

- 44

- Views

- 8K

- Replies

- 3

- Views

- 2K