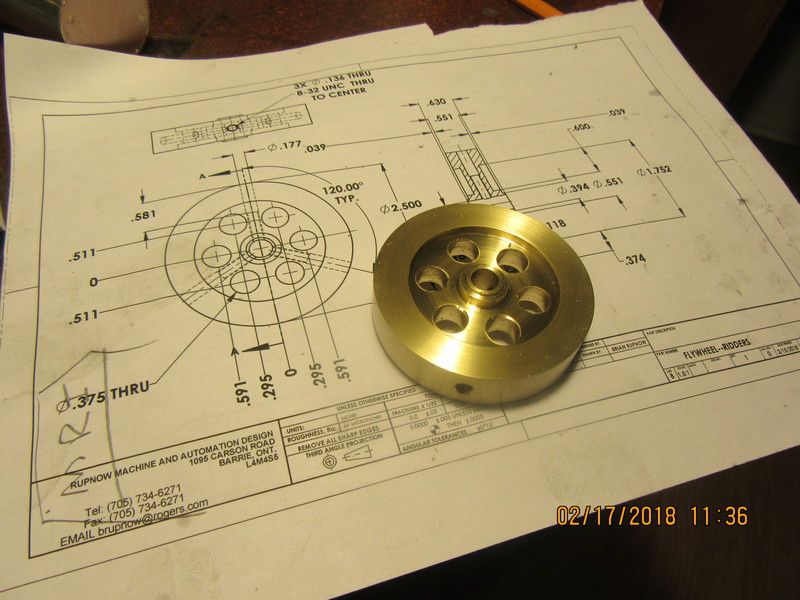

This mornings work yields a pretty little brass flywheel. The best thing about it was that the material was "left over" from the Stirling engine. I try and salvage every little short left over piece of material that I can.

That's pretty.

One of the pains of this hobby is buying metals to work on. I just did an order with Online Metals for parts that will end up in my Duclos engine and really hit a brick wall looking for 3-1/2" aluminum for the flywheel. The smallest piece I could get from Online Metals was $65 - for like an 11" cutoff scrap that I'd need to cut 1" off. I found a guy on eBay that would sell 1" slice for $12 - $7 for the cutoff and $5 for shipping. If I had that brass you had, you'd better believe I'd be using it just like you did.