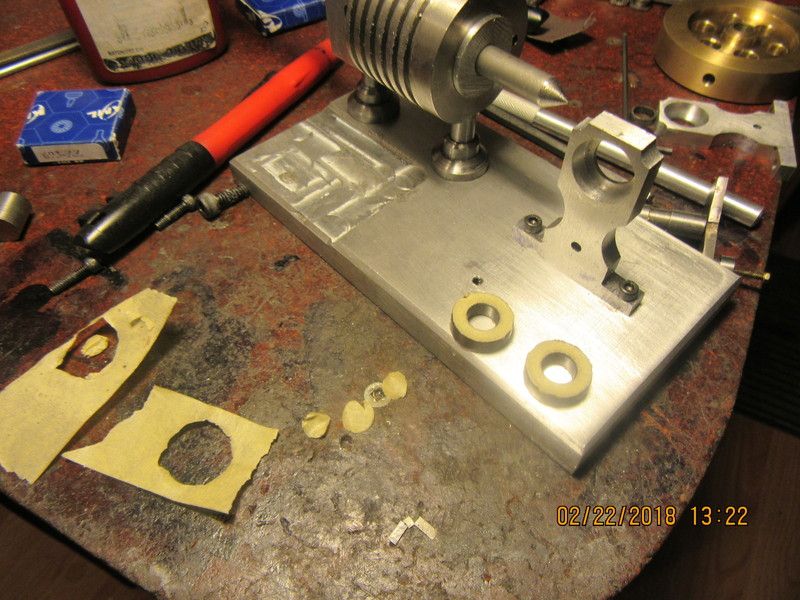

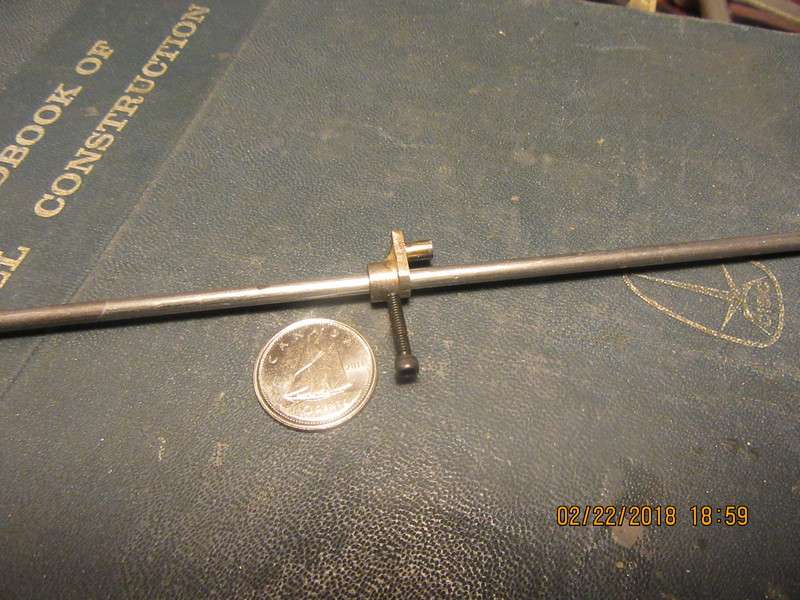

My three bearings came in today. They cost $23.00 total and have seals on them. I'm not going to rush to take the seals out at least until I am set up to do some comparative tests to see how easily they spin. The key issue is that they fit the crankshaft and con rod pin properly. Tomorrow I will put the counterbores in the bearing supports and maybe build a con rod. I am still a bit undecided what material to use for pistons. Jan Ridders drawings indicate that you can use graphite OR cast iron. Nobody in Barrie sells machinable graphite, and I already have some cast iron left over from other projects. I may go with cast iron and if it don't work I can switch to machinable graphite after the fact.