Hi guys,

So I got close to finishing and then life got in the way! Work has been absolutely manic, I'm in the midst of a bunch of home renovations, and my third child arrived safely a couple of weeks ago, so there hasn't been too much spare time to get out to the workshop!

I did manage an hour here and there over the last few months, but all I managed to do was destroy several parts I had already finished :wall:

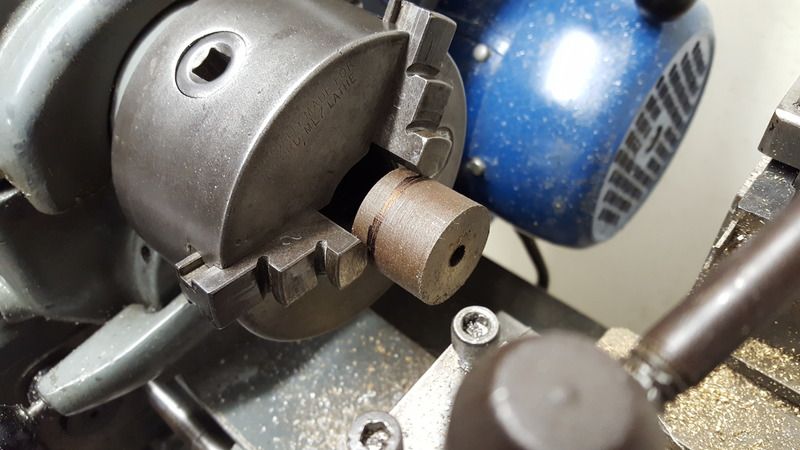

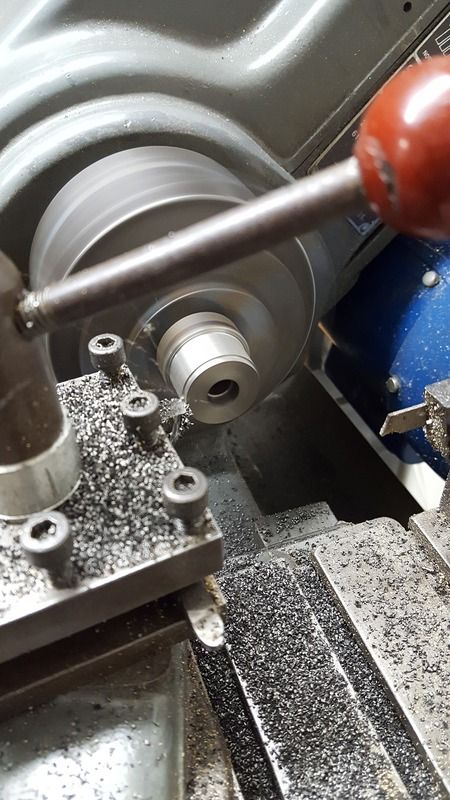

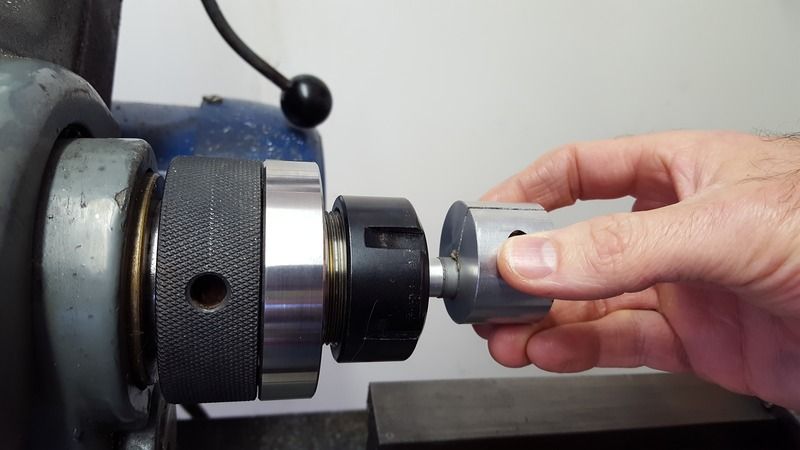

I ordered a ER32 collet chuck and collet set from RDG tools in the UK and after a bit of fiddling got it mounted up to the lathe with about 0.0005" run out which I thought was pretty decent.

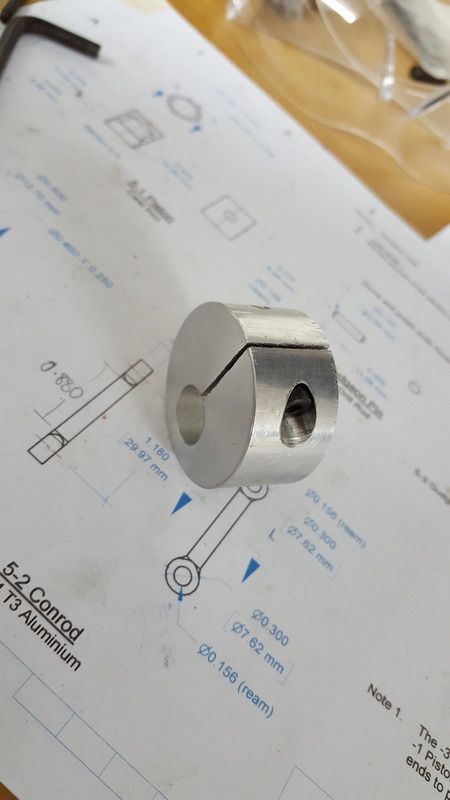

I had previously made a piston lap which I planned to use once I had the collet chuck.

I was a bit reckless with my piston at one point and in my haste I broke the skirt. After a string of bad words and a couple of days of brooding I remade the piston and got to lapping.

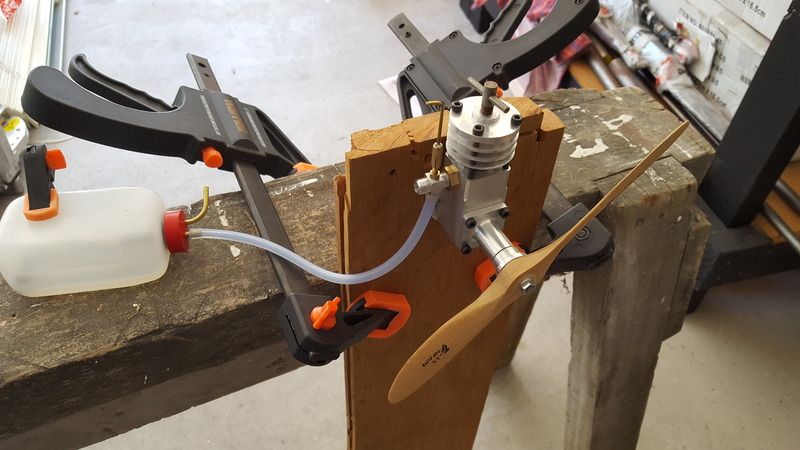

The last photo above is just to show how I held the piston lap by hand while lapping the piston. I ran the lathe at 290rpm and used ~400 grit and then ~800 grit diamond paste to lap the piston. I know people have reservations about the use of diamond paste vs a silicon compound, but I couldn't find the later in NZ and as this engine will likely only run a few times and won't see extended use I figured I would make do.

I'd obviously left way too much extra on the piston and ended up taking nearly 4 thou off by lapping (which took forever!) before the piston just started into the cylinder.

That's about as far as the piston will go at the moment, and I am just about finished making a T-handled tool to use to lap the piston to the cylinder to finish the process. I'm following the process described at the bottom of this page

http://modelengineeringwebsite.com/Super_Tigre_12.html

I also managed to stuff up my spray bar and needle thimble when I tried to solder the needle into the thimble. I had a bit too much clearance in the hole in thimble in my first version and the flux and solder flowed down the needle and very effectively soldered the thimble and spray bar together. :wall:

Lesson learned! I remade the parts and this time made sure the hole in the thimble was a tight slip fit for the 1/16" brass rod I was using for the needle (I was supposed to use piano wire but it was hard to come by and I had the brass rod to hand).

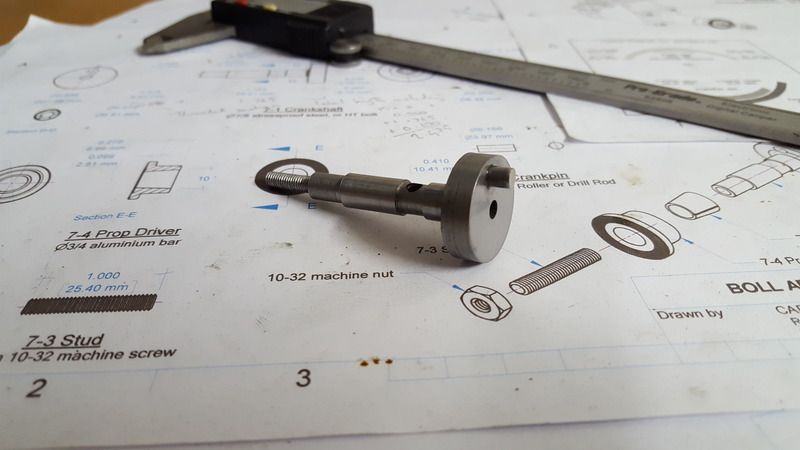

One other little job I had to do was loctite and press the crank pin into the crank.

I've also made and lapped the contra-piston, although it appears I didn't take any photos of that.

So, all that remains now is to finish lapping the piston to the cylinder, and test fit and assemble the engine and I should be close to attempting a first run!

Cheers,

James Fitzsimons