What's next Teflon strips

Teflon strips for what? Teflon is for high boost and requires PM. I didn't have strips on my Chevy and wouldn't waste my time and money unless I was racing for a living. Teflon is for racing not modeling.

What's next Teflon strips

Teflon strips for what? Teflon is for high boost and requires PM. I didn't have strips on my Chevy and wouldn't waste my time and money unless I was racing for a living. Teflon is for racing not modeling.

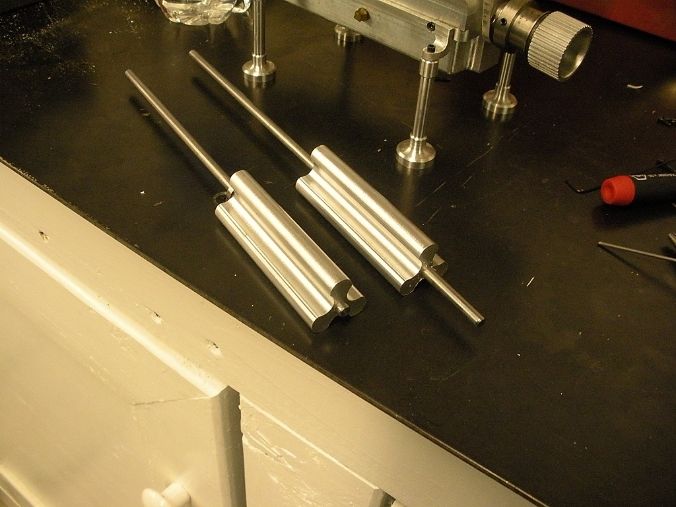

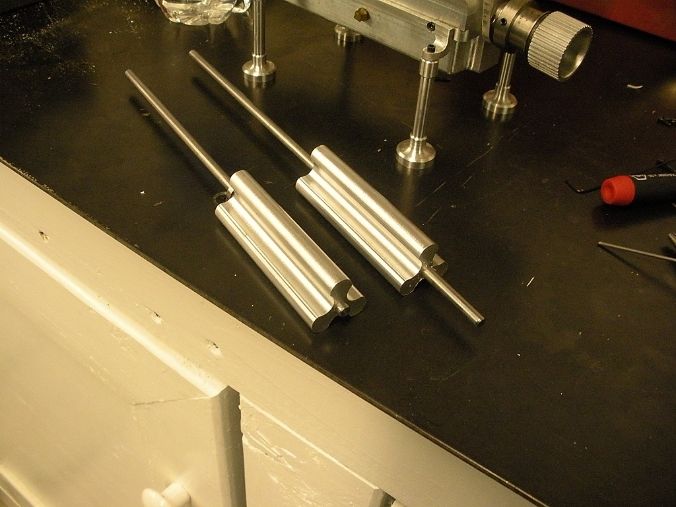

Well! It's official, I now have a pair.

They still need to be deburred and geared together so i can see how they run together. The fit seems very promising. I'm sure there will need to me some fine fitting with some fine grit sand paper.

That is so Cool Steve! I know zip about blowers. Can you elaborate on the how you developed the profile? The lobes & cavities almost look semi-circle arc based, but impossible to tell where I'm standing. You mentioned 0.005" clearance somewhere, is that between the nominal OD of the rotor & ID of the housing? When one sees cogged drive pulleys, is that to time the lobes between one another (ie with clearance) or are they supposed to line contact roll like gear teeth? Any lubrication issues to contend with? Very impressive!

pictures aren't showing up.

He's teasing us

Hahahaa!! Good one!

I just learned that if you right click the box a menu pops up. Click "open image in new tab" and you can view the pix on the photo bucket site. They are not blocked there.

Sorta not really

Your looking at them from your cache, but you can go to your pb site and view the thumbnails and whole album's, but the individual pics wont show. So its close.

Enter your email address to join: