Actually you could probably get a CNC gantry router with a larger capacity than than the XL for the same or less money that could be used for the larger patterns

Then with the money saved buy a 3D resin printer for the smaller parts which would give better surface quality than the XL. Add in some resin wax and you can do the really small stuff with lost wax method

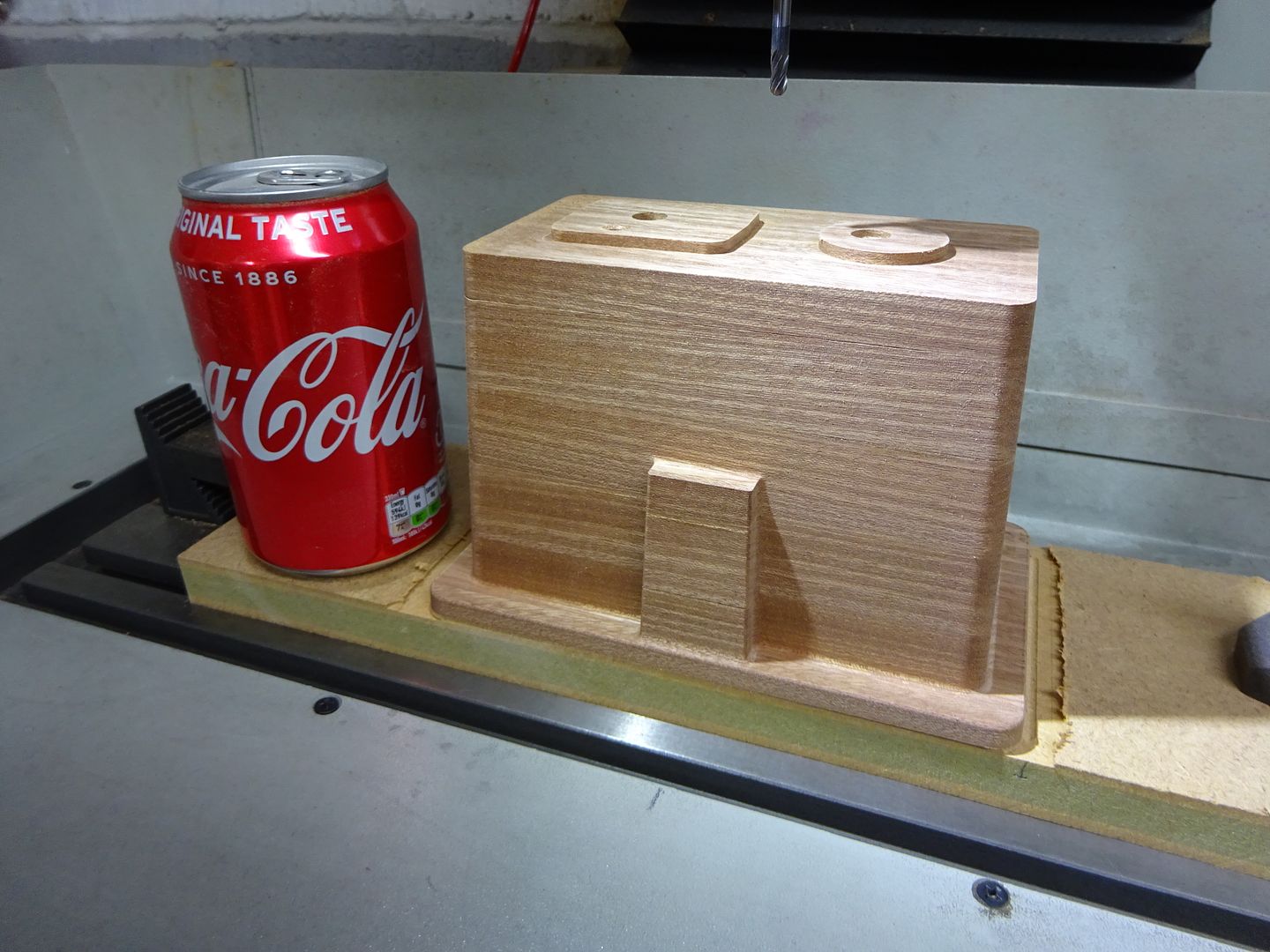

There is much to be said for the CNC router, and the potential surface finishing it could provide.

On the downside a CNC router would create a lot of noise and dust, whereas my XL does not, and I run it in my office.

And some patterns would require gluing wood together, which is an extra step.

And then purchasing carbide bits when they get dull.

No doubt the CNC router is a viable method for pattern making; the question is "Is it right for me ?" (as they say in the pharmaceutical industry).

I have heard stories about the odors from the resin printers, and again that may not work well with my printer being in my office.

And I don't like handling fluids, at least for 3D printing.

I do handle resin for bound sand molds, but it requires wearing a commercial chemical respirator, which is rather a pain.

One person said my video sounds like Darth Vader is making molds; LOL.

Respirators are not fun to wear, especially in the heat.

I have considered the ceramic shell with wax, but that requires some short shelf life slurry, a burnout oven, sometimes a vacuum system, etc.

My hope is that I can use a hybrid lost-PLA method for the small parts, and get something near the quality of ceramic shell/wax without the hassle of that system.

I have seen some impressive lost-PLA results, but have not tried it.

I would use lost-PLA with bound sand, and perhaps do only a partial melt of the PLA, and then remove it manually.

Ceramic mold coat will give surface finish that rivals lost wax.

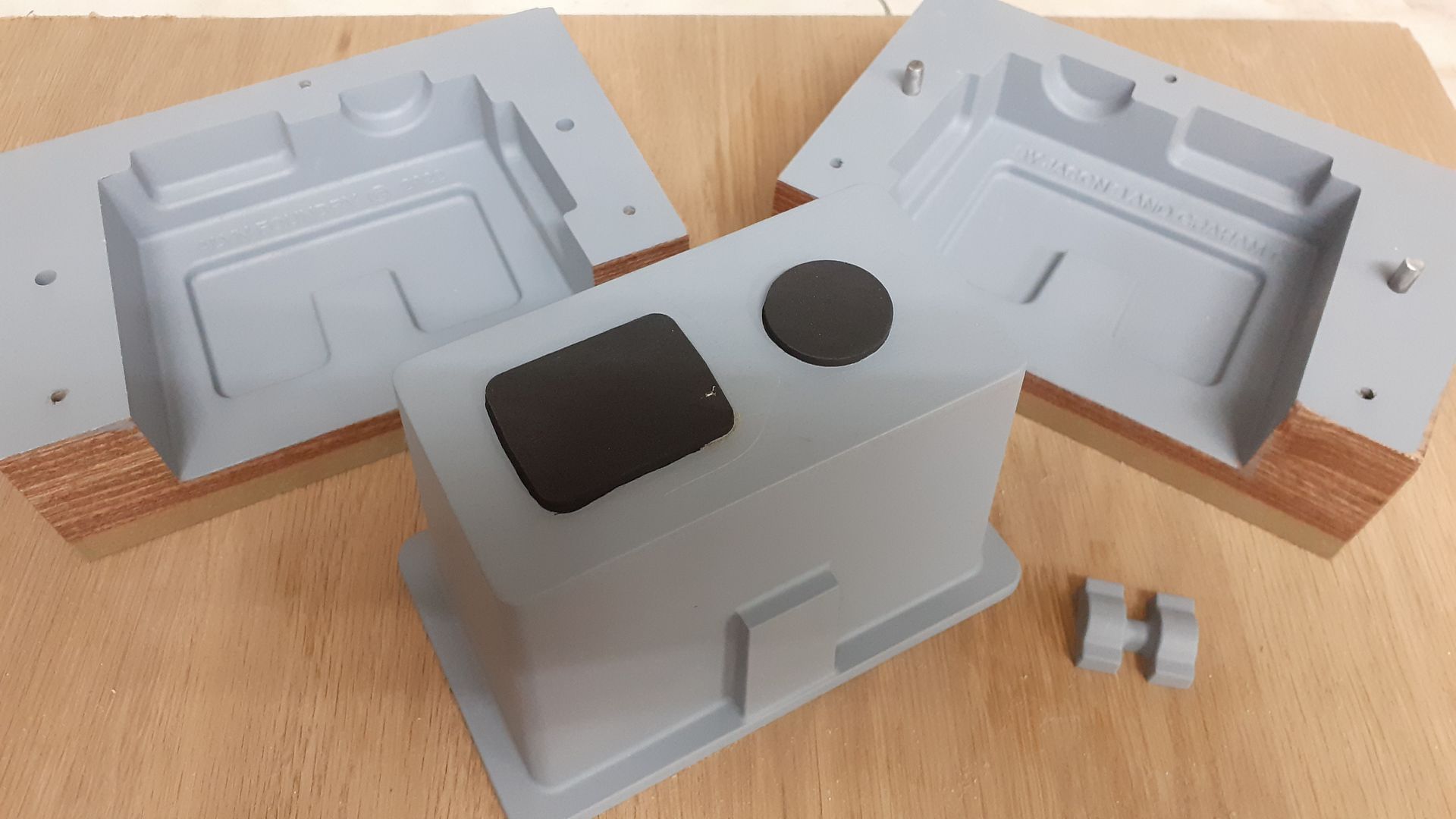

The XL will run quietly by itself unattended, and seems to be very stable as far as not bed-lifting, and recovering easily if the filament breaks, or if the power goes out.

The filament seems to have a long shelf life if it is kept in a sealed bag.

The surface finish on convex surfaces leaves a bit to be desired, but that is something I am experimenting with, to find a quick and easier solution than a manual fill/sand routine.

The polyester auto body filler seems to work pretty well, and is easy to sand with light effort, but still quite a bit of work.

I may try some sort of sputter gun that sprays out filler droplets, but that seems like a long shot, give that the filler starts to set up at some point, and will clog whatever it is being sprayed from.

I have another techinque I want to try with water-based filler on the dog, and perhaps that will be easy.

So I don't see getting away from the XL any time soon, if ever.

I do need to find a faster surface finishing technique.

.