Pat, If you ever want the file for a suitable flywheel just ask, made mine 99mm but easy to scale it up and I could add a pulley

I did tart the base and a few other items up a bit. Not seen the actual article before just the images and part description

Thanks much for the offer.

One day I will get back to that engine.

Can't do it right now for psychological reasons.

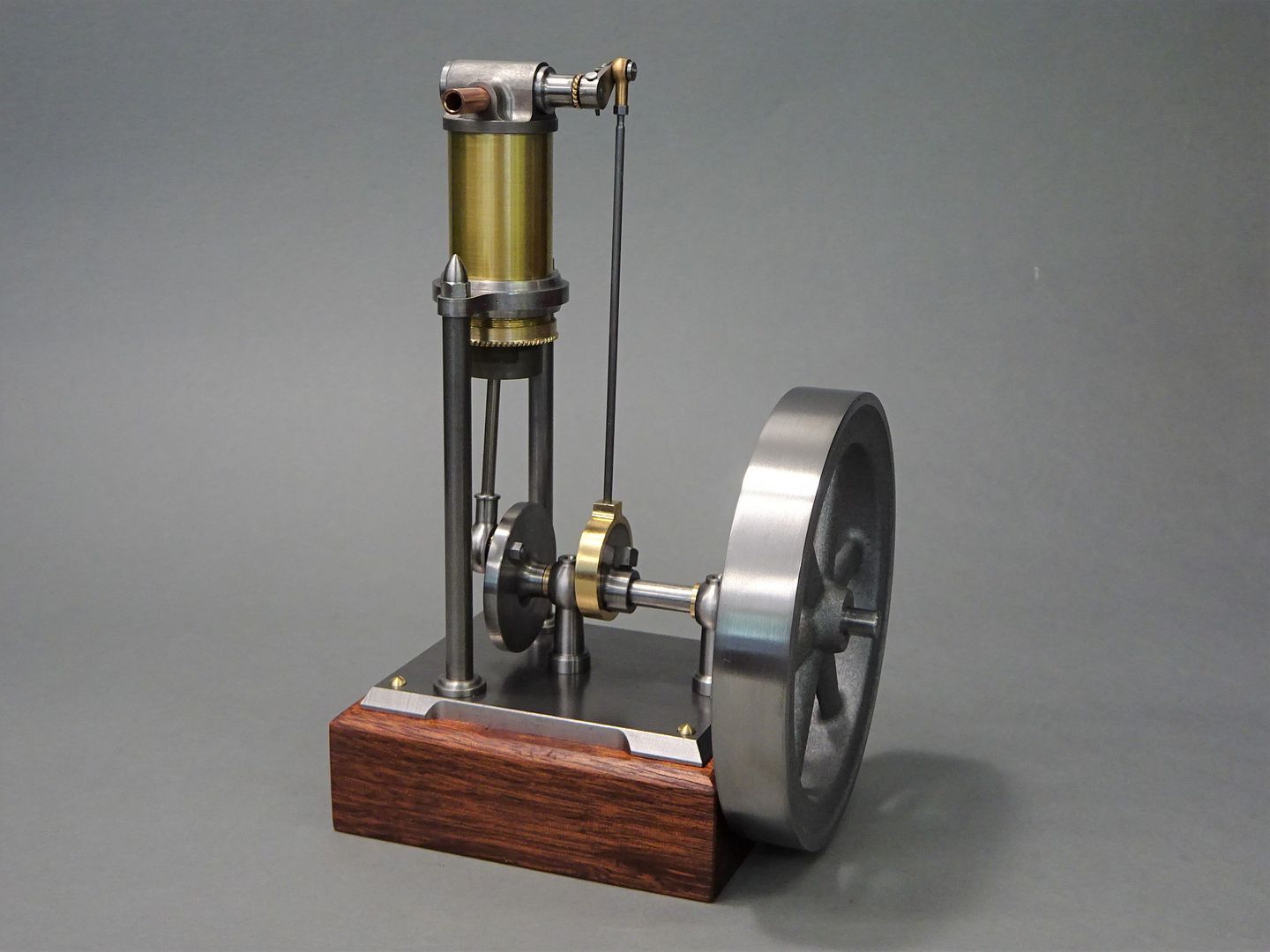

That is a beautiful Scientic American build for sure !

.