putputman

Senior Member

- Joined

- Nov 22, 2008

- Messages

- 600

- Reaction score

- 55

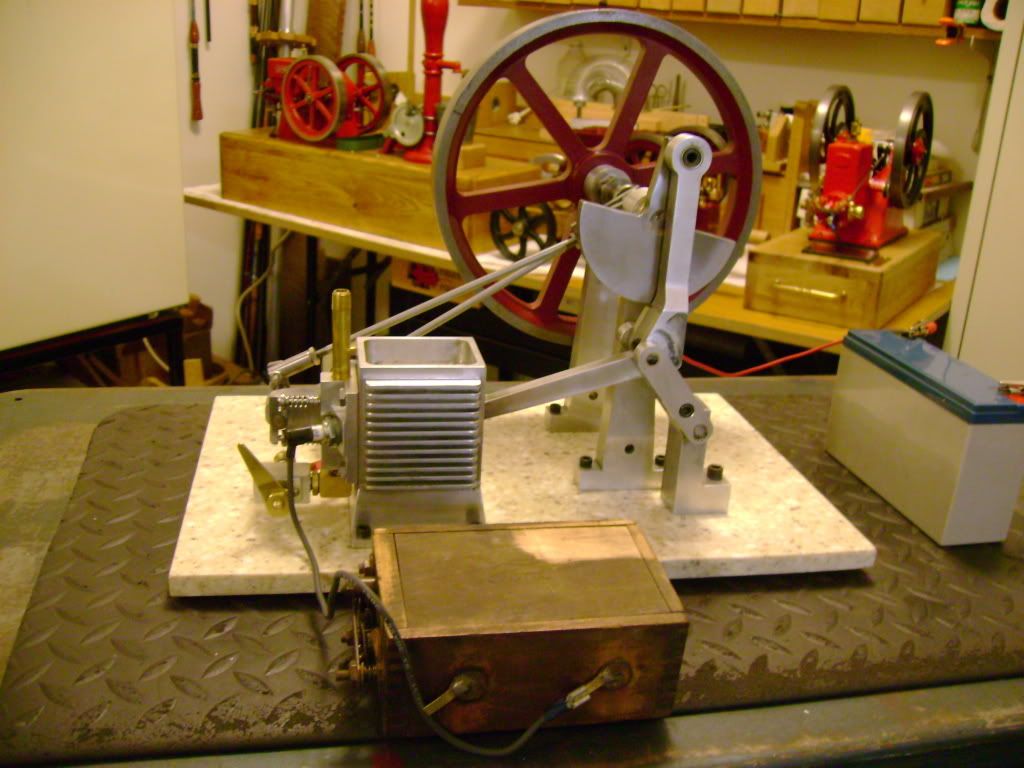

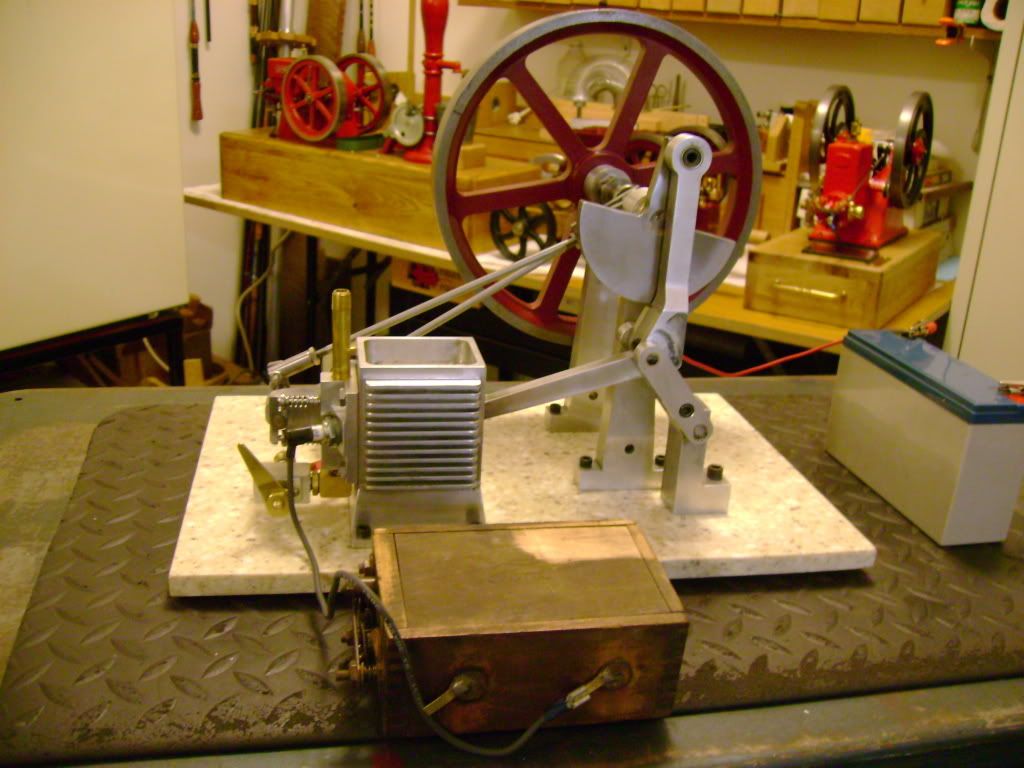

I finally test run my Gingerly Atkinson Cycle Engine. I started it last fall when I started the New Holland engine. Each time I got to the point I had to walk away from the New Holland, I would work on the Atkinson, Elmer's Tiny, Chuck Fellows Hit & Miss, Chuck Fellows John Deere, and Brian's Slinky.

I still have some "bling" to do on this engine. Once I get a suitable ignition system I will complete the base for it and may paint it the aluminum.

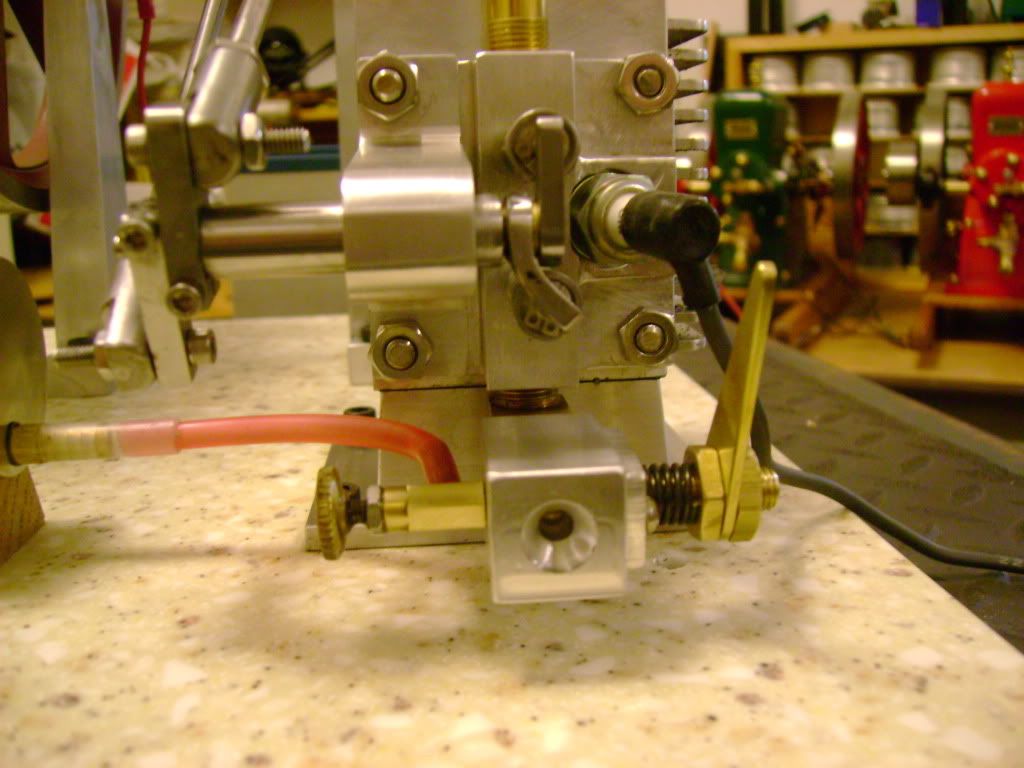

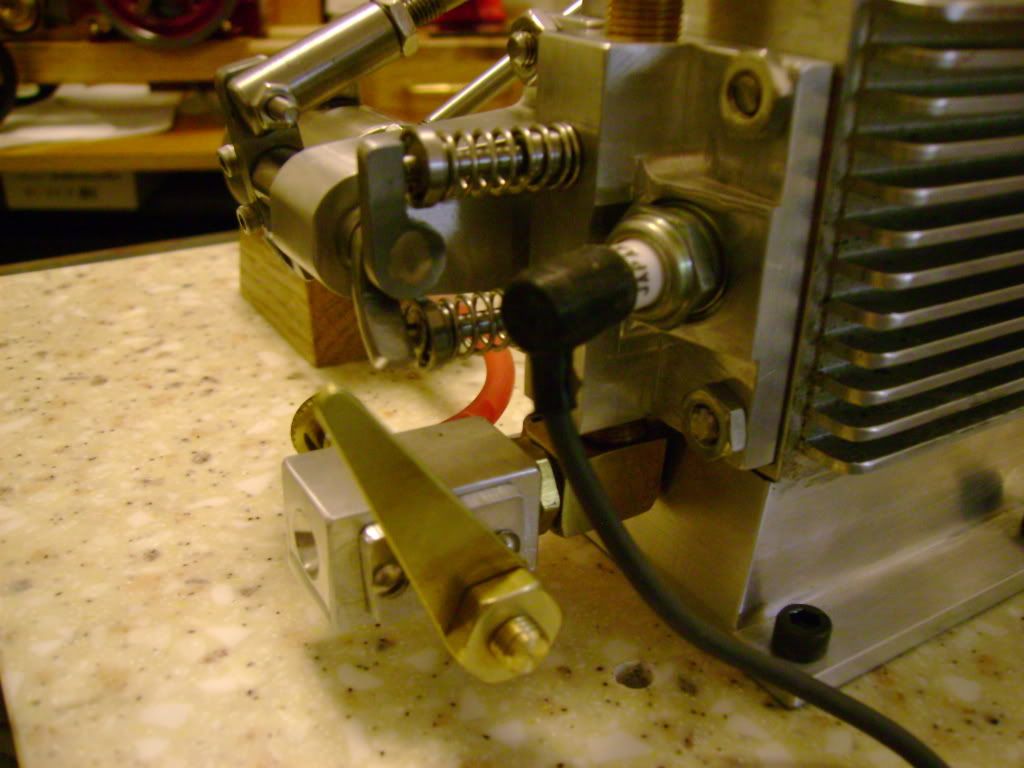

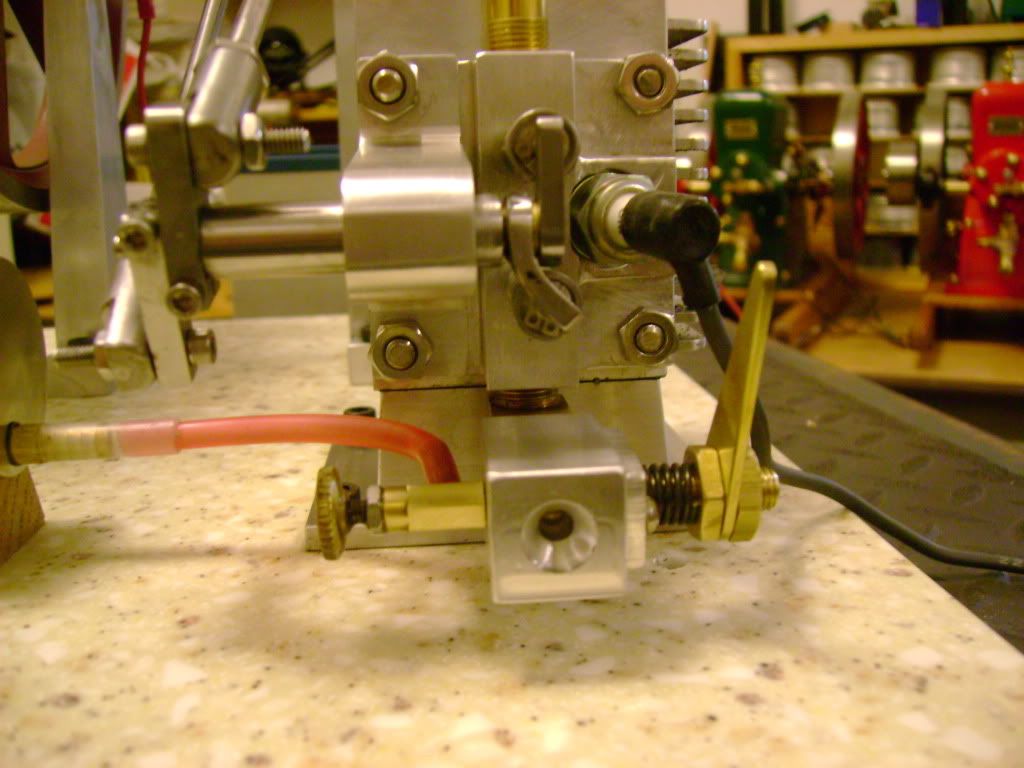

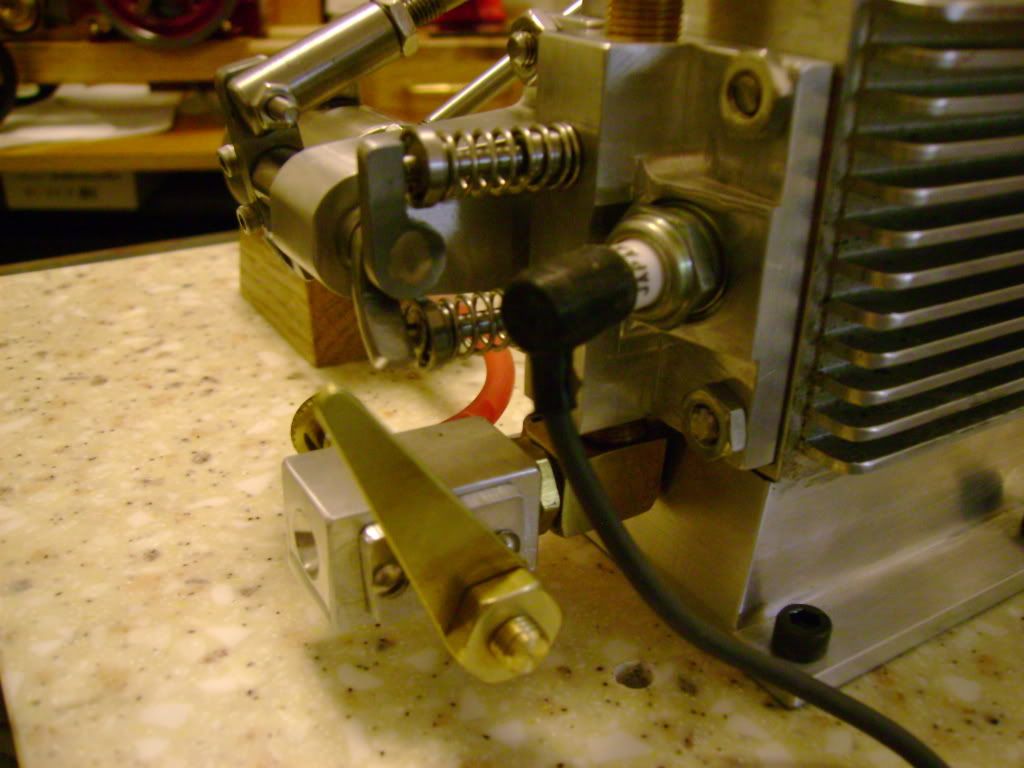

I had to modify the carburetor. I couldn't get the Gingerly design to run.

This is the valve system.

This might be a good I.C. engine for people that want to avoid making or buying gears. It get four cycles by using linkages instead of gears.

I still have some "bling" to do on this engine. Once I get a suitable ignition system I will complete the base for it and may paint it the aluminum.

I had to modify the carburetor. I couldn't get the Gingerly design to run.

This is the valve system.

This might be a good I.C. engine for people that want to avoid making or buying gears. It get four cycles by using linkages instead of gears.