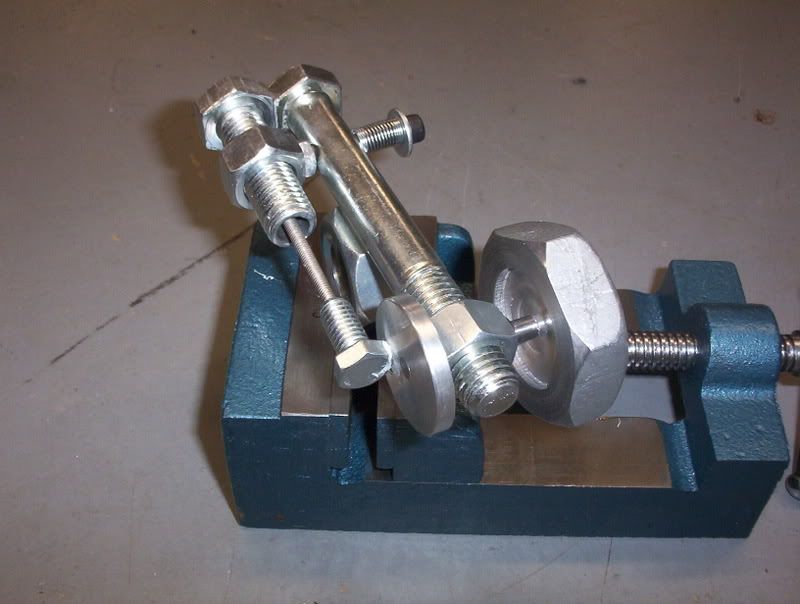

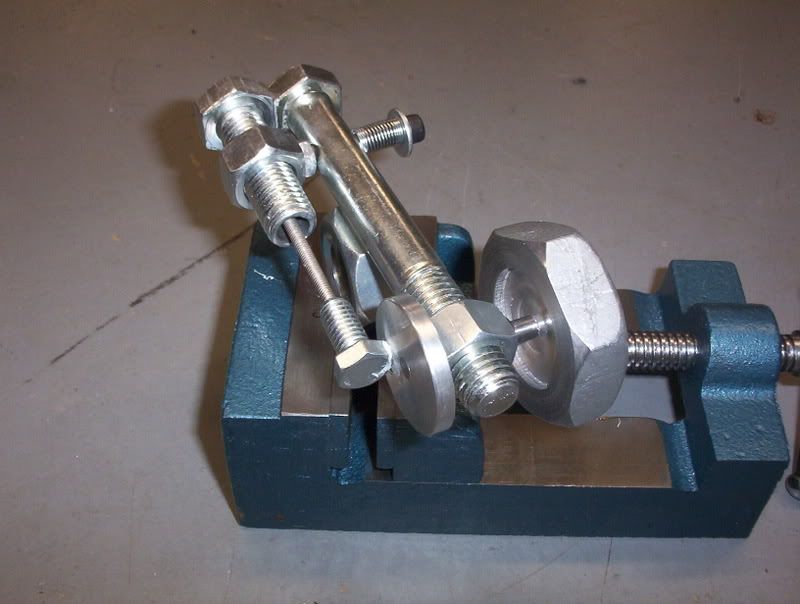

Well, after seeing the engine that Kactiguy built, I decided that I would build one myself. After a little bout with some self induced stupidity : , here is what I cobbled up.

, here is what I cobbled up.

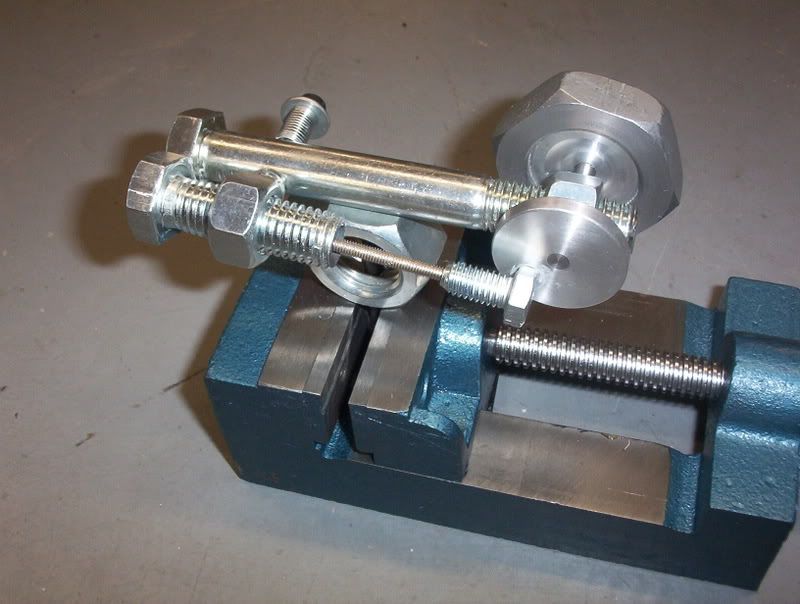

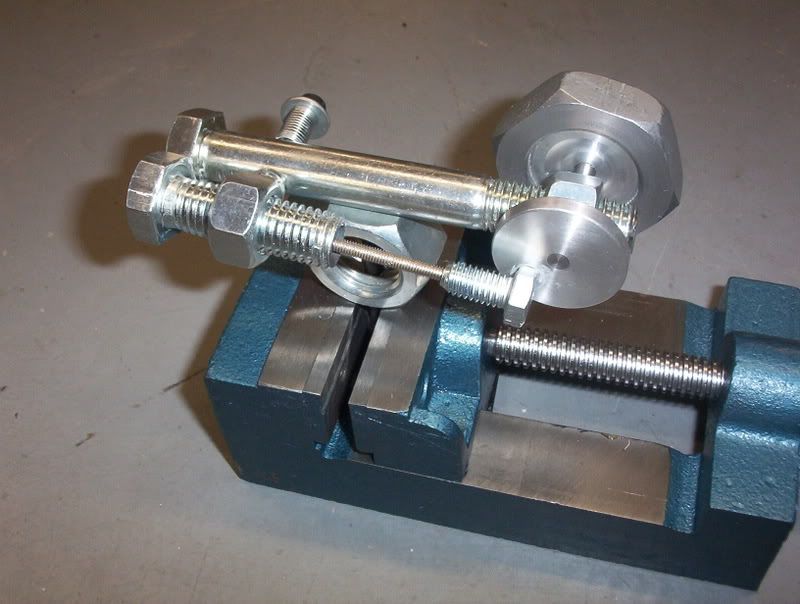

It is a pretty good runner. Unfortunately, I don't have a video of it, yet. When I get the base done, I will post additional pictures and a video as well.

I haven't finished the base for the little guy yet, but will mount it on a piece of stained oak. It certainly was a fun easy build.

It is a pretty good runner. Unfortunately, I don't have a video of it, yet. When I get the base done, I will post additional pictures and a video as well.

I haven't finished the base for the little guy yet, but will mount it on a piece of stained oak. It certainly was a fun easy build.