deere_x475guy

Well-Known Member

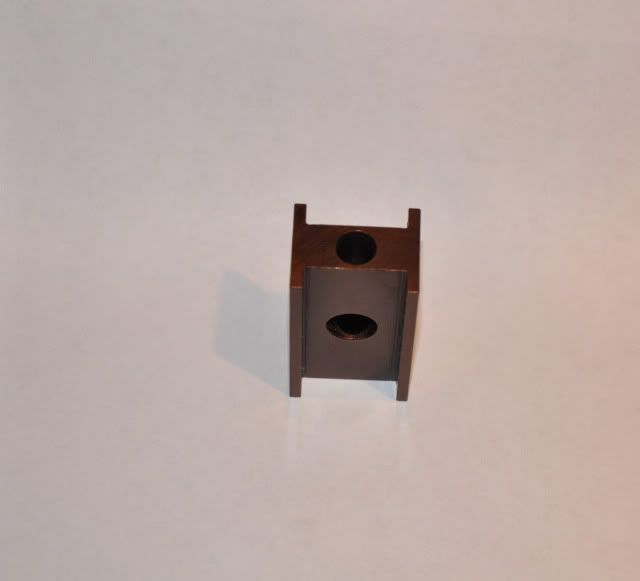

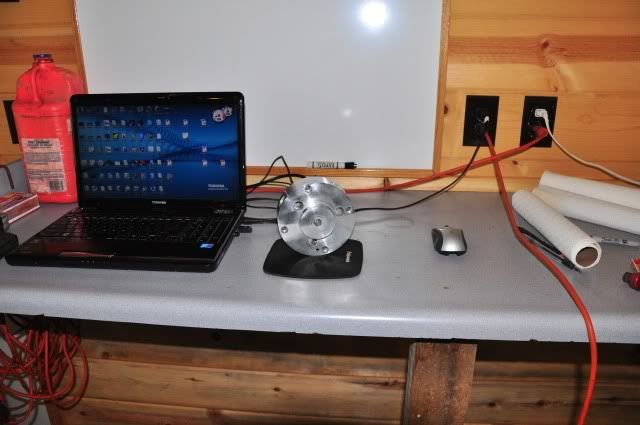

Today instead of going the the flywheels on the Siamese Twin I decided to try a part that I will most likely do more of and it is about the biggest part I plan on doing for now. This is just scrape now...many times over prototype.

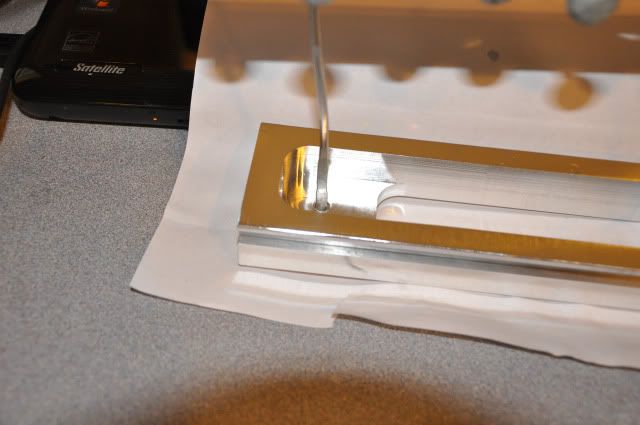

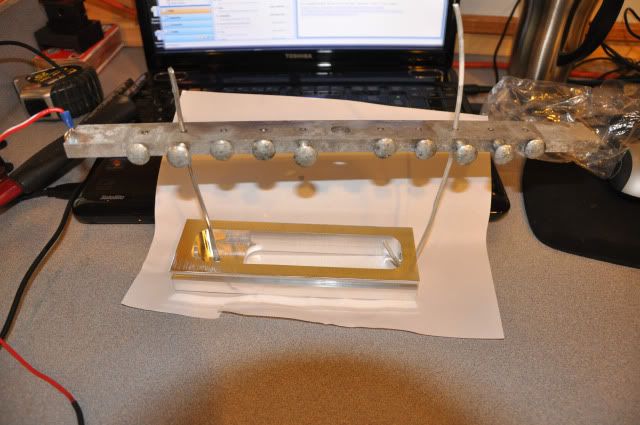

I put it about 30 minutes ago...it was a bear trying to bring the acid bath from room temp of 84 degrees to 70 but I finally got it there. More pics to come..

I put it about 30 minutes ago...it was a bear trying to bring the acid bath from room temp of 84 degrees to 70 but I finally got it there. More pics to come..