mklotz

Well-Known Member

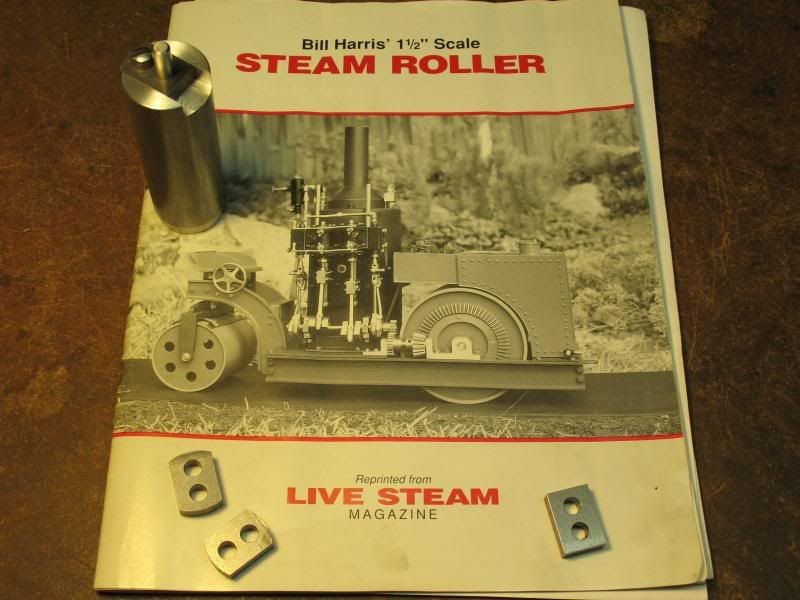

I've decided to take a shot at building Bill Harris' steam roller. Since this is a big project and contains details outside my skill set, I may never finish it but, what the heck, it's always good to think big.

Since it may never be completed, I decided to start by building the engine. That way, if the rest never gets finished, I'll at least have a working engine out of the deal.

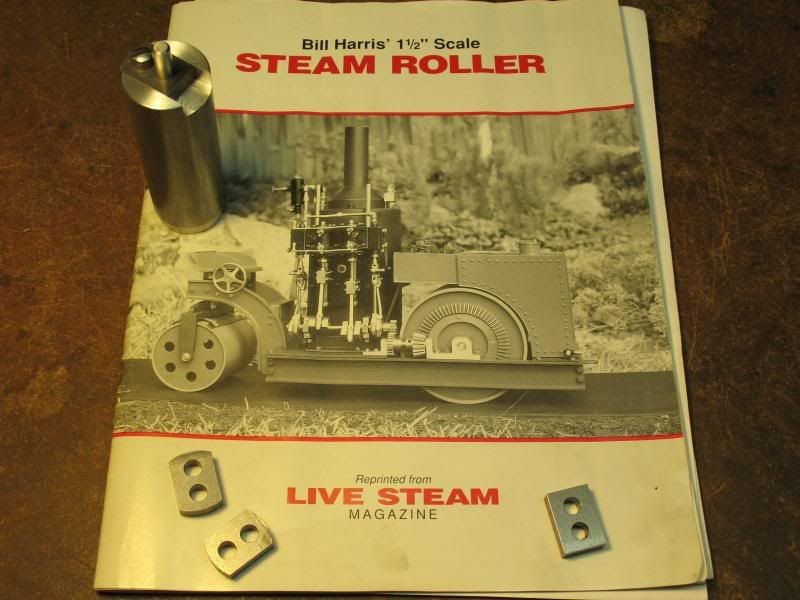

The engine has a built-up crankshaft that requires four plates to achieve the orthogonal offsets. These are roughed out as rectangular blocks of 1/4" steel, drilled for the drill rod that will form the round bits, and then need their ends rounded to a 5/8" radius in order to look "kewl".

I took a slug of aluminum left over from another job of this type (the equivalent pieces on the Poppin engine) and drilled and reamed it for a 1/4" locating pin. After milling a slot the width of the parts, I drilled and tapped for a 10-32 screw to lock the part in place after it is slid over the pin.

The slug is then chucked and the radius turned. Flip part and repeat. Total time to do all four parts was about ten minutes.

Since it may never be completed, I decided to start by building the engine. That way, if the rest never gets finished, I'll at least have a working engine out of the deal.

The engine has a built-up crankshaft that requires four plates to achieve the orthogonal offsets. These are roughed out as rectangular blocks of 1/4" steel, drilled for the drill rod that will form the round bits, and then need their ends rounded to a 5/8" radius in order to look "kewl".

I took a slug of aluminum left over from another job of this type (the equivalent pieces on the Poppin engine) and drilled and reamed it for a 1/4" locating pin. After milling a slot the width of the parts, I drilled and tapped for a 10-32 screw to lock the part in place after it is slid over the pin.

The slug is then chucked and the radius turned. Flip part and repeat. Total time to do all four parts was about ten minutes.