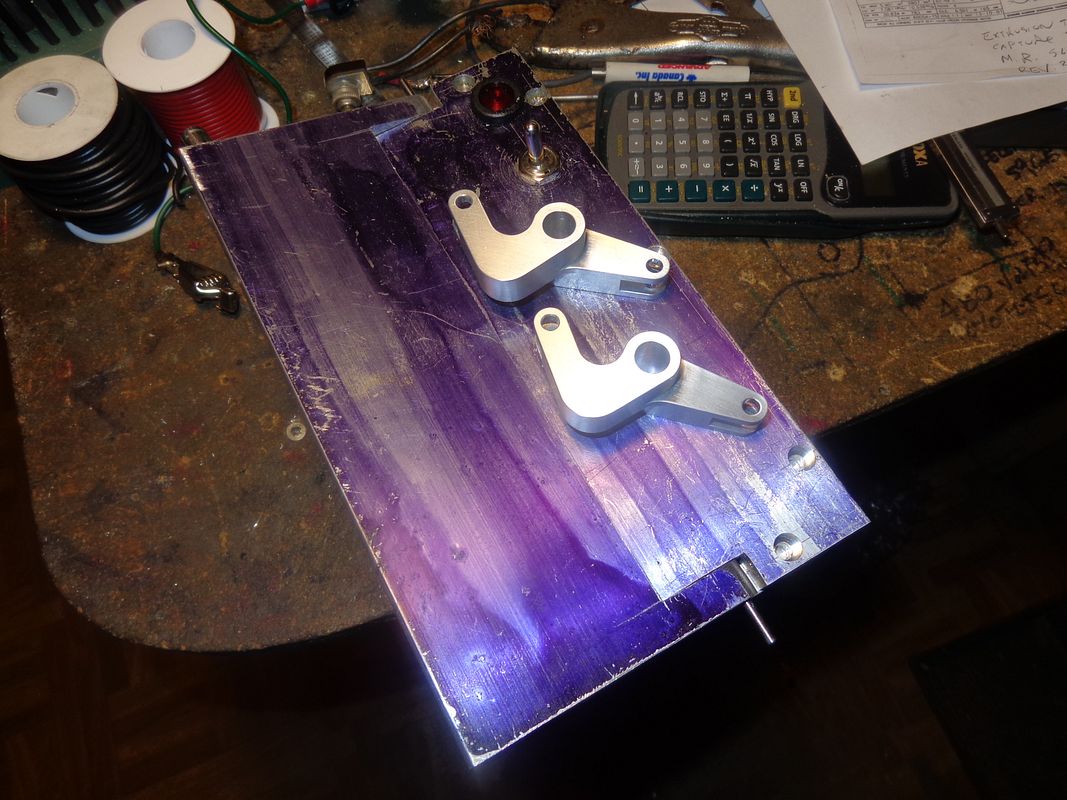

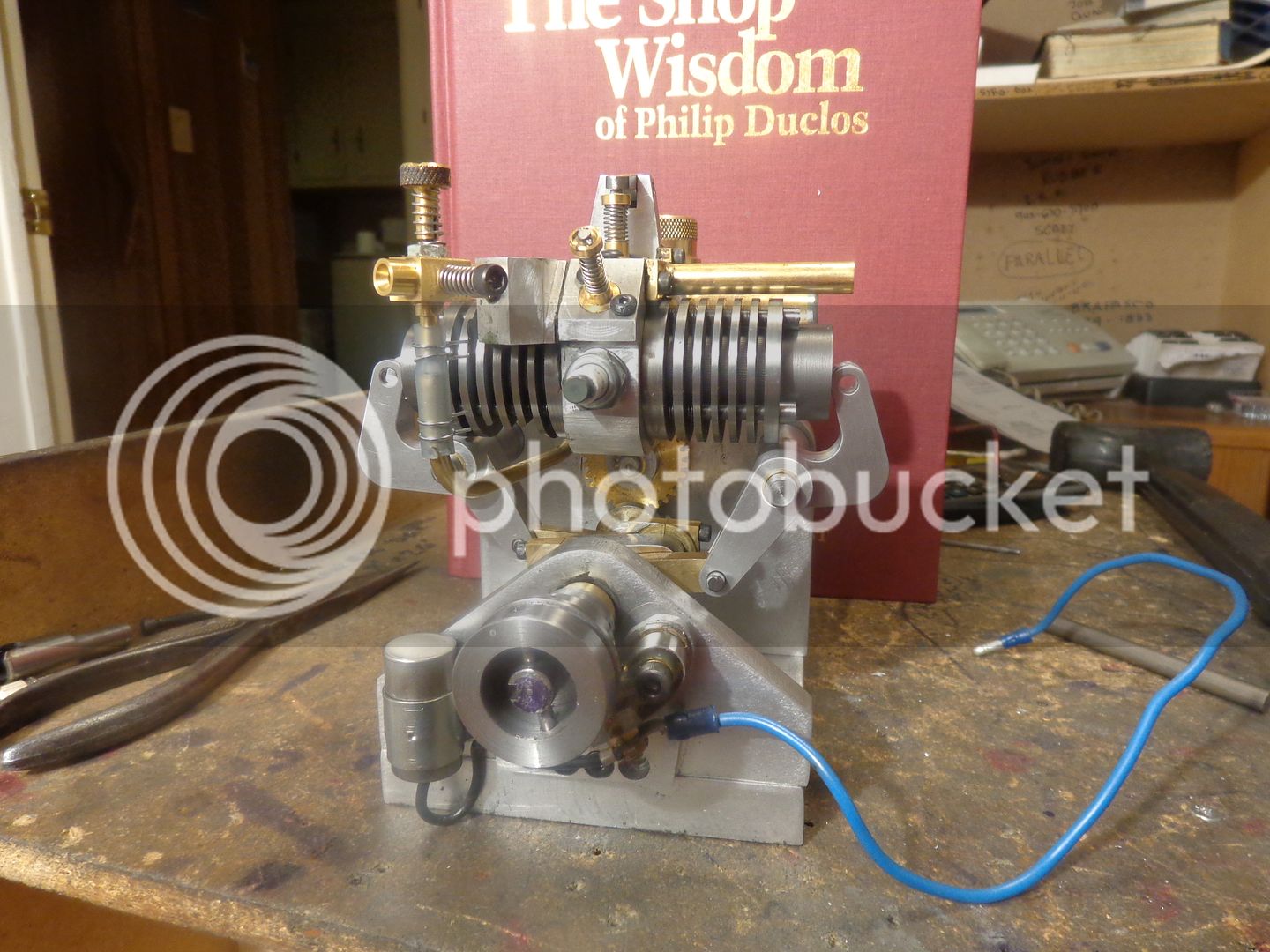

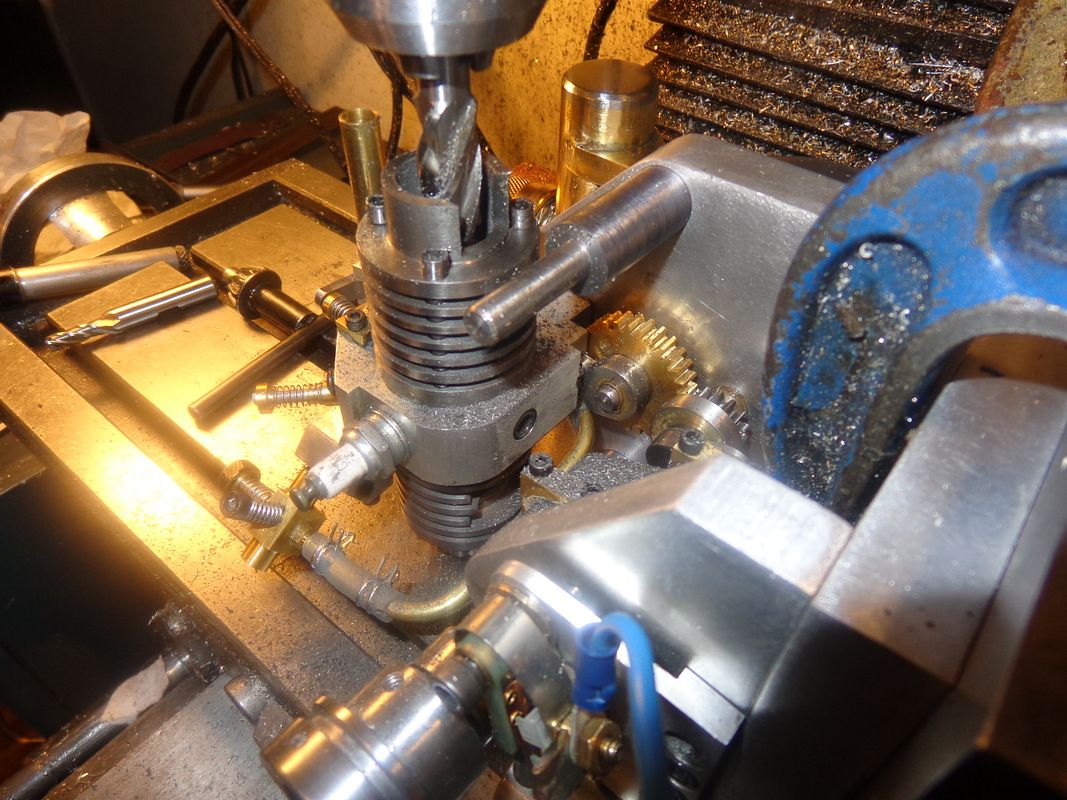

So---I don't think I can be any readier than I am now. The valve timing is set. I do that by loosening off the grub screws in the crankshaft gear so that I can rotate it by hand without the crankshaft moving. Then I turn the crankshaft over in the direction I want the engine to rotate until the pistons are about 1/8" from being at bottom dead center. Then I rotate the crankshaft gear in the same direction with my fingers (the camshaft gear will rotate in the opposite direction) until the lobe on the cam is just at the point where if it went any farther it would start to lift the exhaust valve. Then I lock down the crankshaft gear grubscrews, and that's all there is to valve timing.--The ignition timing is set. I do that by loosening off the grub screw in the ignition cam so the cam rotates free of the crankshaft. I keep turning the crankshaft in the direction I want the engine to run until the piston is about 1/8" before top dead center. Then I rotate the ignition cam in the same direction . If you have seen the drawing of this engines ignition cam, you will see that it is perfectly round with a flat machined on one side. Whenever the rubbing block on the cam is riding up on the main diameter, the points are open. When the leading edge of the flat gets to the rubbing block on the points, they will close. The stay closed until the trailing edge of the flat spot lifts the points open again.--And that (the points opening) is what collapses the primary "field" in the coil and induces a high tension spark in the secondary windings of the coil. I set the position of the cam so the points begin to open at about 1/8" before the pistons reaches top dead center, and lock down the ignition cam grubscrew. ----I have filled my new fuel tank with a 40:1 mix of Coleman fuel and 2 cycle engine oil. This will lubricate the pistons and the cylinders and the Viton O-rings. I have the engine setting on top of 3 sheets of white printer paper, so if there are any leaks in my fuel system I will see tomorrow morning. I have opened the needle valve on Chucks carburetor 3/4 of a turn, and opened the throttle screw one full turn from the fully closed position. The valve lash is set so that when the pushrod is not riding up on the cam there is about .015" free play between the top of the valve and the rocker arm. All that remains to do is hook up my coil and battery, cross my fingers, say a short prayer to the God of small engines, and crank it up. Cross your fingers for me!!!---Brian