You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1:8 scale 3HP buffalo twin marine engine

- Thread starter mikemott

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

mikemott

Well-Known Member

- Joined

- Oct 24, 2014

- Messages

- 53

- Reaction score

- 67

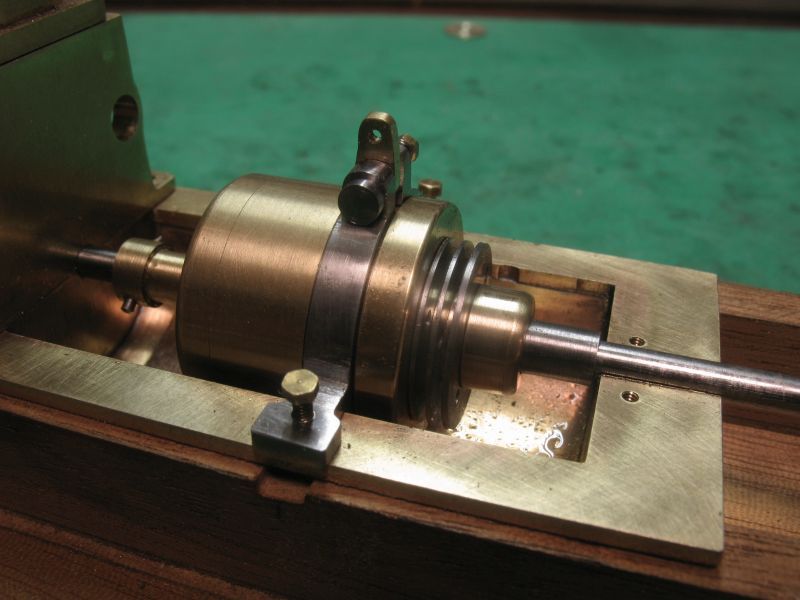

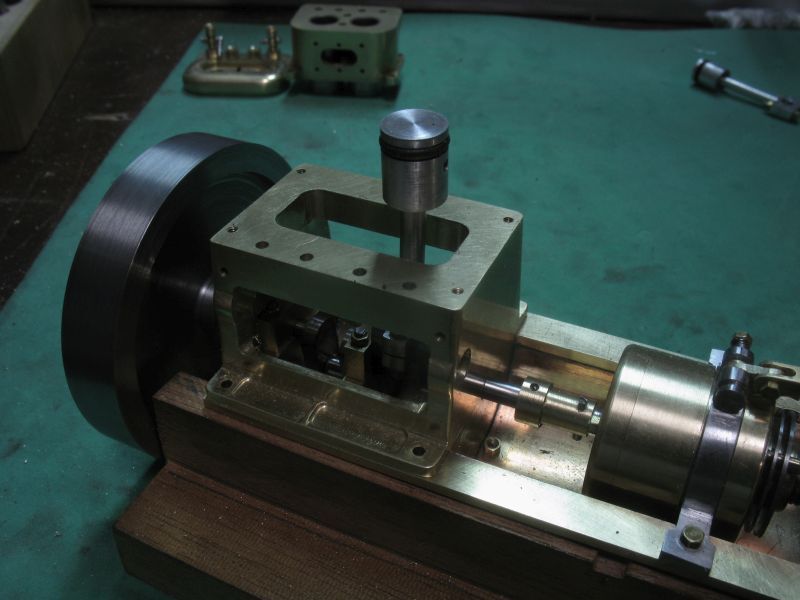

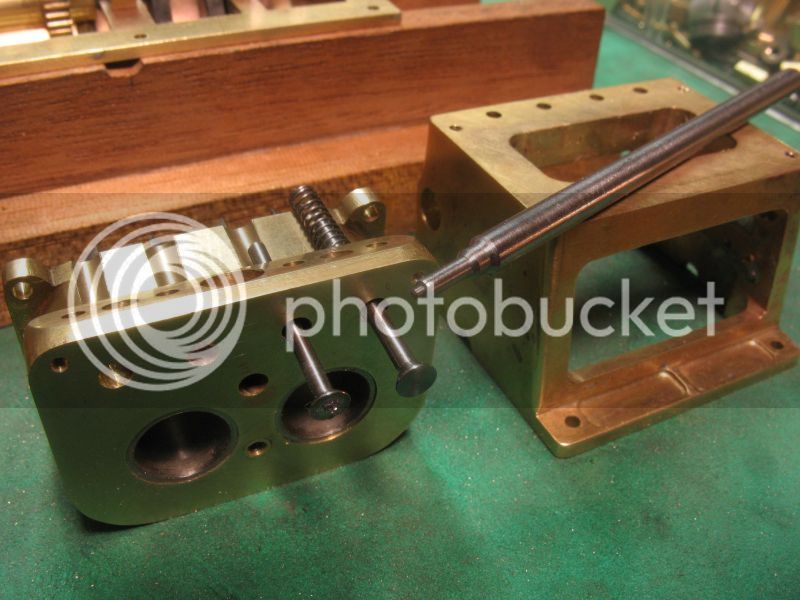

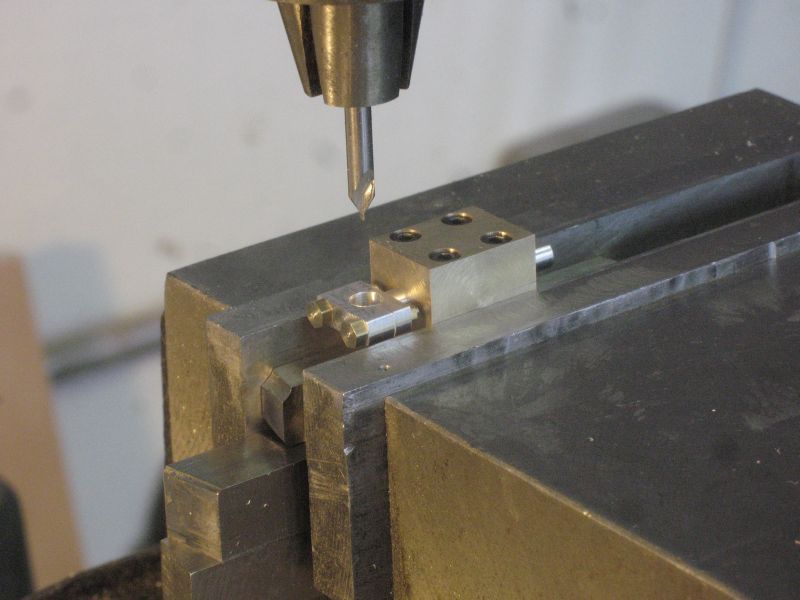

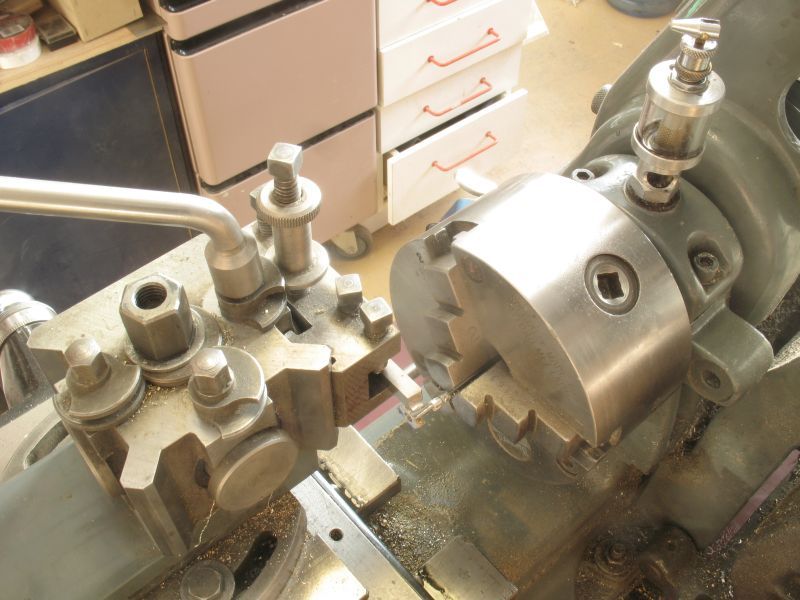

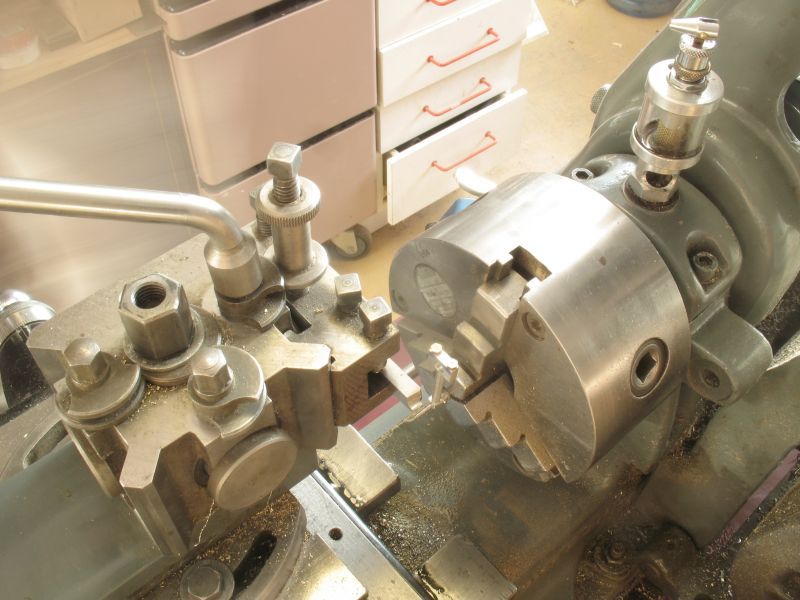

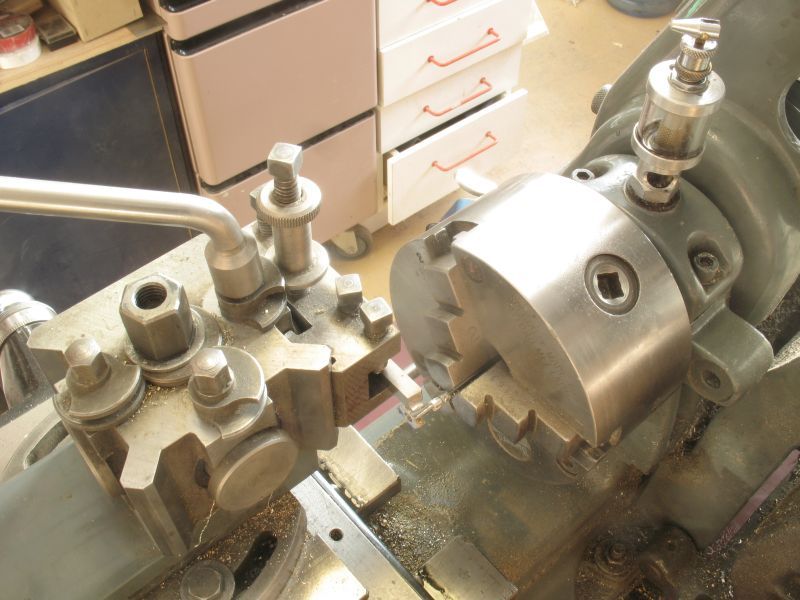

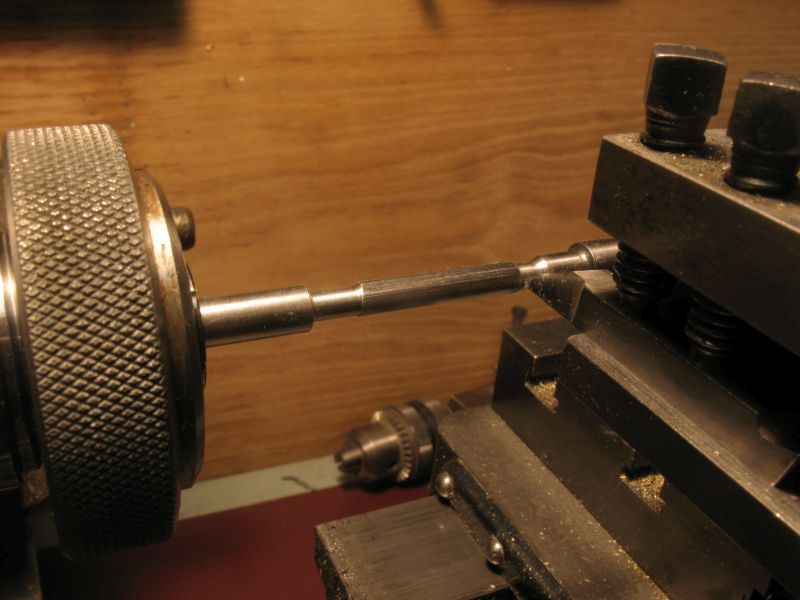

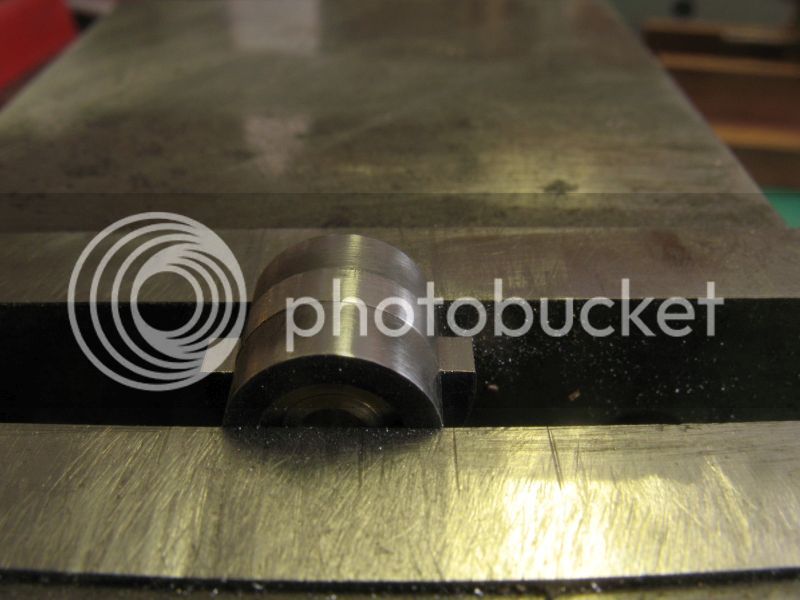

A bit more progress on the con rods A small holding fixture to work on them was needed because I do not have an indexing fixture for the chuck.

I marked the area that still needs to be removed, the bolts are temporary just for the machining.

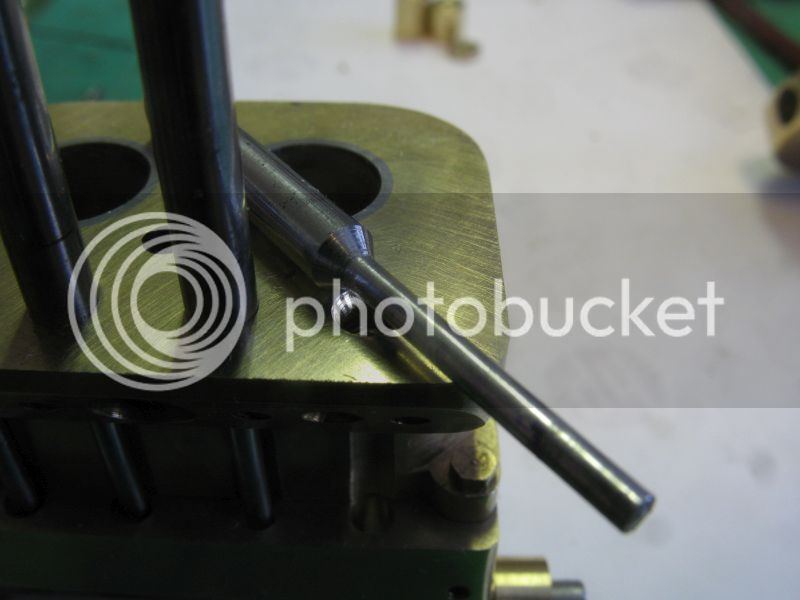

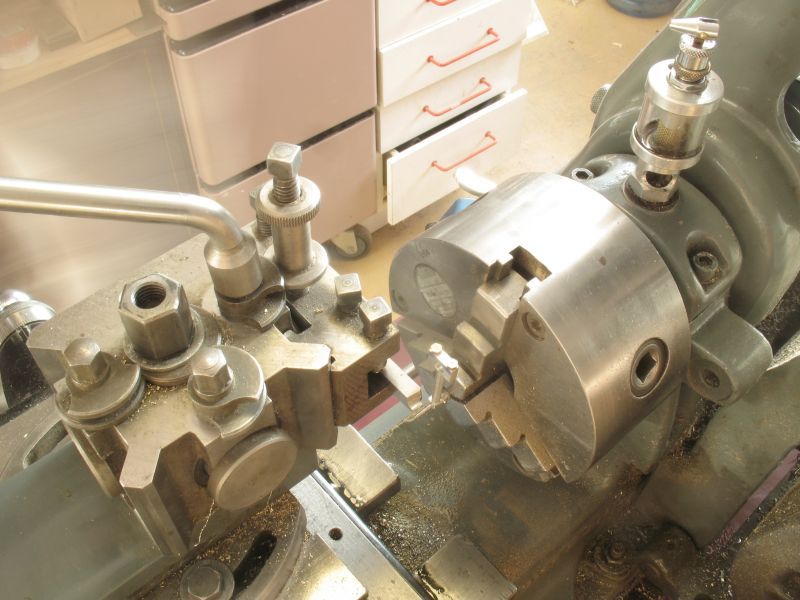

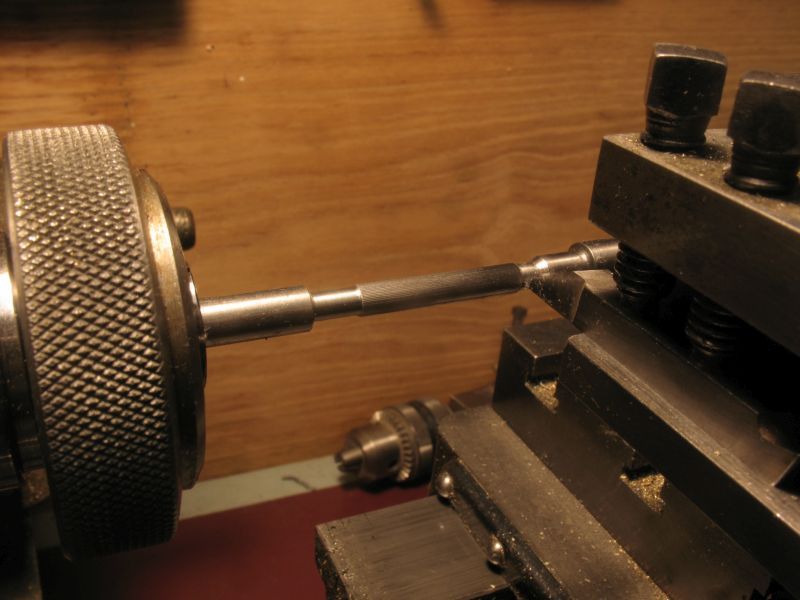

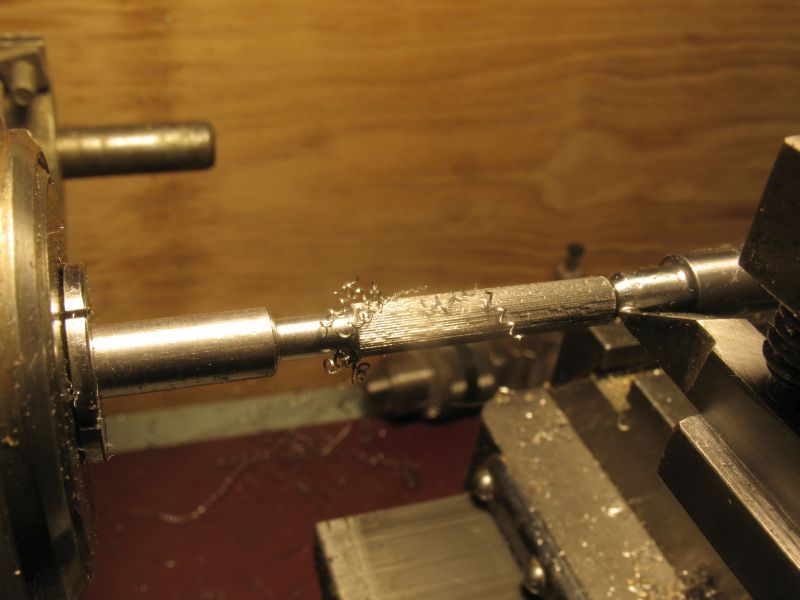

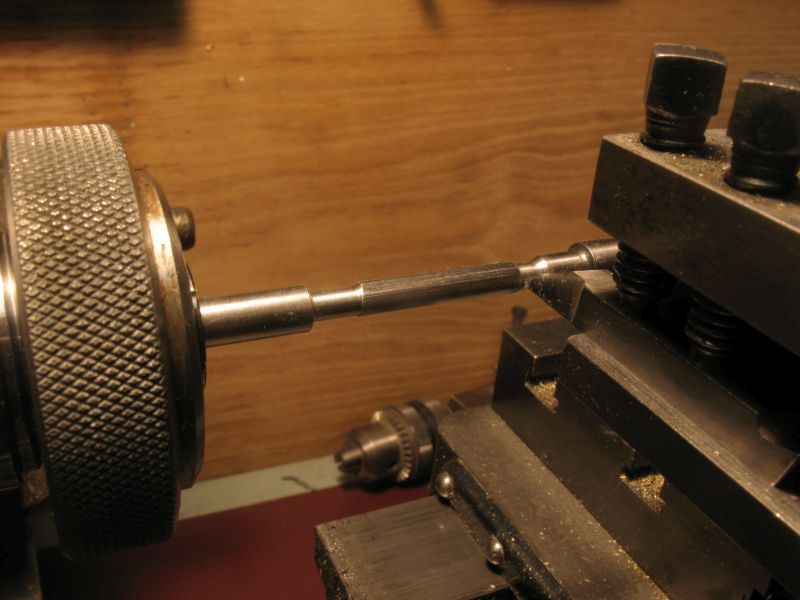

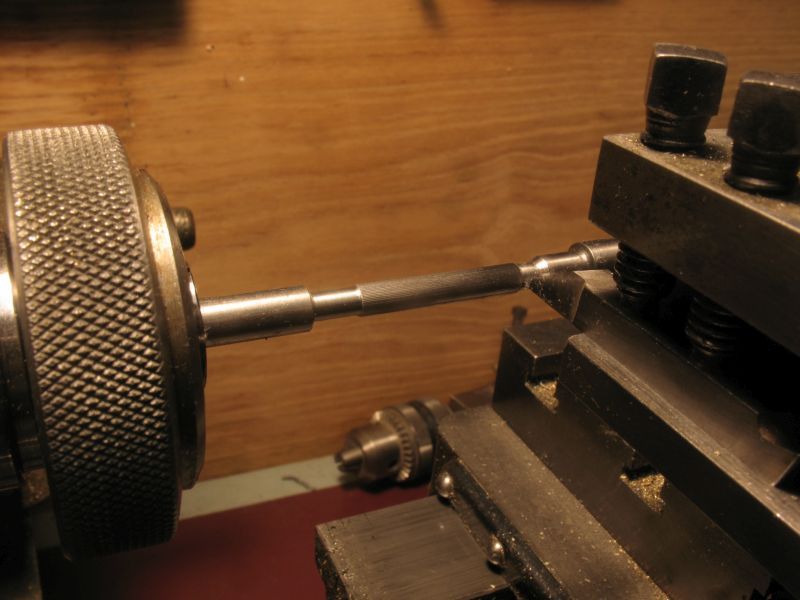

I used the lathe as a shaper for working the top end of the con rods, they are held on a tight slide fit pin, and I took .002" cuts with a round nosed bit held sideways in the tool post, I have cut gears this way in the past. it is slow but works well.

The result after the initial shaping.

then a bit of work with the rat tail file

after the brush with a hand held brass wire brush, it is ready to mount.

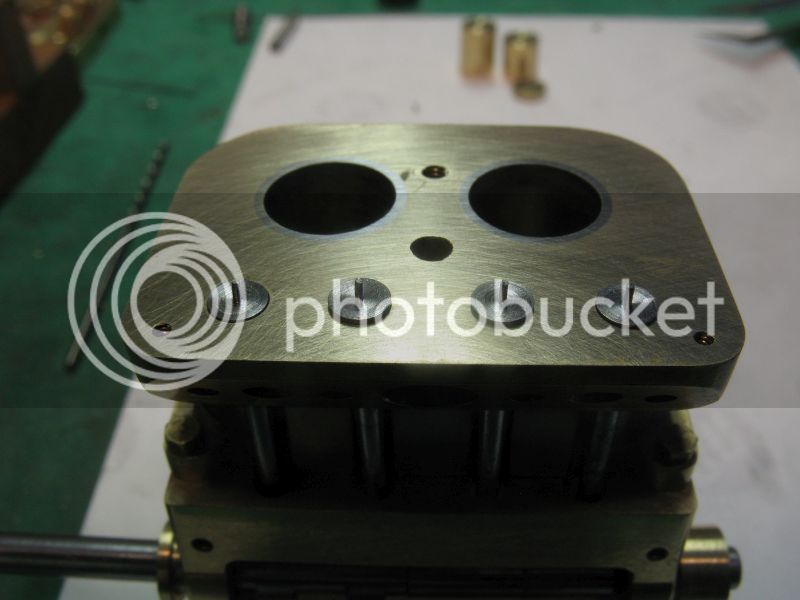

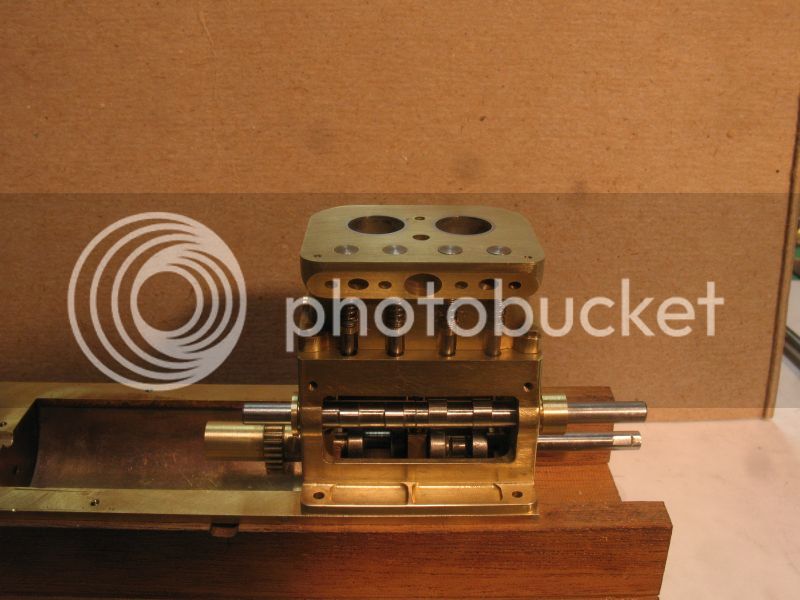

The con rods are now attached

Mike

I marked the area that still needs to be removed, the bolts are temporary just for the machining.

I used the lathe as a shaper for working the top end of the con rods, they are held on a tight slide fit pin, and I took .002" cuts with a round nosed bit held sideways in the tool post, I have cut gears this way in the past. it is slow but works well.

The result after the initial shaping.

then a bit of work with the rat tail file

after the brush with a hand held brass wire brush, it is ready to mount.

The con rods are now attached

Mike

mikemott

Well-Known Member

- Joined

- Oct 24, 2014

- Messages

- 53

- Reaction score

- 67

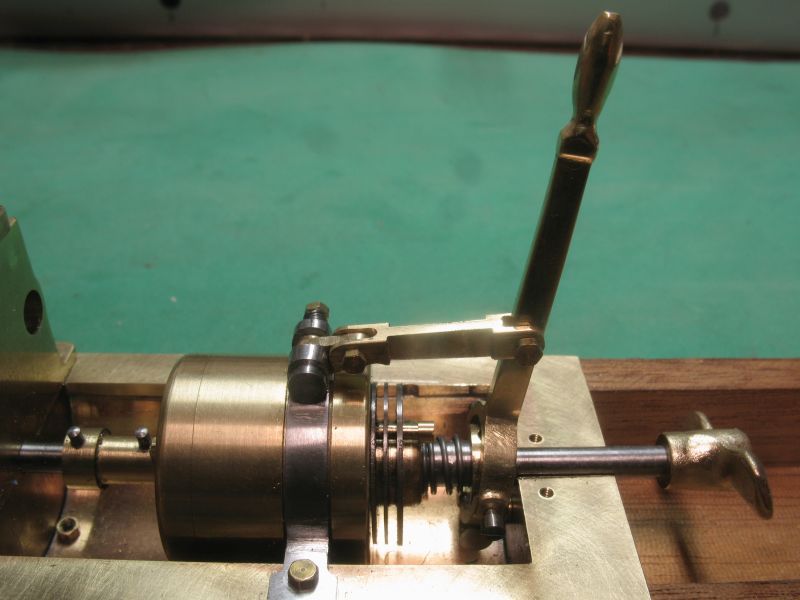

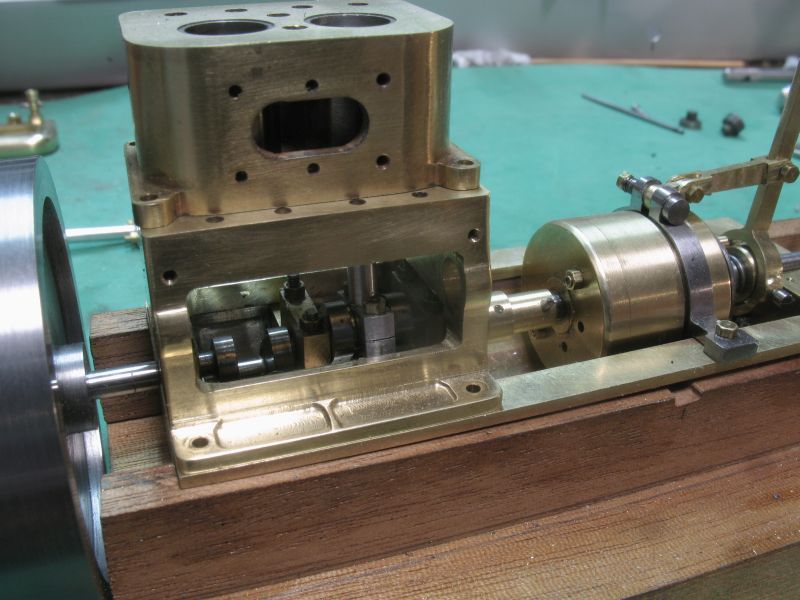

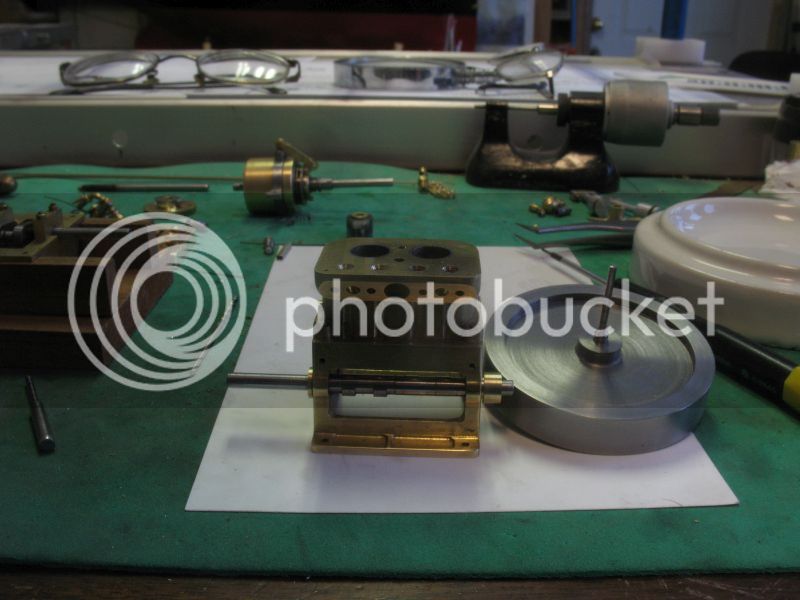

I have got the pistons in and moving smoothly now.

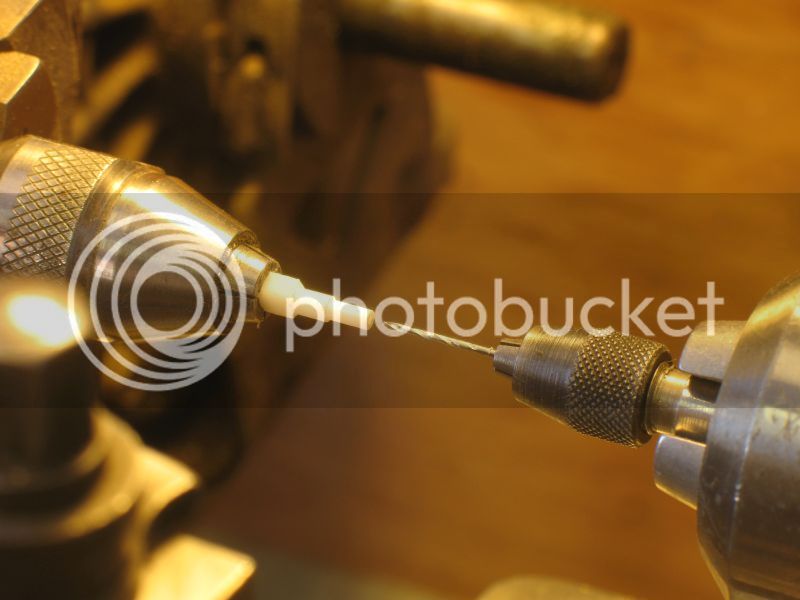

The next work has been on the camshaft, the first attempt ended in a costly mistake by grabbing the wrong handle on the mill I turned the table handle instead of the rotary table handle.

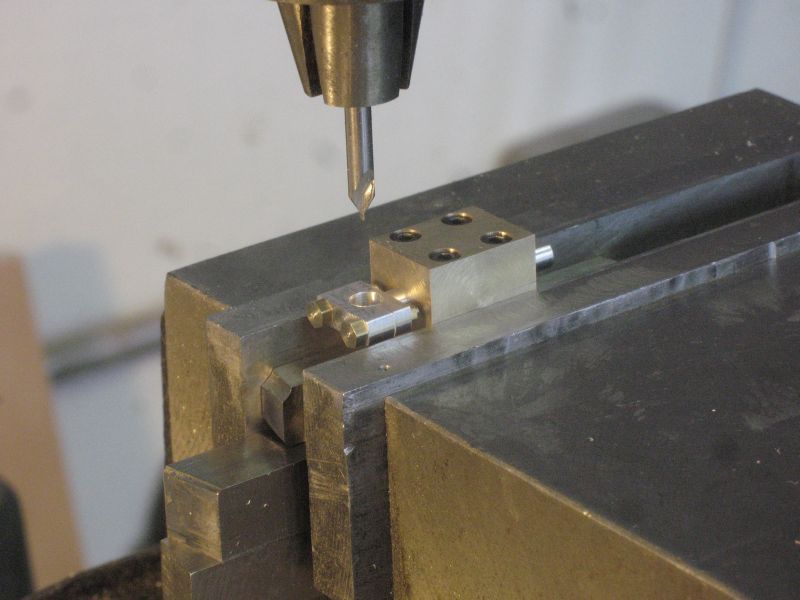

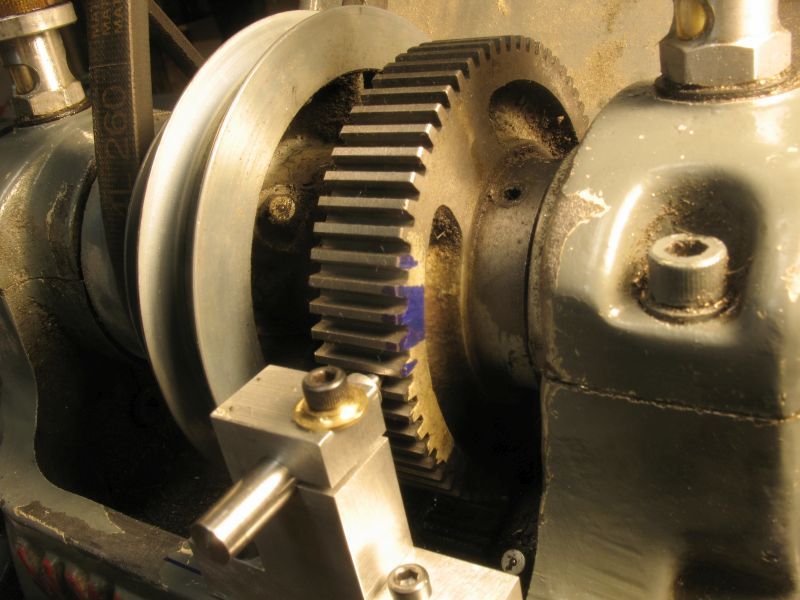

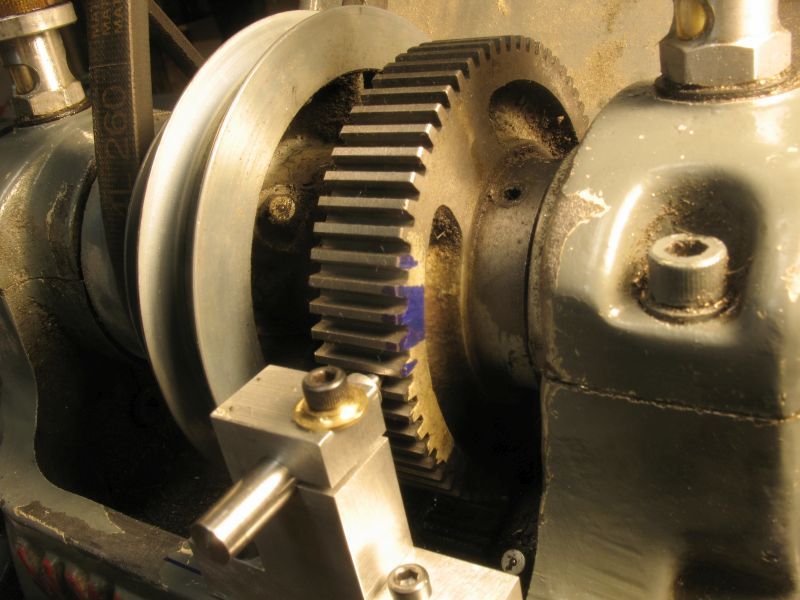

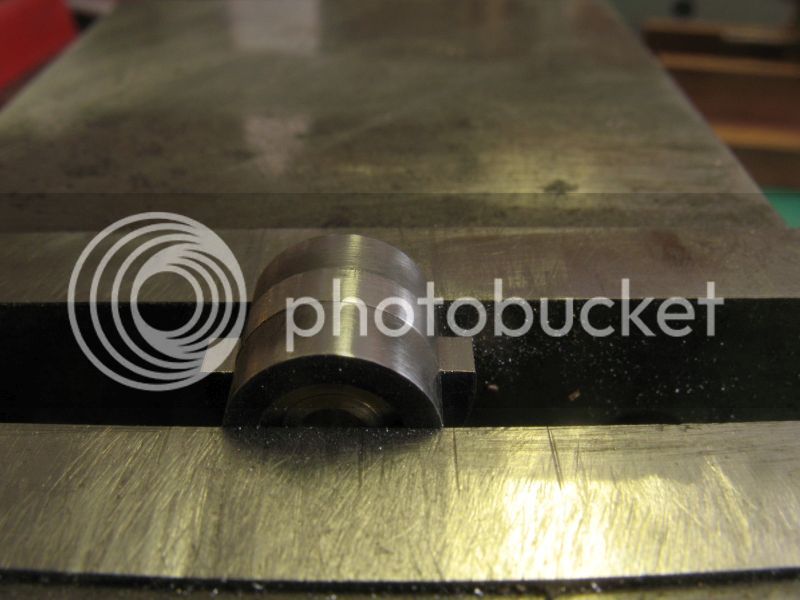

I changed course and decided to use the lathe as a shaper. I made the indent to lock the spindle using the main wheel of the back gear set up on the Myford.

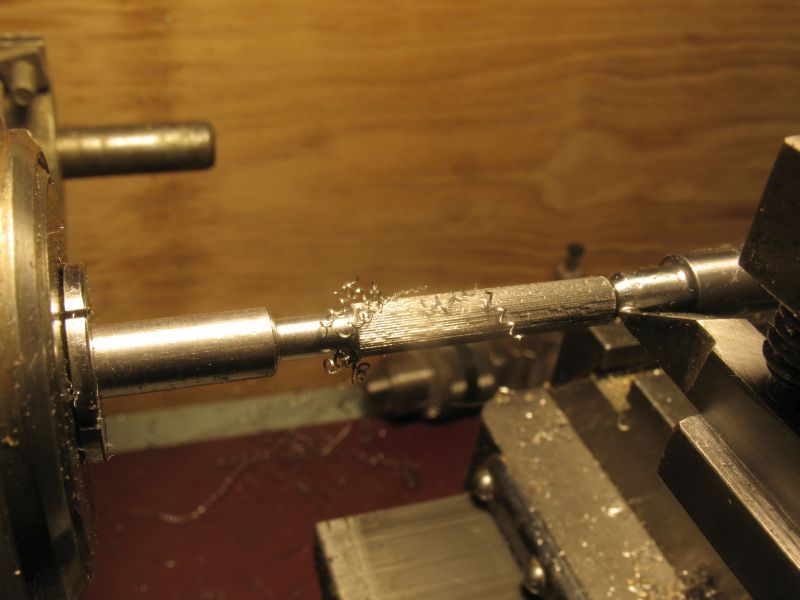

only .008" to go after cleaning and polishing I will bore and ream to .125 then drill for the locking pins and then part off and harden the cams, when I do the final positioning I will use some loctite then pin then to the shaft.

Mike

The next work has been on the camshaft, the first attempt ended in a costly mistake by grabbing the wrong handle on the mill I turned the table handle instead of the rotary table handle.

I changed course and decided to use the lathe as a shaper. I made the indent to lock the spindle using the main wheel of the back gear set up on the Myford.

only .008" to go after cleaning and polishing I will bore and ream to .125 then drill for the locking pins and then part off and harden the cams, when I do the final positioning I will use some loctite then pin then to the shaft.

Mike

mikemott

Well-Known Member

- Joined

- Oct 24, 2014

- Messages

- 53

- Reaction score

- 67

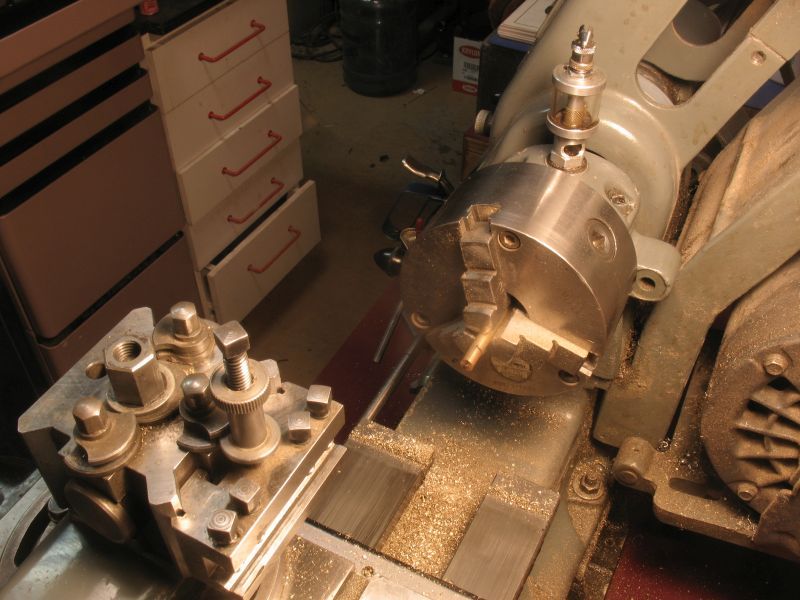

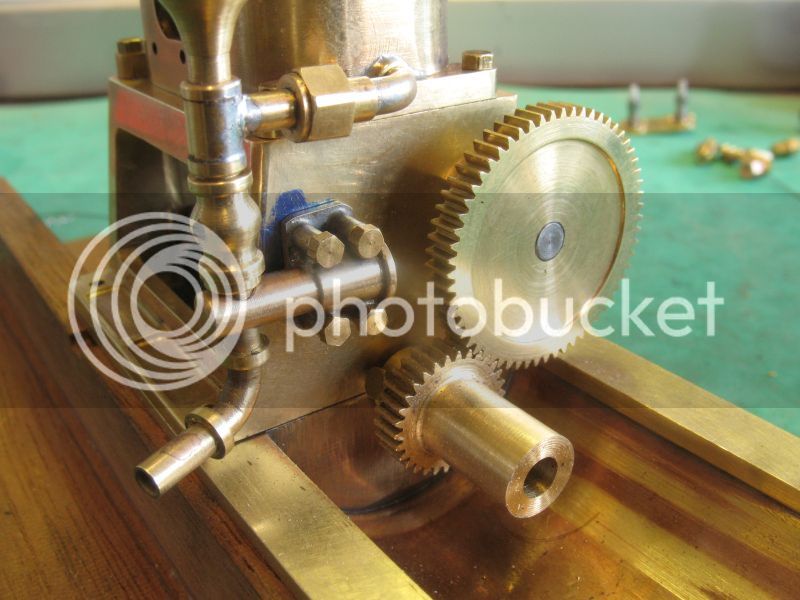

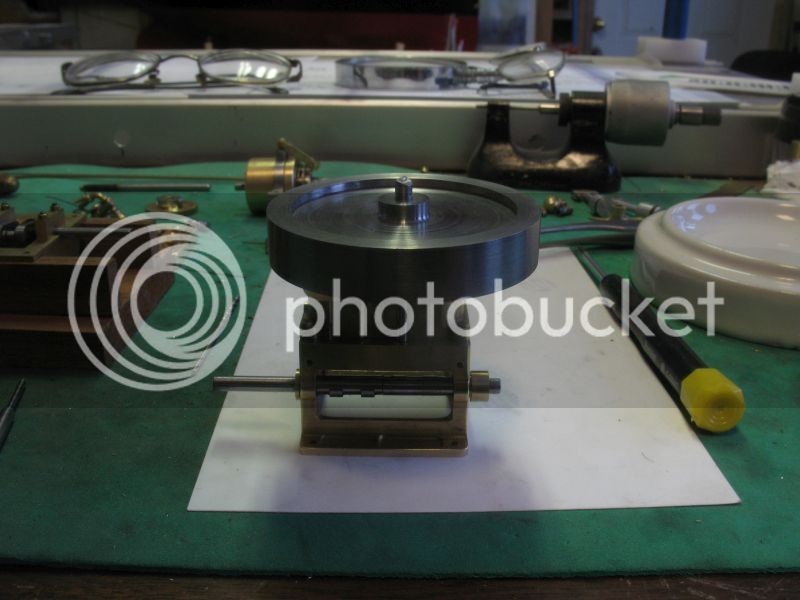

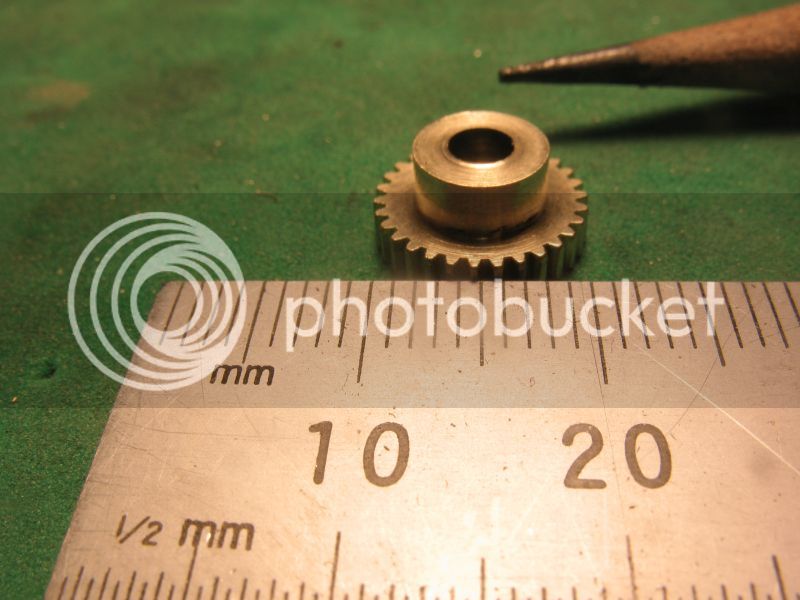

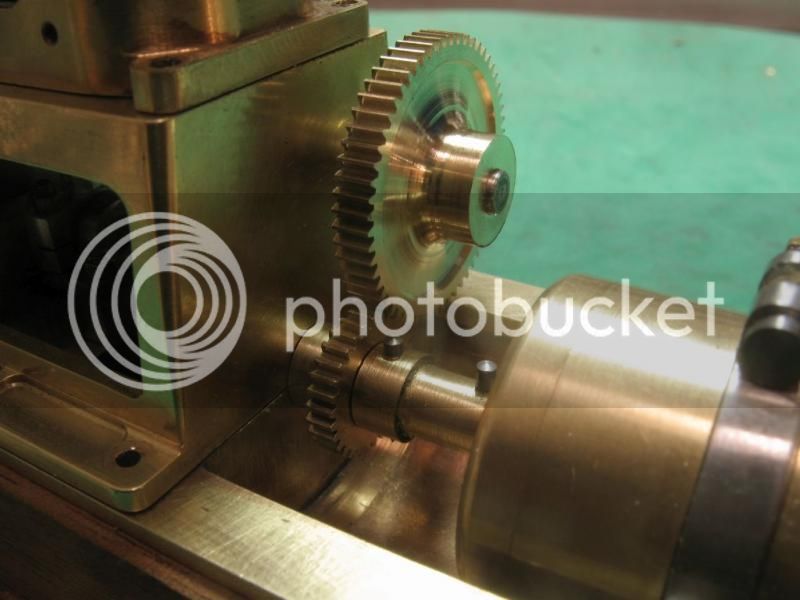

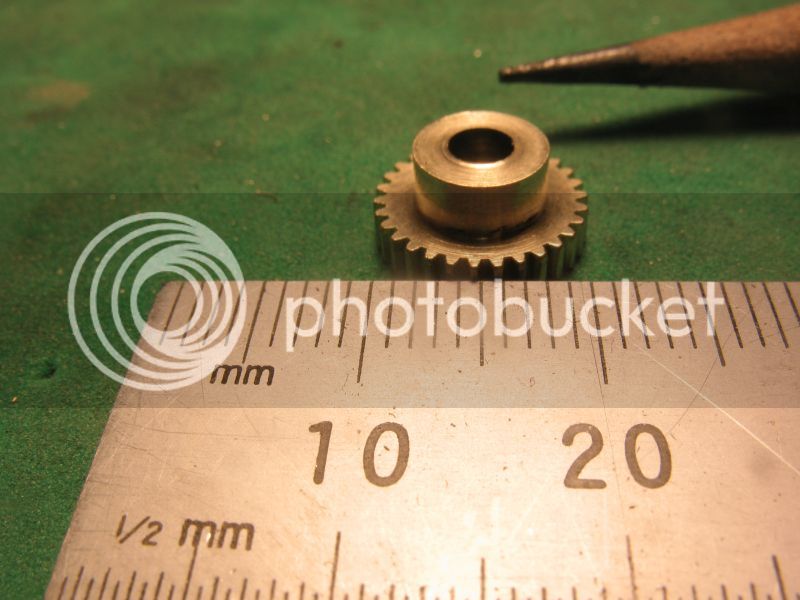

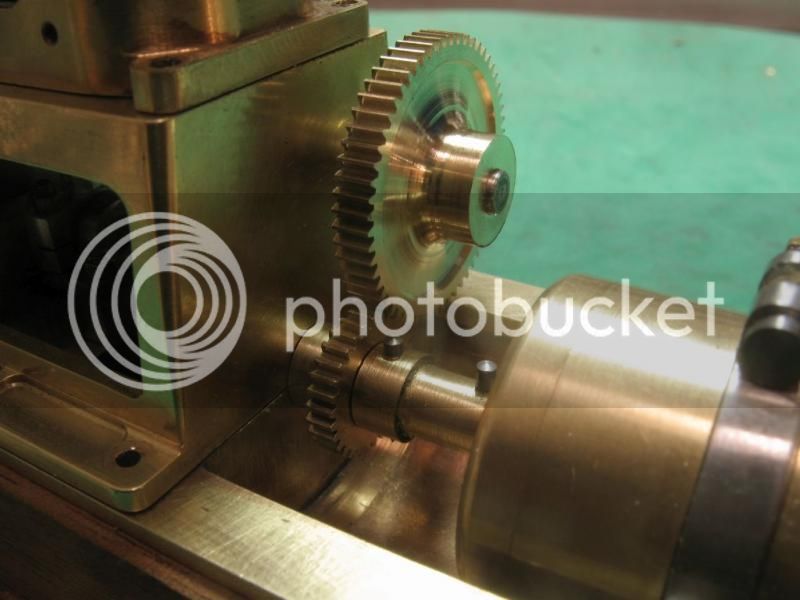

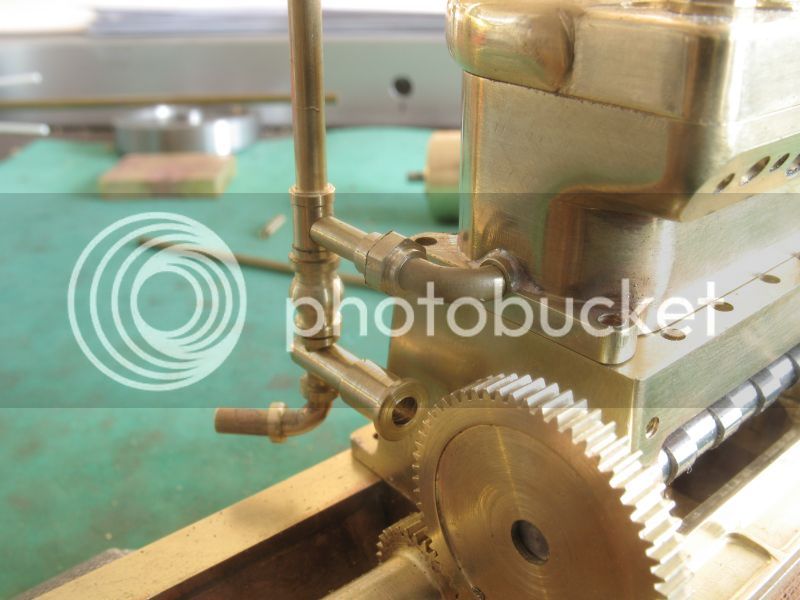

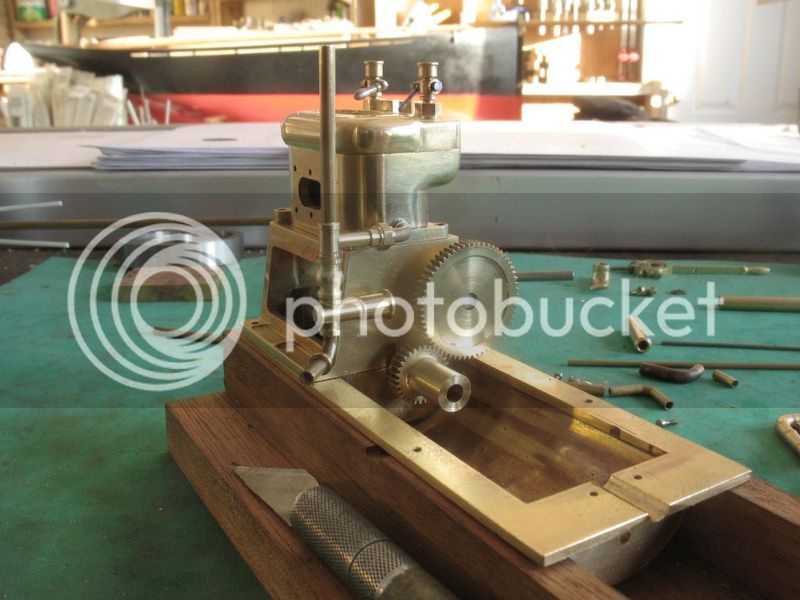

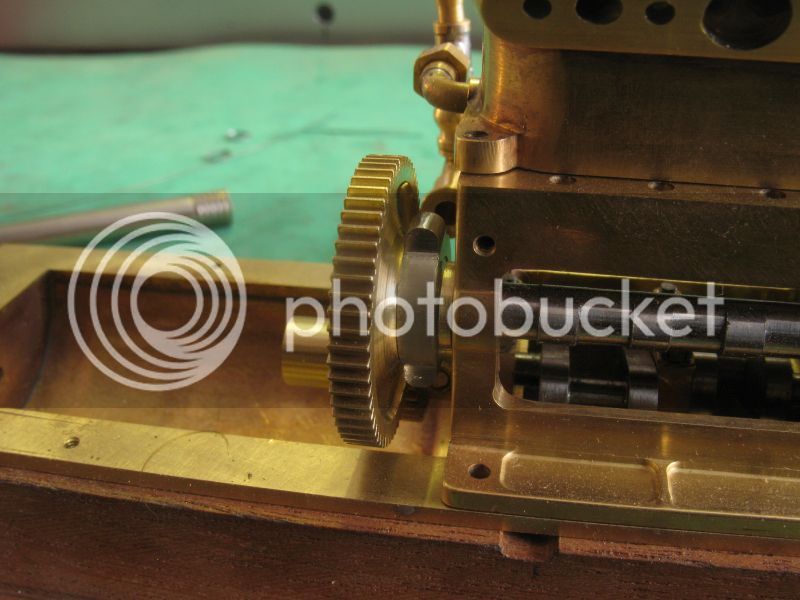

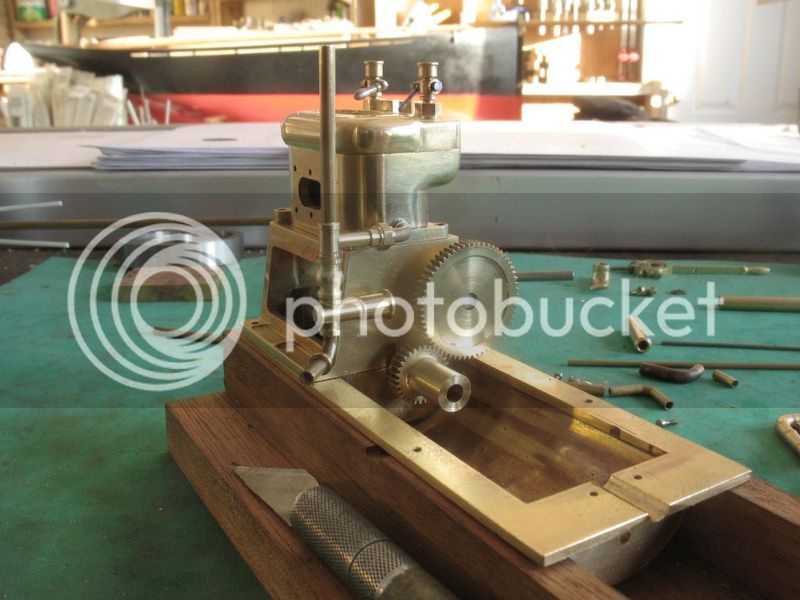

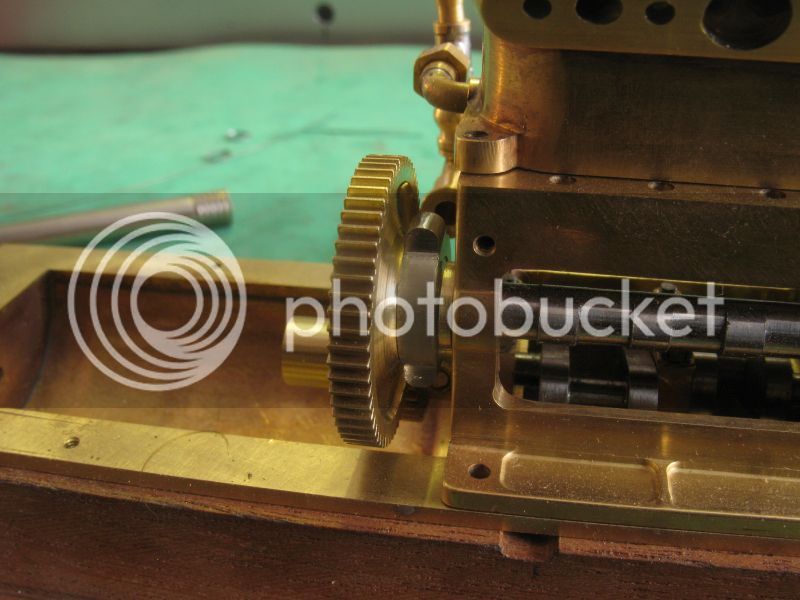

After finishing the camshaft lobes i made some cutter for the 75DP timing gears

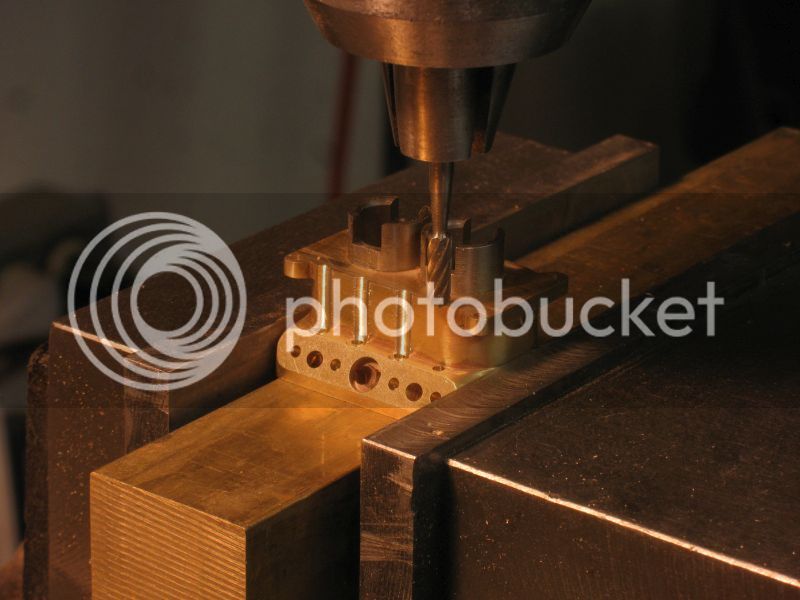

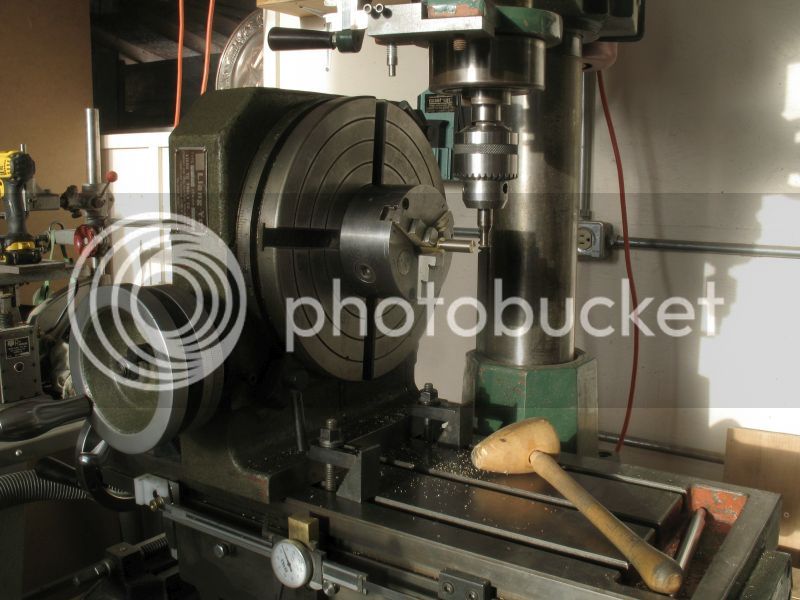

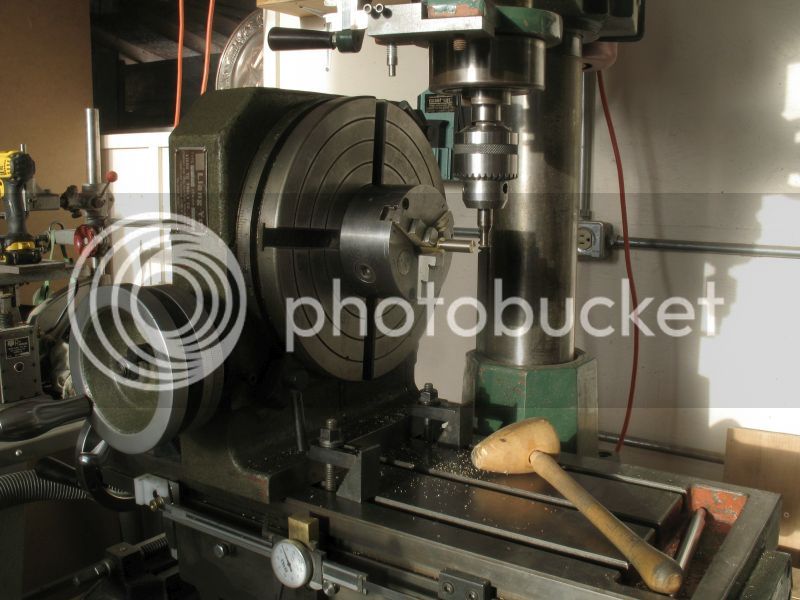

Then set up the rotary table in the vertical position to shape the gear blanks.

The quill and cutter were locked because I could only hold the cutter in my drill chuck and I will not use it for milling as it is dangerous.

back to the lathe for finish work

the gears meshed perfectly.

The gear is actually on backwards I need to still turn the eccentric for the water pump

Mike

Then set up the rotary table in the vertical position to shape the gear blanks.

The quill and cutter were locked because I could only hold the cutter in my drill chuck and I will not use it for milling as it is dangerous.

back to the lathe for finish work

the gears meshed perfectly.

The gear is actually on backwards I need to still turn the eccentric for the water pump

Mike

mikemott

Well-Known Member

- Joined

- Oct 24, 2014

- Messages

- 53

- Reaction score

- 67

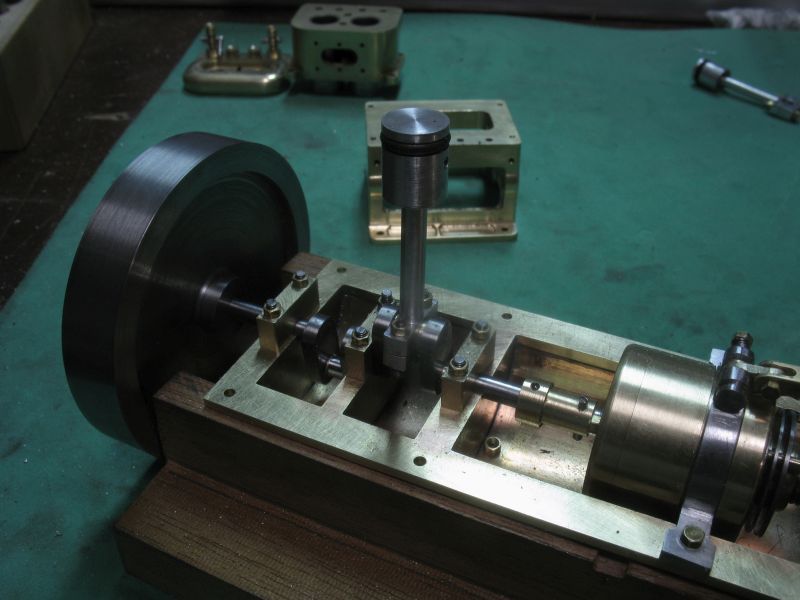

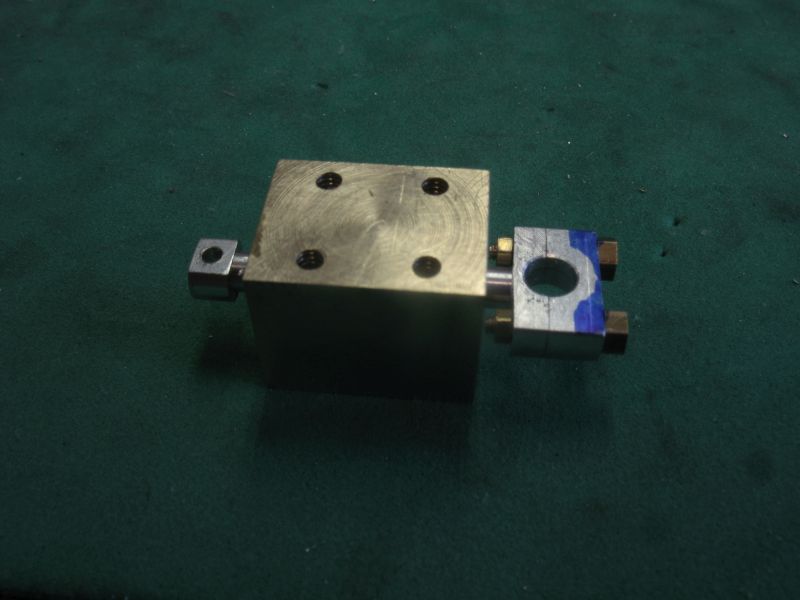

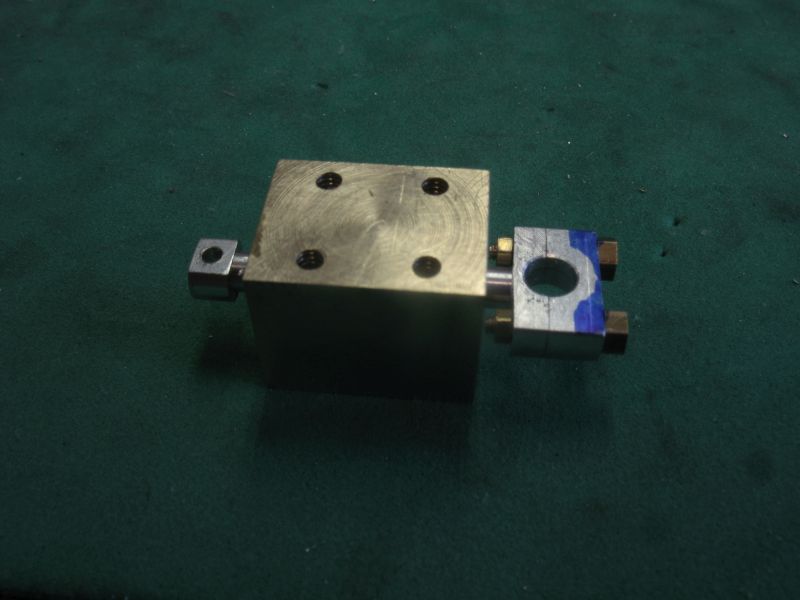

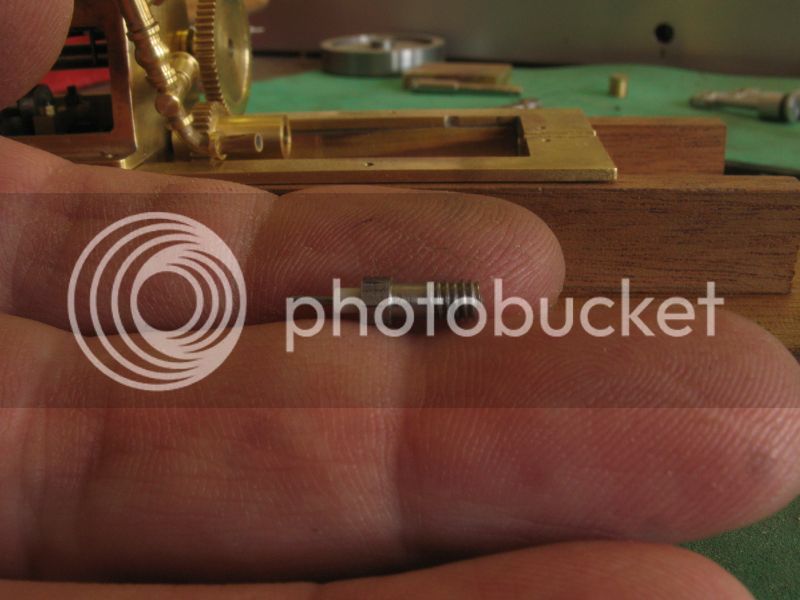

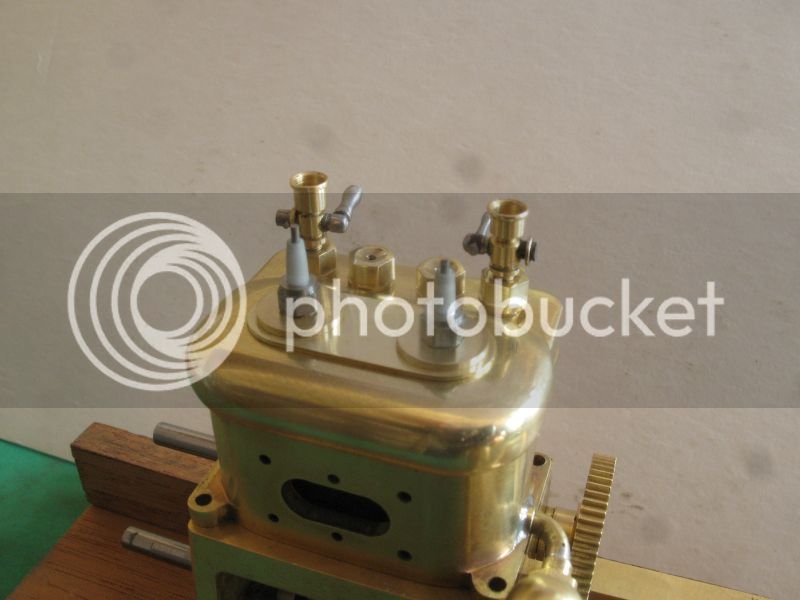

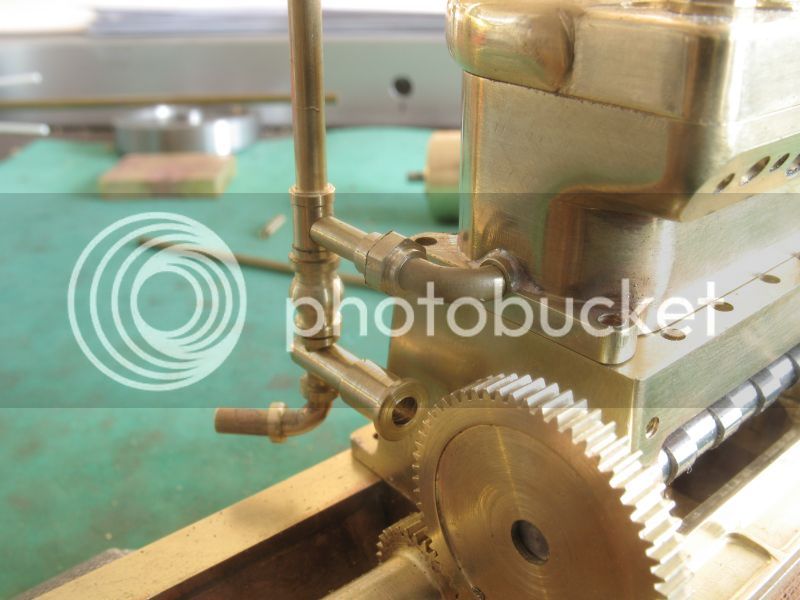

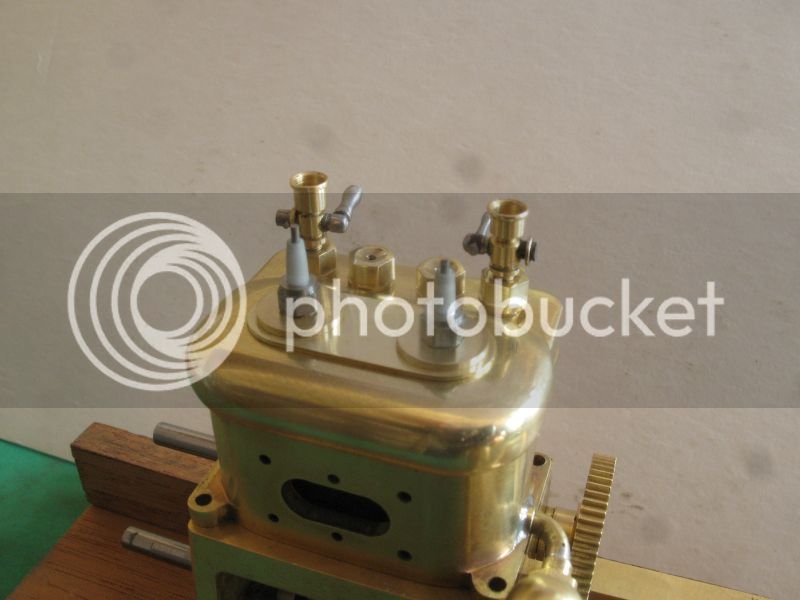

I have been busy on the engine working on the water pump and associated piping. I ended up making a 6x80 tap to make a couple of unions for the piping.

The small tubes were bent with some home made tube benders the tube was annealed and filled with some styrene rod bent then re heated to burn out the styrene, this worked very well.

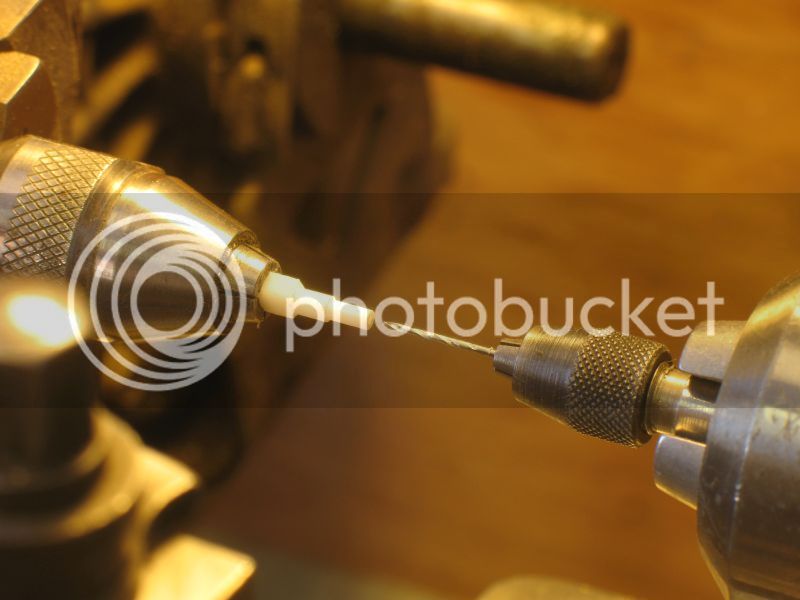

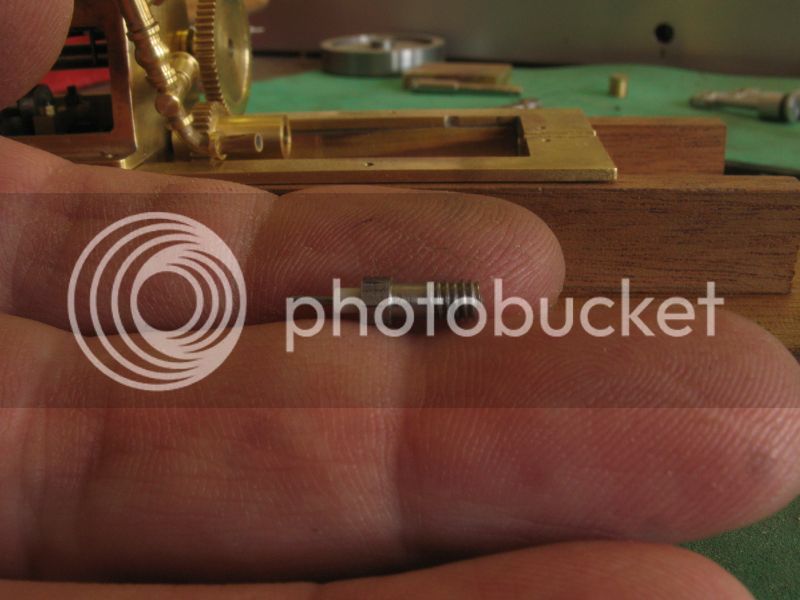

next I tackled the spark plugs I cut a couple of 1/8th square strips of a corian cutting board.

turned them down to .078" and drilled a .028" hole for the music wire electrode.

The body was made from a piece of Allen head key that was annealed it was 9/64 across the flats

I tested the plugs with a pietz cristal and they seemed to spark OK.

After filing and fitting the water cavity cover the circular plates have been turned from 3/8 bar stock.

some 00x90 round head screws were machined up from some 00x90 hex head bolts , the stock 00x90 round head screws were too large in diameter.

and to bring it all up to date the excentric cam parts are now being made from some stainless.

That is all for now

Mike

The small tubes were bent with some home made tube benders the tube was annealed and filled with some styrene rod bent then re heated to burn out the styrene, this worked very well.

next I tackled the spark plugs I cut a couple of 1/8th square strips of a corian cutting board.

turned them down to .078" and drilled a .028" hole for the music wire electrode.

The body was made from a piece of Allen head key that was annealed it was 9/64 across the flats

I tested the plugs with a pietz cristal and they seemed to spark OK.

After filing and fitting the water cavity cover the circular plates have been turned from 3/8 bar stock.

some 00x90 round head screws were machined up from some 00x90 hex head bolts , the stock 00x90 round head screws were too large in diameter.

and to bring it all up to date the excentric cam parts are now being made from some stainless.

That is all for now

Mike

Why can't I see any pictures in this thread?

Other threads e.g. the Merlin build show the pictures without any problem.

Dave

The Emerald Isle

Other threads e.g. the Merlin build show the pictures without any problem.

Dave

The Emerald Isle

Similar threads

- Replies

- 413

- Views

- 40K

- Replies

- 1

- Views

- 1K

- Replies

- 111

- Views

- 21K

- Replies

- 115

- Views

- 34K