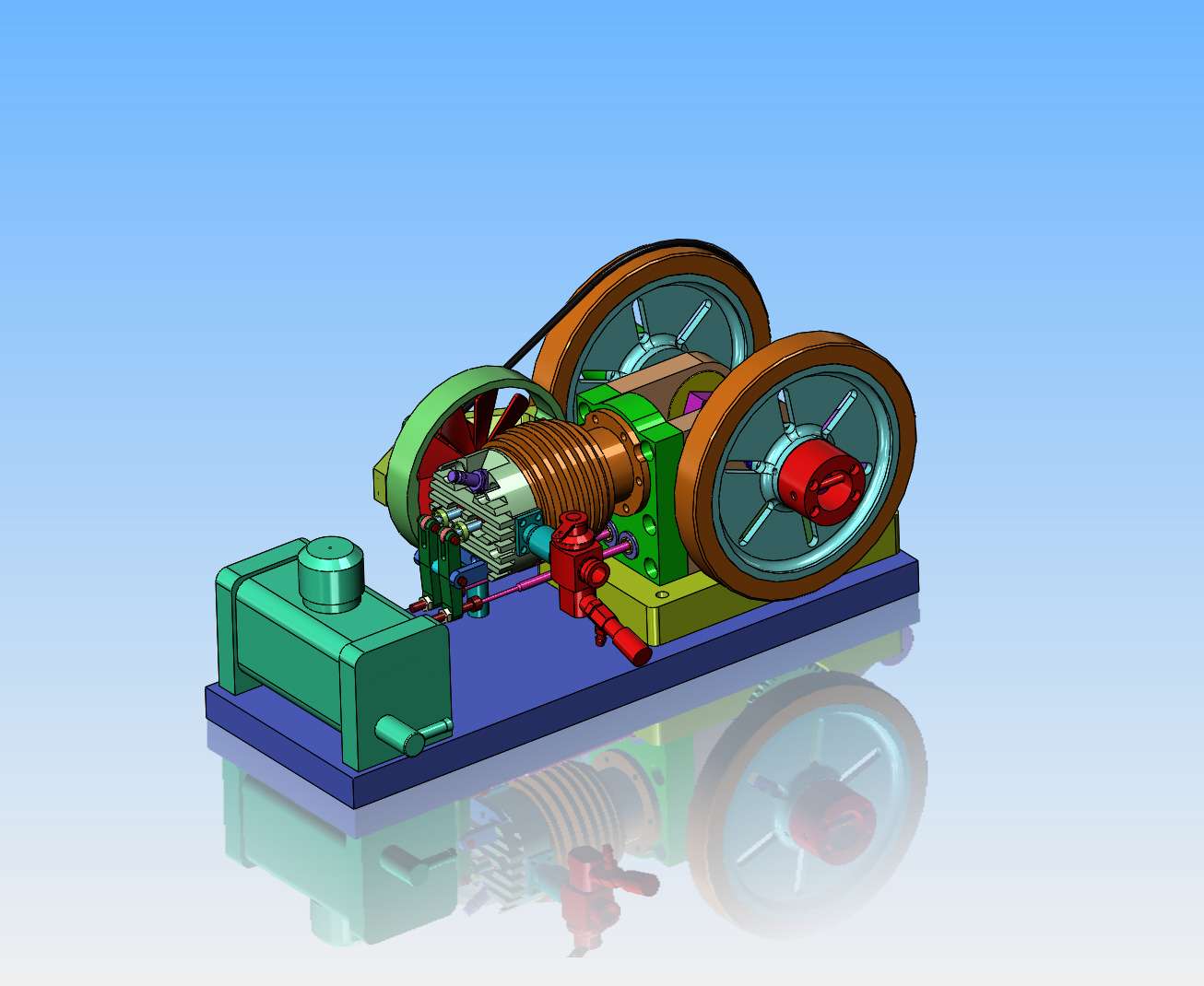

Okay---Just pulled the head off. This is a view of the inside of the cylinder head. There was nothing funky about the head gasket. There was nothing funky about the position of the sparkplug relative to the valves. The only thing I can see is that the spark from the center electrode to the side of the plug is happening on the side away from the valves. If I put a small brass washer between the sparkplug and the cylinder head, I hope to be able to re-tighten the sparkplug and have it so that the spark jumps to the valve side of the sparkplug. It seems highly improbable that this would cause a "no fire" situation, but when everything else has been checked, we start to seek out the improbable and correct it.