Mitchg07261995

Senior Member

- Joined

- Nov 12, 2012

- Messages

- 242

- Reaction score

- 53

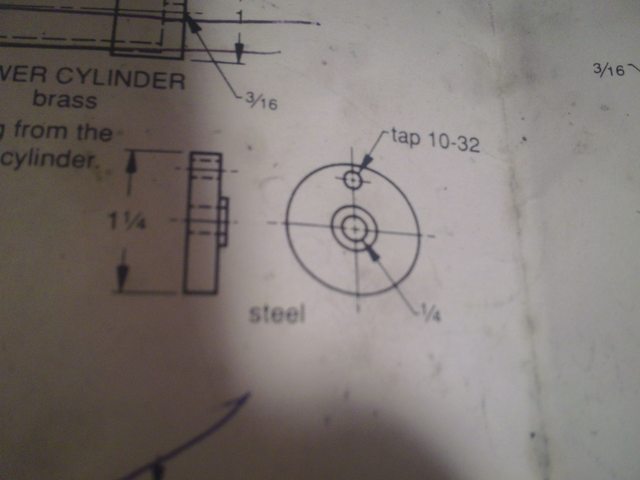

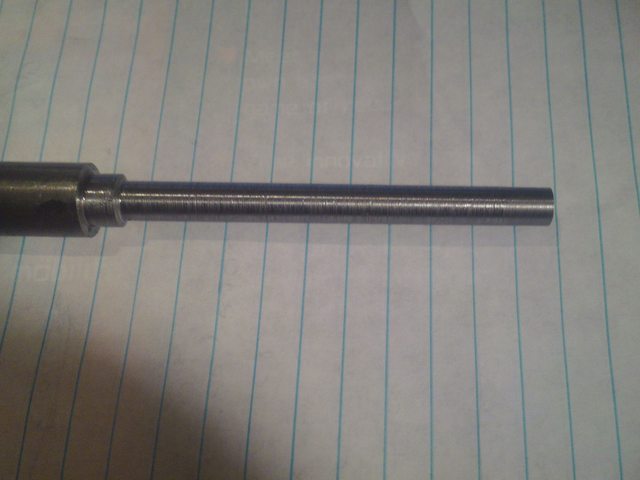

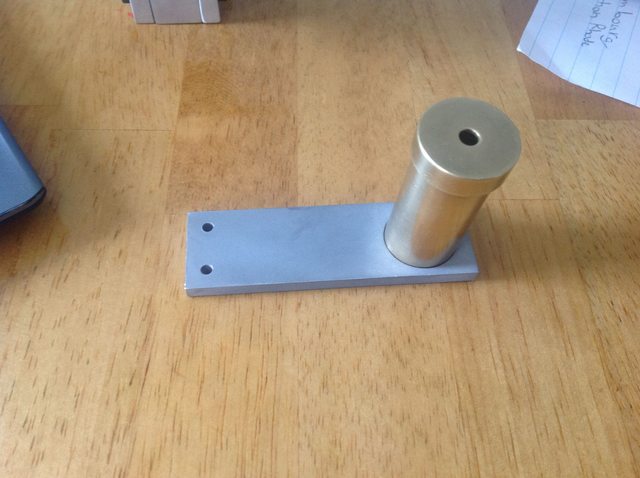

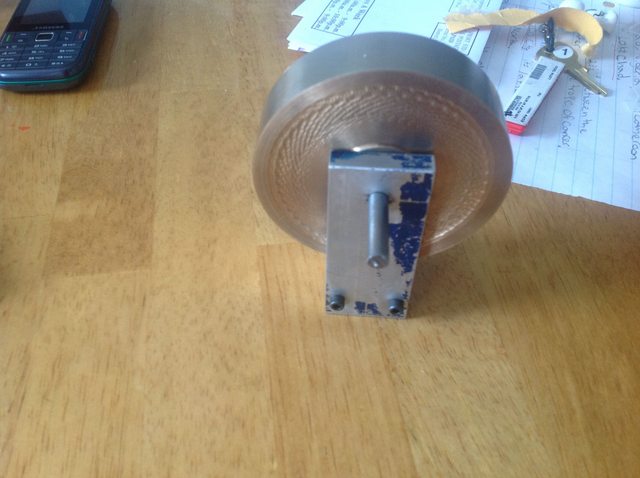

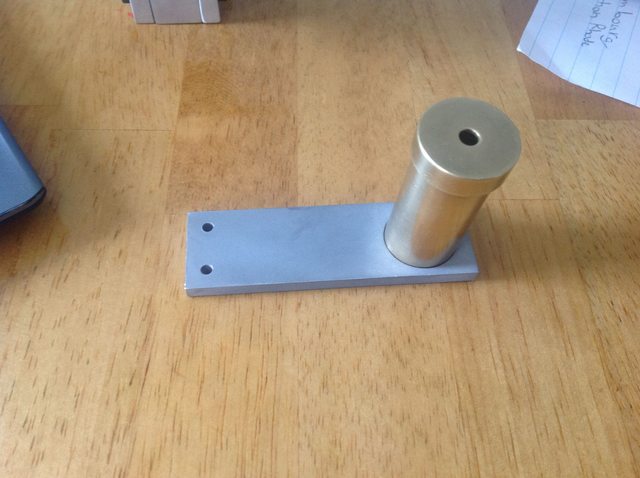

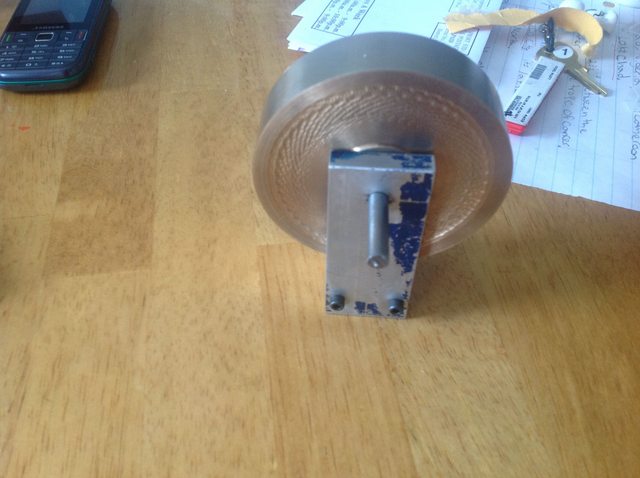

got some more work done today, one more part is finished the whole in the top just needs to be enlarged a little. Maybe .002'' im going about doing this by sanding it till the part that goes in the whole is a press fit

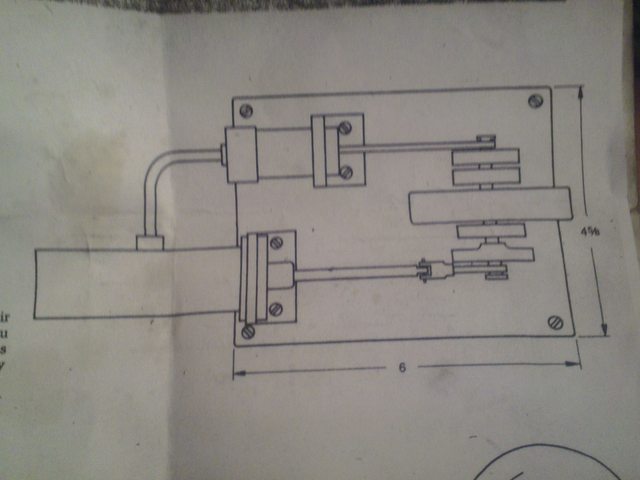

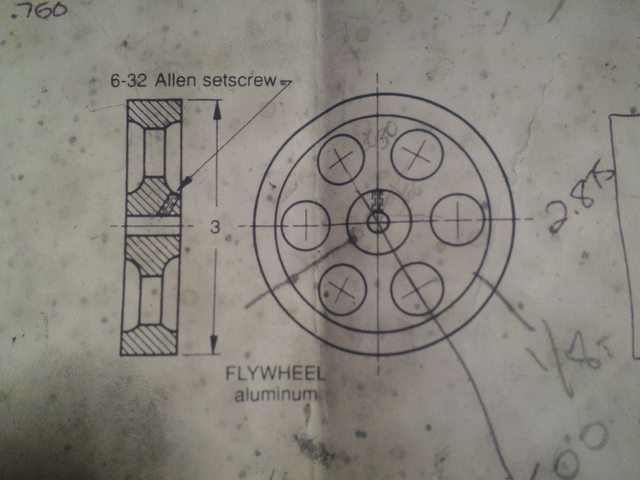

i modified the piece that my pal gave me, I need to make the space in between the part a little more wide so im taking about .010 at a time till i get the clearence for the flywheel that I need

thats all for now

Mitch

i modified the piece that my pal gave me, I need to make the space in between the part a little more wide so im taking about .010 at a time till i get the clearence for the flywheel that I need

thats all for now

Mitch