DICKEYBIRD

Well-Known Member

- Joined

- Sep 27, 2007

- Messages

- 653

- Reaction score

- 46

I did my good deed for the week last night & this morning.

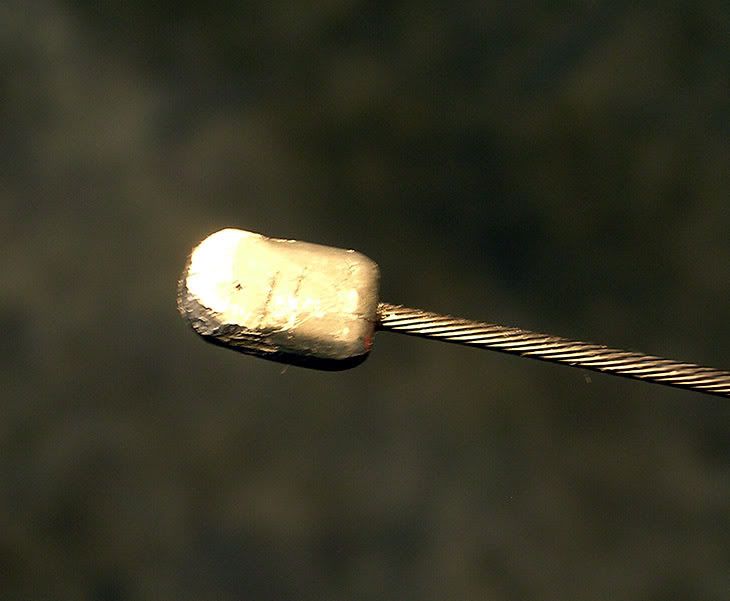

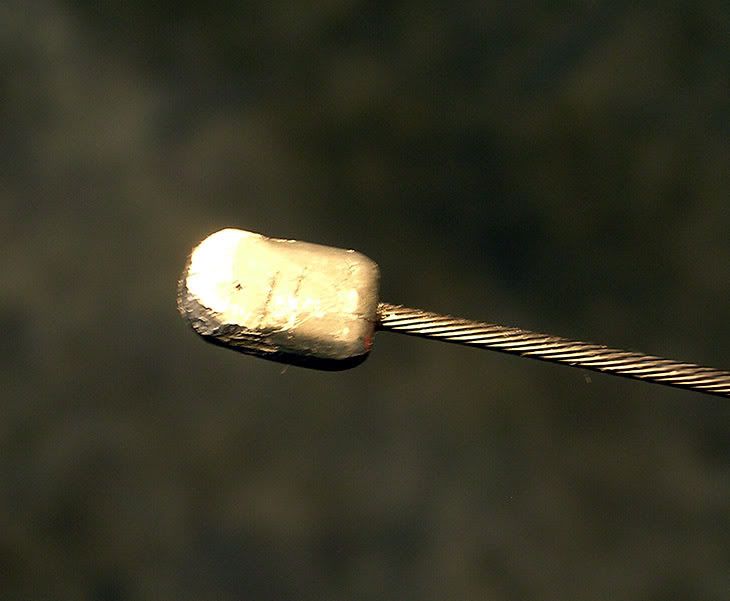

My almost blind neighbor's self-propelled mower cable end snapped about half-way through the mowing job his young son was doing. I didn't think he'd find a replacement cable any time soon so I volunteered to put the mighty powers of my garage R&D facility into immediate action.

The cable end was a swedged in place fitting that slipped over a peg spot-welded to the control lever. I clipped off most of the broken fitting and squared it up with a Dremel mounted stone. Next was an aluminum fitting with a milled-in slot to capture the modified end. The first try didn't give enough cable movement so I milled the slot longer and made a steel spacer to fill the gap. I made a cover plate to hold the whole mess together and held it on with 3 2-56 screws. I drilled a 1/4" hole in it to fit the peg and drilled/tapped the end of the peg for a 4-40 screw & washer to hold it on. The original one-time use retainer cap of course exploded into several pieces and there wasn't room for a simple cotter pin & drilled hole.

Works a treat and would only be about 437 times more expensive to make than a new cable would cost!

My almost blind neighbor's self-propelled mower cable end snapped about half-way through the mowing job his young son was doing. I didn't think he'd find a replacement cable any time soon so I volunteered to put the mighty powers of my garage R&D facility into immediate action.

The cable end was a swedged in place fitting that slipped over a peg spot-welded to the control lever. I clipped off most of the broken fitting and squared it up with a Dremel mounted stone. Next was an aluminum fitting with a milled-in slot to capture the modified end. The first try didn't give enough cable movement so I milled the slot longer and made a steel spacer to fill the gap. I made a cover plate to hold the whole mess together and held it on with 3 2-56 screws. I drilled a 1/4" hole in it to fit the peg and drilled/tapped the end of the peg for a 4-40 screw & washer to hold it on. The original one-time use retainer cap of course exploded into several pieces and there wasn't room for a simple cotter pin & drilled hole.

Works a treat and would only be about 437 times more expensive to make than a new cable would cost!