etw method of balancing

Balancing Small Engines

Notes on basic principles and practical methods of procedure

Basic Principles

by ET Westbury, 1951

sorry for the long post but i have found this formula most helpfull in building my engines hope it helps i have cut the text down to te basic formula

love the progress

First, weigh the piston, complete with its rings, gudgeon-pin, and pads, or other retaining devices (this is pure reciprocating weight). It may be mentioned that sufficient accuracy for this purpose may be obtained by using a simple spring balance (since it is only necessary to find comparative figures), and a suitable type of balance has been obtained from the surplus market, as advertised in THE MODEL ENGINEER.

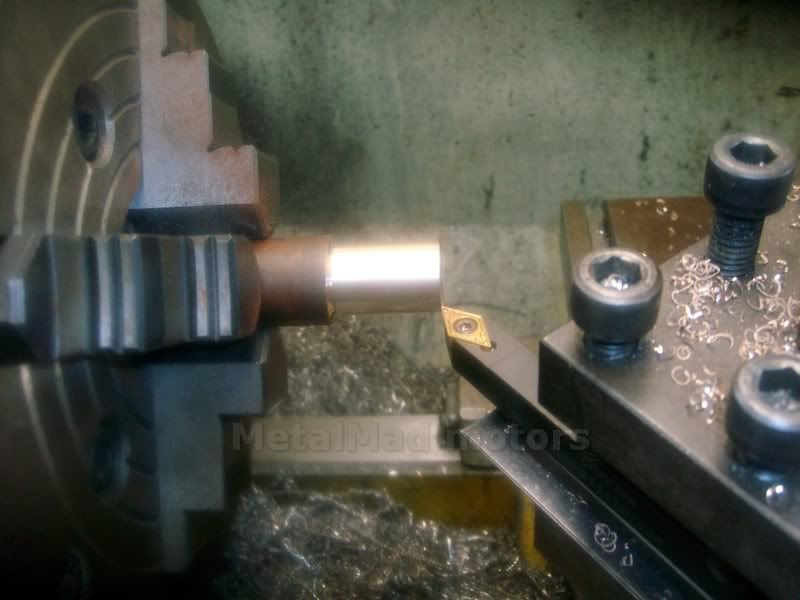

Second, weigh the two ends of the connecting-rod, either separately or simultaneously (preferably the latter) keeping the rod quite horizontal during the process. The small-end is taken as reciprocating weight, and the big-end as rotating weight.

Third, assess the amount of weight to be cancelled out in the counterweight. This is done by adding together reciprocating weights of the complete piston assembly, and the small-end of the rod, which (if we accept the proportion recommended above), is then halved, and added to the rotating weight of the big-end.

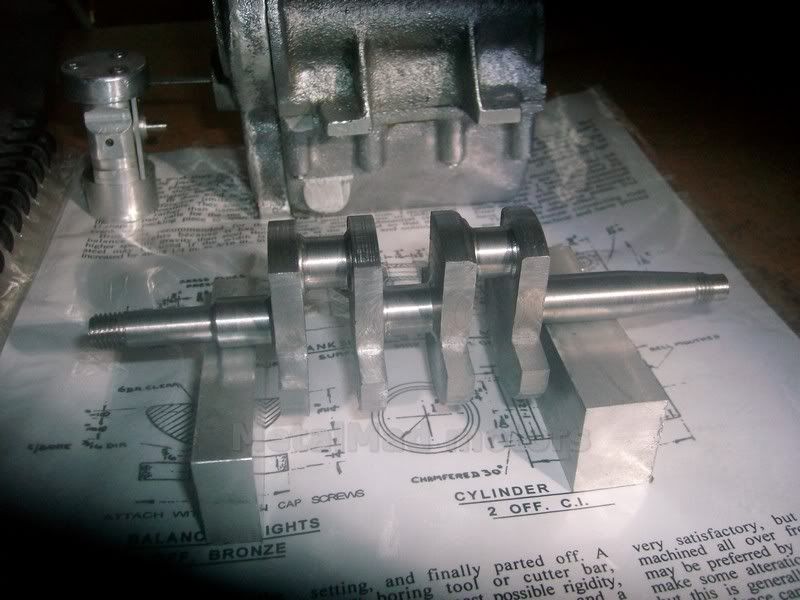

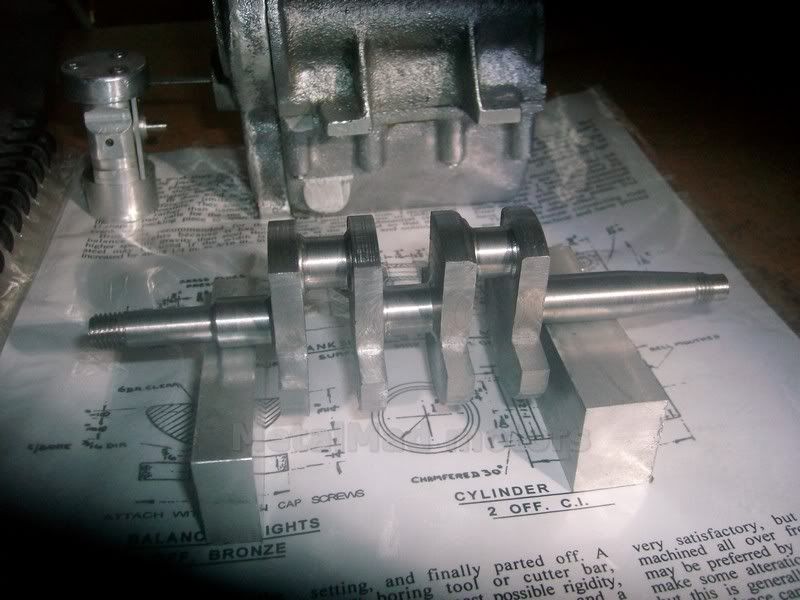

Fourth, the crankshaft is poised on knife edges or rollers, to act as a balance, and the assessed weight is hung on the crankpin; the counterweight is then adjusted until it "stays put" in any position of rotation. This may entail either adding or subtracting metal at the counterweight, such as by fitting lead "slugs" in suitable recesses where they cannot be thrown out centrifugally, or by filing or machining away the surplus. In some cases, lightness of the balance weight may be remedied by reducing the web on the crankpin side, or enlarging the centre hole in the later, always having due regard for retaining a margin of mechanical safety.

[Ron: Notice the "knife-edges" in the photo? Looks to me like two pieces of drill rod held in position on the leveled surface-plate by four small lumps of modelling clay. That is an idea well worth remembering!]

The weight necessary to carry out this operation may be made up from sand, lead shot, or any suitable material to hand; as may be seen, metal washers were used in the case illustrated. In the absence of a scale pan, a small bag may be used. It is important that the means of suspension on the crankpin should be arranged to produce the minimum friction. In the example shown, a small plug was made to fit inside the hollow crankpin (its weight being duly allowed for), having an extended pin of small diameter, on which the hook of the scale pan was hung.

The figures in the example illustrated are as follows:

Piston, with rings and gudgeon-pin .. 83 grms.

Small-end of connecting-rod .. 21 "

Big-end of connecting-rod .. 25 "

(83 + 21)

----------- + 25 = 77 grms

2

(the amount to be cancelled out by counterweight)

Should the designer adopt a different figure for the proportion of reciprocating weight to be balanced, this part of the calculation must be suitably modified. This formula, however, has been used with success, not only in models, but also for larger engines which have had to work under exacting conditions.

I have described this procedure in detail, as it is of interest to a large number of readers, to judge by the number of individual queries I have had to deal with, and I trust that this will clear away the last remnants of mystery regarding this subject.

I have stated that these conditions apply to any orthodox single-cylinder engine; it is also correct for machines having a similar order of motion, such as high-speed pumps or air compressors. Balancing problems should not be confused with effects caused by working pressures, though these produce their own reactions, and may affect smoothness of working. In many small machines which are not required to run at very high speeds, little attention is given to the finer points of balancing, and within certain limits, the results are fairly satisfactory.