You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Wallaby

- Thread starter metalmad

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

- Joined

- Nov 12, 2009

- Messages

- 1,427

- Reaction score

- 221

Hi guys

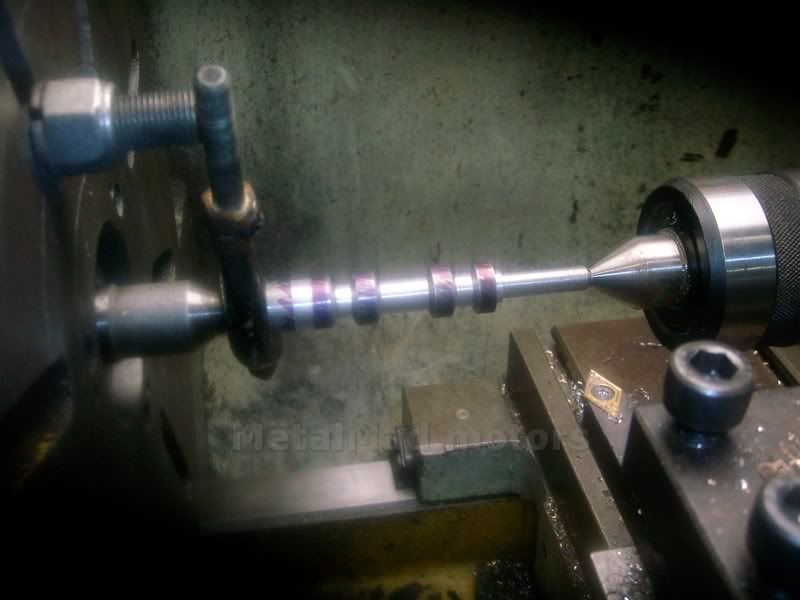

I finished roughing out the cam today and will make up the jig for the cam turning this week, i guess.

Once Ive done the cams lobes, ill take the journals down to size and tidy it up

I finished roughing out the cam today and will make up the jig for the cam turning this week, i guess.

Once Ive done the cams lobes, ill take the journals down to size and tidy it up

Pete,

Are the cams made the usual Westbury way, that is a little holding jig with a timing plate on the end and you cut each facet on the lathe?

If so, just be careful, it is very easy to make your cam backwards. DAMHIK. But once you get it right, following his instructions, it makes a very nice cam indeed. To blend in the flats, I just used a bit of very fine emery strip stuck onto a lolly pop stick, and turned it in the lathe. It only takes a few seconds on each lobe.

I threw away the jigs I made on my last big clearout about 3 years ago, but they are worth keeping as they could be sent around the world to help others out who are building the same engine, as they weigh very little.

Best of luck

John

Are the cams made the usual Westbury way, that is a little holding jig with a timing plate on the end and you cut each facet on the lathe?

If so, just be careful, it is very easy to make your cam backwards. DAMHIK. But once you get it right, following his instructions, it makes a very nice cam indeed. To blend in the flats, I just used a bit of very fine emery strip stuck onto a lolly pop stick, and turned it in the lathe. It only takes a few seconds on each lobe.

I threw away the jigs I made on my last big clearout about 3 years ago, but they are worth keeping as they could be sent around the world to help others out who are building the same engine, as they weigh very little.

Best of luck

John

- Joined

- Nov 12, 2009

- Messages

- 1,427

- Reaction score

- 221

Hi Bogs

Thanks for the tip, anything could happen :big:

I very much doubt anybody would want this jig John :big:

It is just a couple of holes in two end pieces, that give me the needed 0.65625 offset and a timing plate and pointer with a tapered hole.

The whole lot will go between centres in the lathe but I don't plan on spending much time on a one off jig as long as its functional.

I regret putting that last pic up a little as it looks much nicer in real life.

(The joys of close up photography i guess)

Pete

Thanks for the tip, anything could happen :big:

I very much doubt anybody would want this jig John :big:

It is just a couple of holes in two end pieces, that give me the needed 0.65625 offset and a timing plate and pointer with a tapered hole.

The whole lot will go between centres in the lathe but I don't plan on spending much time on a one off jig as long as its functional.

I regret putting that last pic up a little as it looks much nicer in real life.

(The joys of close up photography i guess)

Pete

Hi Pete

Go to Model Engine News site

http://www.modelenginenews.org/

Go to Resources Site map , Alpha Index.

Sorry about that....

Click on CamCalc, and the page will open

The program will compute lifts and rotation for any given input parameters and give an output in a spreadsheet format. Usually you would use this on a milling machine with a dividing head. Nice reading anyway.

Dave

Go to Model Engine News site

http://www.modelenginenews.org/

Go to Resources Site map , Alpha Index.

Sorry about that....

Click on CamCalc, and the page will open

The program will compute lifts and rotation for any given input parameters and give an output in a spreadsheet format. Usually you would use this on a milling machine with a dividing head. Nice reading anyway.

Dave

bezalel2000

Well-Known Member

- Joined

- May 8, 2011

- Messages

- 316

- Reaction score

- 7

metalmad said:I regret putting that last pic up a little as it looks much nicer in real life.

(The joys of close up photography i guess)

I wish mine looked as good.

but then the swarf ain't been removed from mine yet :big:

looking Good Pete.

Oh! and if you do a good job on the cam jig - I don't mind "hand me downs" ;D

Bez

- Joined

- Nov 12, 2009

- Messages

- 1,427

- Reaction score

- 221

Hi Dave

Ive followed your link a few times now with the intention of having a look at Camcalc and every time got sidetracked by all the wonderful engine builds on that site :big:

Hi Bez

your welcome to it buddy but be aware I'm going to build it from whatever i pick up off the floor ;D

Wow John

That Cam looks great !!

And as far as CNC goes

well maybe one day :big:

Pete

Ive followed your link a few times now with the intention of having a look at Camcalc and every time got sidetracked by all the wonderful engine builds on that site :big:

Hi Bez

your welcome to it buddy but be aware I'm going to build it from whatever i pick up off the floor ;D

Wow John

That Cam looks great !!

And as far as CNC goes

well maybe one day :big:

Pete

- Joined

- Nov 12, 2009

- Messages

- 1,427

- Reaction score

- 221

I got in a couple of hours after work today, but did not get the jig finished.

It still needs clamping bolts or something.

I do not want the journals marked even if they are not to size yet so i think i will split the side and have clamping bolts, the other center anything goes as long as it does not move.

Pete

It still needs clamping bolts or something.

I do not want the journals marked even if they are not to size yet so i think i will split the side and have clamping bolts, the other center anything goes as long as it does not move.

Pete

- Joined

- Nov 12, 2009

- Messages

- 1,427

- Reaction score

- 221

Hi Dave

Thank you very much for saying that, it helps a great deal to know my engines are appreciated !!

I only need to make the timing wheel and pointer now and i can start doing the lobes of the Cam, that will be interesting :big:

Hope to get into it this week some time.

Pete

Thank you very much for saying that, it helps a great deal to know my engines are appreciated !!

I only need to make the timing wheel and pointer now and i can start doing the lobes of the Cam, that will be interesting :big:

Hope to get into it this week some time.

Pete

metalmad said:I got in a couple of hours after work today, but did not get the jig finished.

Looks like a camshaft is about to be cut. Is that the cam in the fixture?

- Joined

- Nov 12, 2009

- Messages

- 1,427

- Reaction score

- 221

Hi Steve

Yep that's the blank and i will cut it, but will it end up a Cam, dunno?? :big:

I'm using the standard ETW Cam timing for my first attempt, but if she sounds too tame, i may try something warmer later.

That's a whole new learning curve right there. :big:

As soon as i source a 2BA nut for the end of the Cam, ill give it a shot, but i may have to make one as BA seems even harder to get then UNC.

Pete

Yep that's the blank and i will cut it, but will it end up a Cam, dunno?? :big:

I'm using the standard ETW Cam timing for my first attempt, but if she sounds too tame, i may try something warmer later.

That's a whole new learning curve right there. :big:

As soon as i source a 2BA nut for the end of the Cam, ill give it a shot, but i may have to make one as BA seems even harder to get then UNC.

Pete

bezalel2000

Well-Known Member

- Joined

- May 8, 2011

- Messages

- 316

- Reaction score

- 7

Hang in there mate, There's a couple in the post heading your way

;D

;D