- Joined

- Jan 17, 2009

- Messages

- 1,081

- Reaction score

- 278

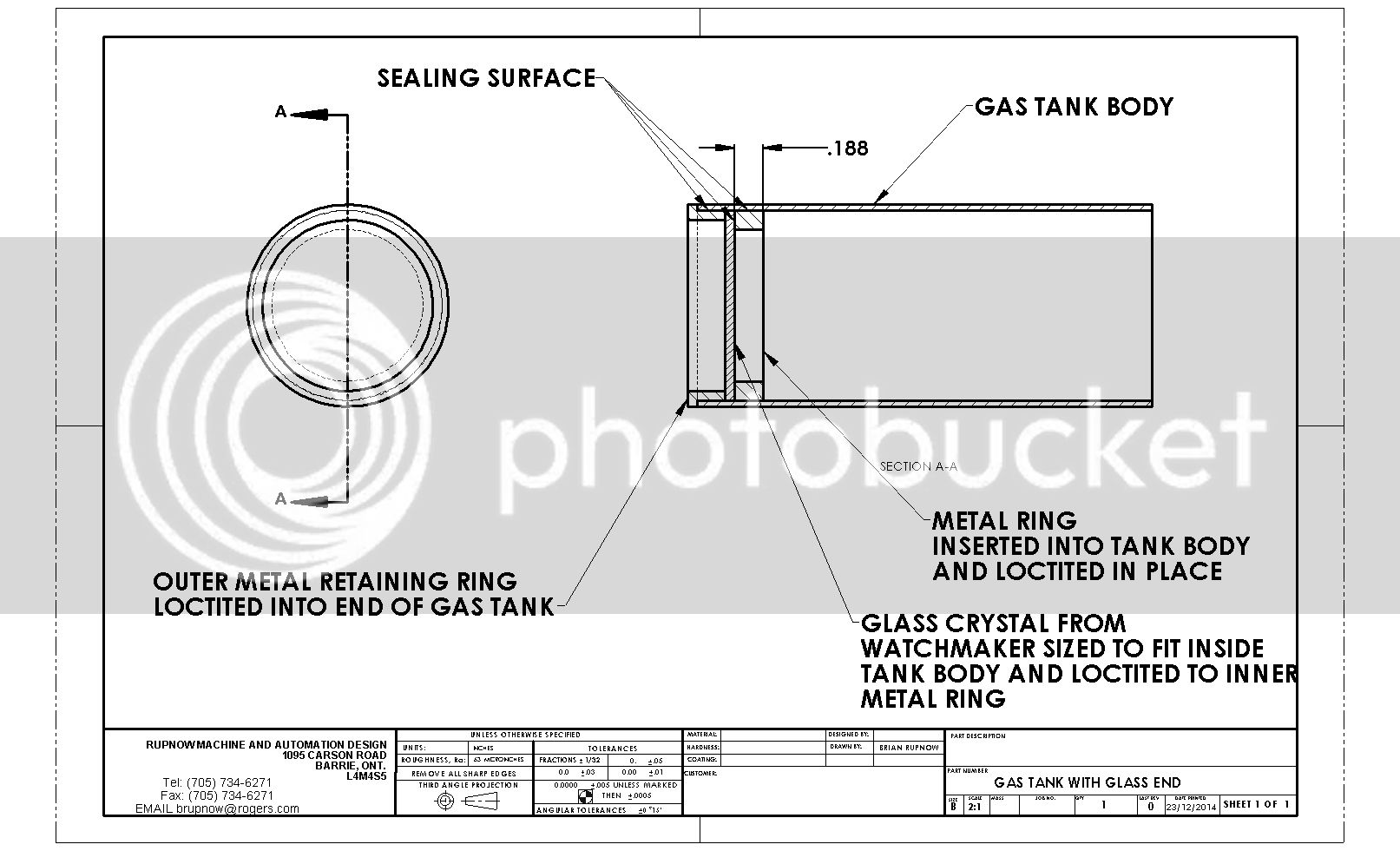

I want to build a gas tank (Coleman) with one side transparent.

Copper tube, with one recessed ring, inside, to register the transparent side.

What material and glue work for this application?

Copper tube, with one recessed ring, inside, to register the transparent side.

What material and glue work for this application?