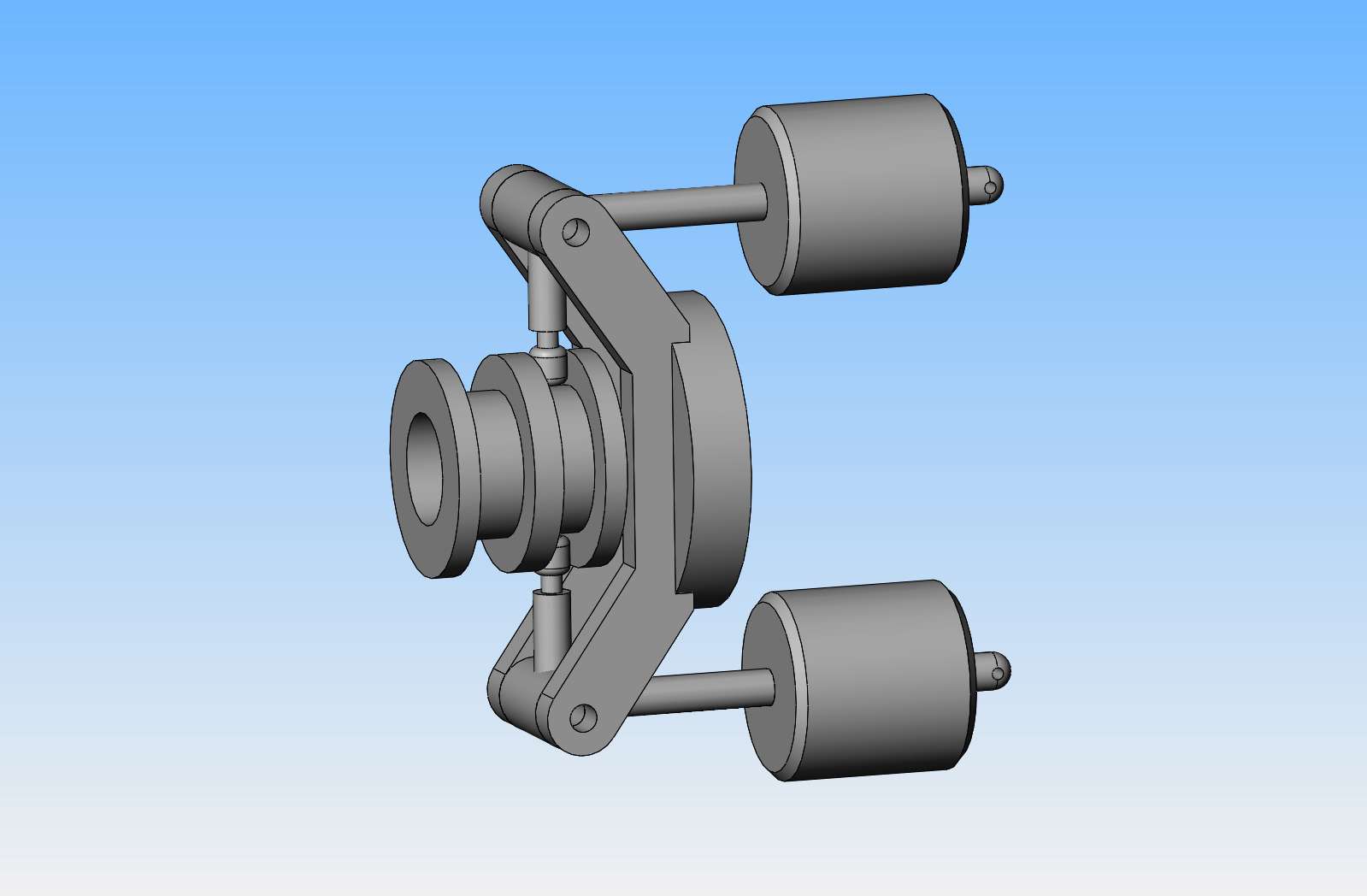

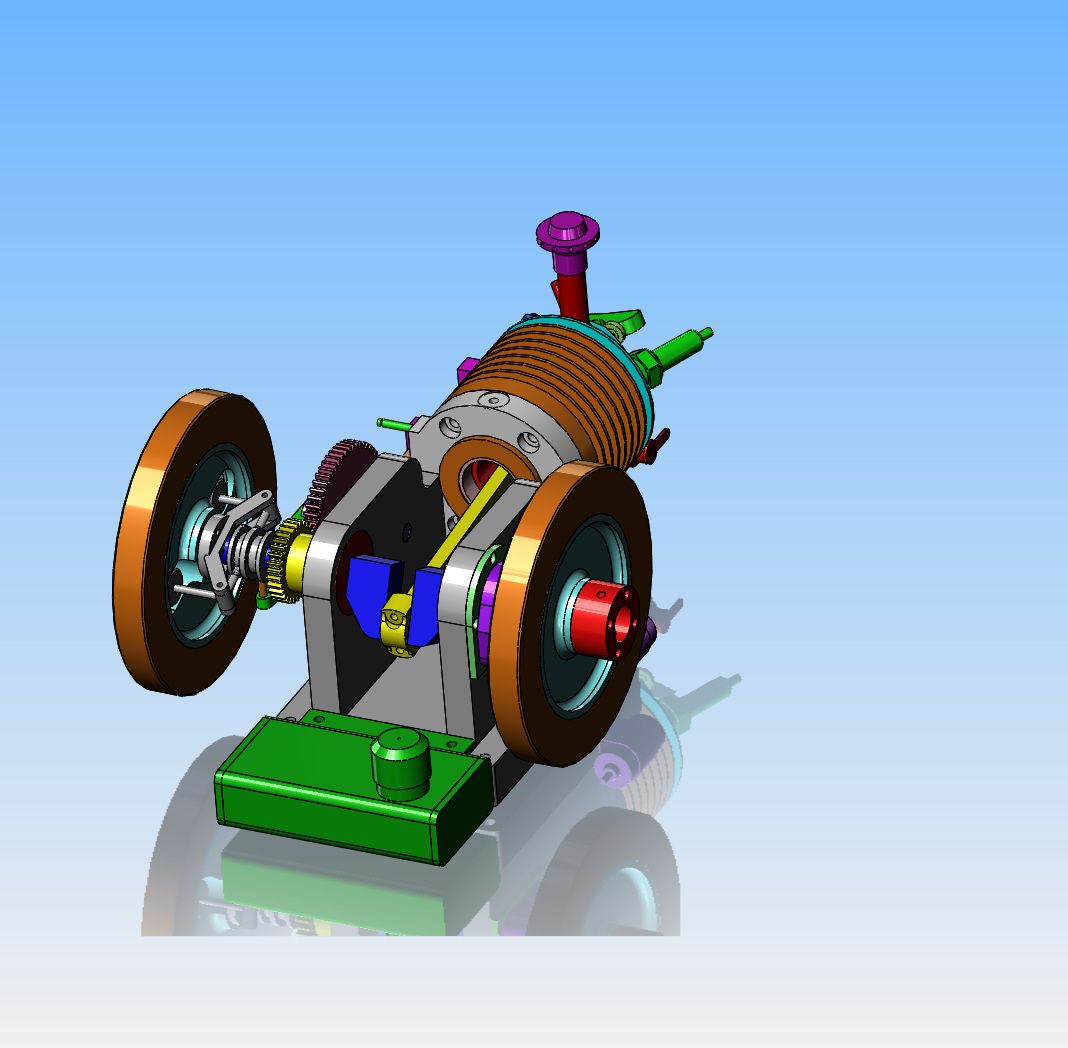

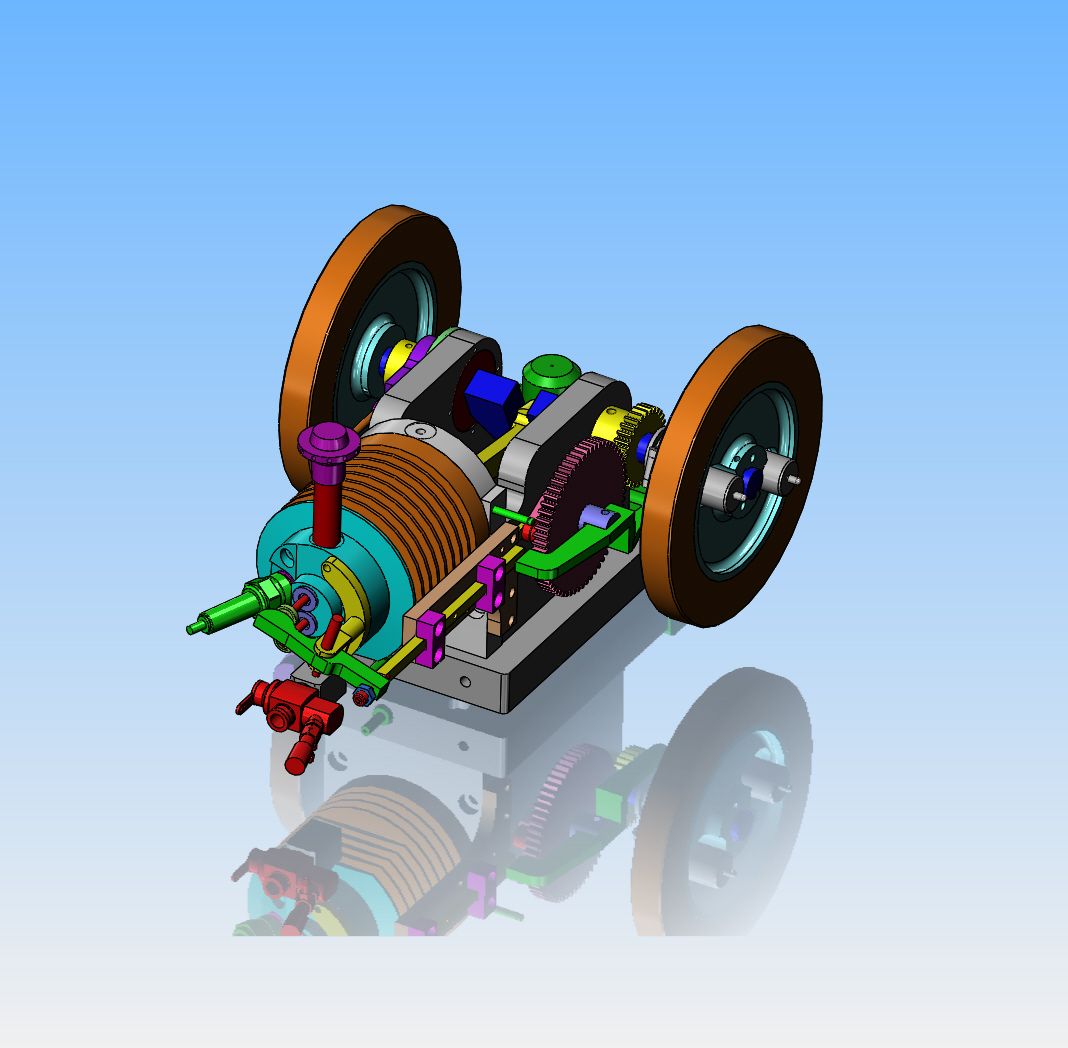

This video shows a set up whereby I can set the rpm of the governors to what it would be on the actual hit and miss engine, and see if the lockout pin in the center of my 60 tooth gear operates. This test was a definite fail----at 250 rpm, the governor weights and lockout pin didn't move at all. My conclusion is that I need a lighter governor return spring. The spring that I have in there now is one that I just picked up out of my tray full of springs and installed because it fit. Next step will be to replace it with a much lighter spring and try this test again.--Edit--Should have said 'When centrifugal force activates my governor"--Brian

Last edited: