Ken

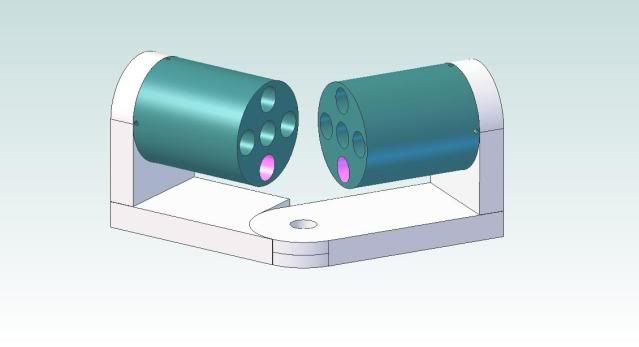

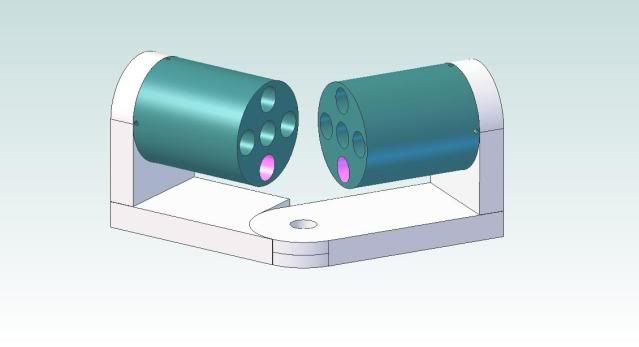

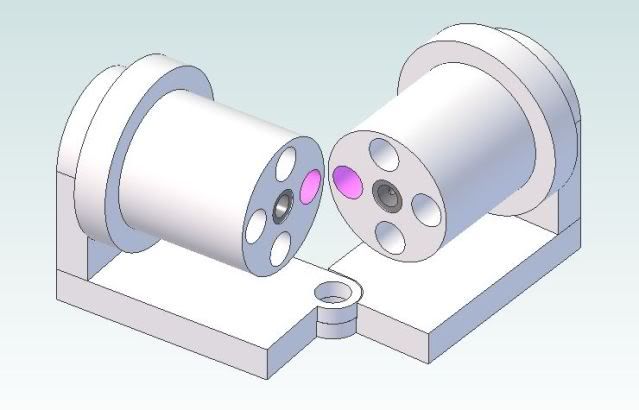

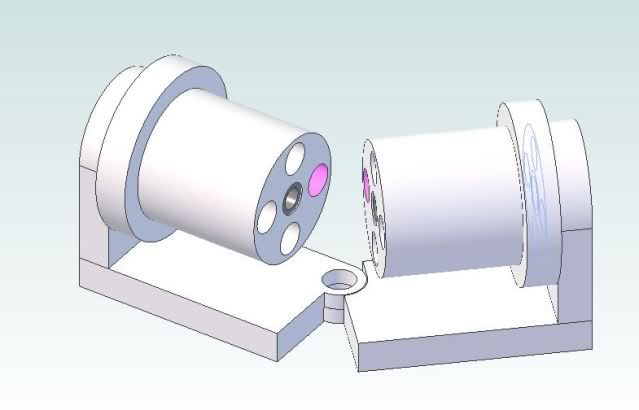

I'm not ready to build this yet but I can still think about it. I am still leaning towards a spherical joint for two reasons.

1. I have worked out a method that is extremely simple to make and they have about 270° of articulation. An example

of this joint is shown on my three cylinder opposed wobble plate engine shown here. These joints are articulating

40° but that is nowhere near the maximum available.

[ame]http://youtu.be/YR7SH5YDQGY[/ame]

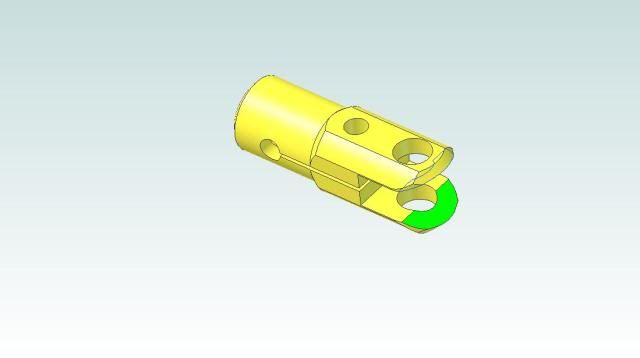

2. Half lap joints like I showed in my 3D model are easy to draw but very difficult to machine with the same accuracy and

the cantilevered pin can add a point of binding.

Knife and for joints are better balanced for thrust forces than lap joints and would be my second choice. The most important point for the joint is that it must have very little slop. To be able to change the relative angle, it must be able to articulate, but any slop will lead to alignment problems and binding.

Noitoen

I'm glad you are watching and still interested. Yes, there has been plenty of discussion of flexible elbows but as I see it, there is a difference between "flexible", (think RUBBER TUBE), and articulating, (think hinged). A fully flexible elbow could allow the two pistons to be forced out of the same plane, which screws up the geometry of this engine. If the joint only articulates, the two pistons must remain in the same plane and the two cylinders must also remain in the same plane. This is the single most important constraint in the geometry of this engine. Ken's center axis joiner assures the coplanar arrangement of the cylinders on his engine and even though he has said that it didn't change things much when he took it off, I think it was important in establishing the coplanar relationship.

Maverick

Variable volume/displacement is an important part of this design. As the engine articulates from the 90° orientation to 180°, the displacement changes from a maximum value ( depends on the bore and the PCD of the cylinder arrangement), to ZERO. If the "swinging elbow engine" can be built accurately, and is running freely at 90°, it should accelerate as the angle is increased up to some angle as the displacement is reduced. If there were absolutely no friction, it would continue to increase in speed dramatically, approaching infinity as the angle approaches 180°.

But of course friction does exist and as the displacement is reduced, so is the power and somewhere along the path, friction will begin to slow the speed and the engine will run out of power but the point where that happens is very dependent on the materials used and tolerances maintained. There have been several estimates as to what the maximum angle is that can be achieved. That could be seen by some as a challenge.

The more I think about this thing, the more anxious I am to build it. I may not have the skill or the equipment to do it justice but It is worth the time to try.