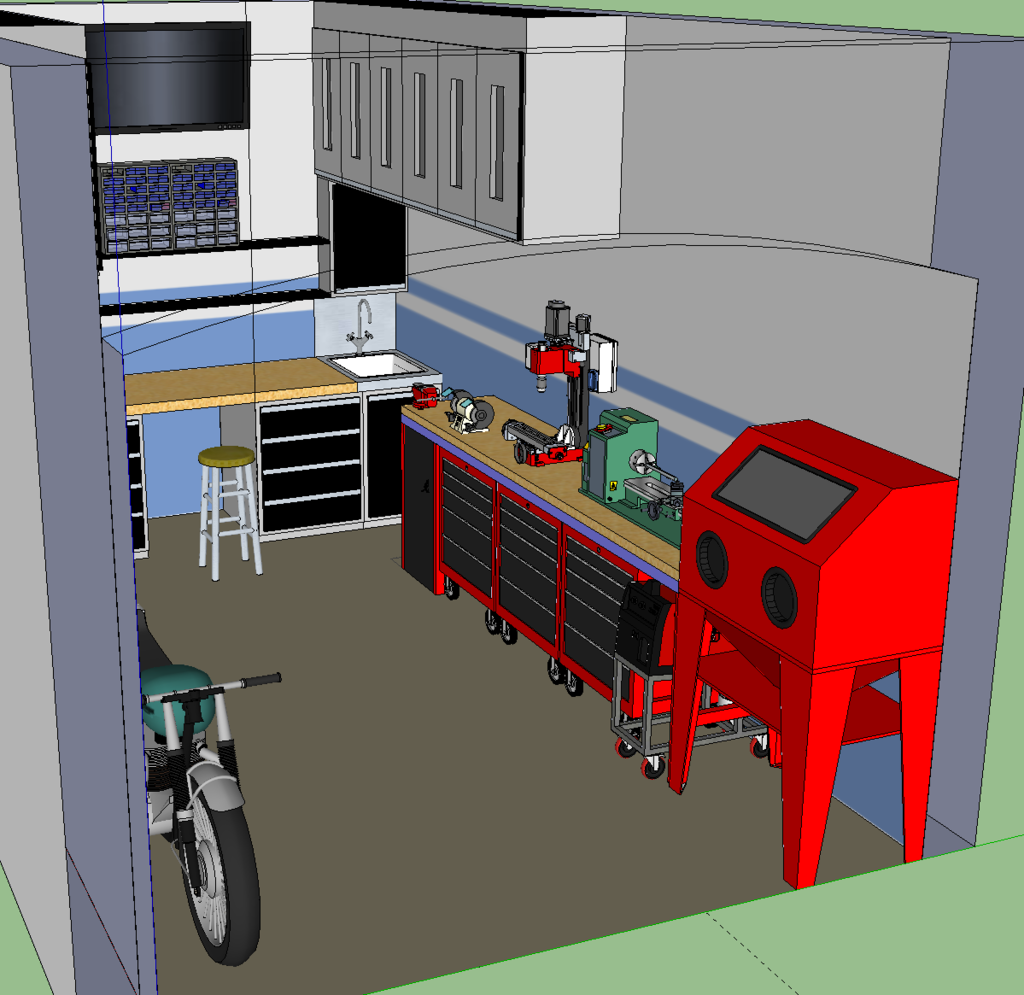

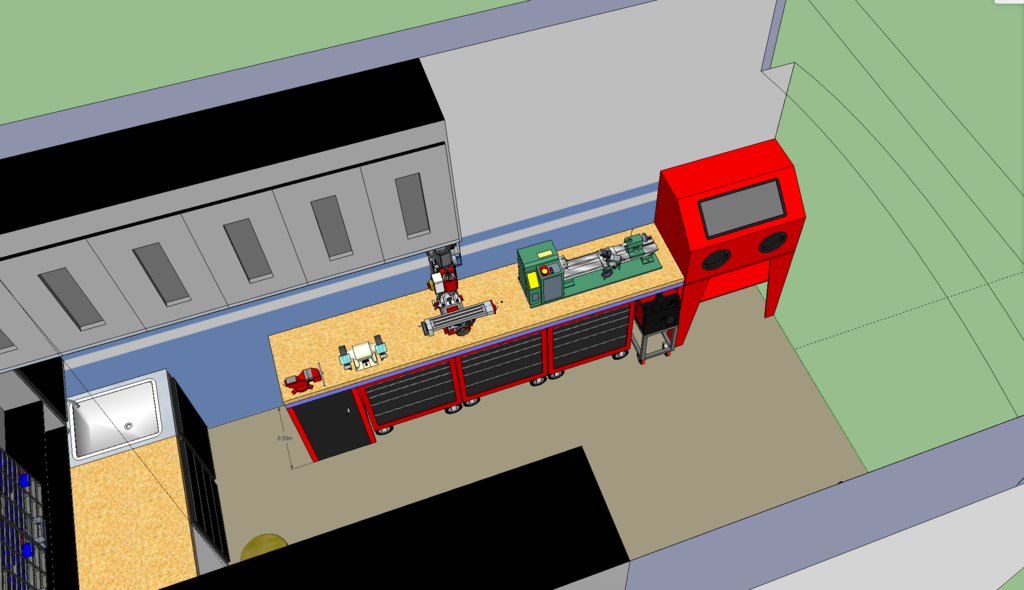

Well you see, in part one of my thoughts about getting some of those 3 in 1 I proposed was that since they have actual milling towers I could eventually detach them if I found more convenient to have two machines. I still see logic in this, but there are such amount of negative opinions in 3 in 1s that prefer to trust the wisdom here.

Best.

Ramon.

Realize that everyone has opinions that they tend to express here. Look long enough and you will find somebody happy with a 3in1. There are three major issues with 3in1s:

1. The build quality on many of them is wanting.

2. The milling capacity is often very limited.

3. Finally you often want to keep a setup on one machine function when you need to use another machine function. This can really kill process flow.

Also consider this, cheap milling machines for model engineering are a recent development. For years the model engineer survived with just a high quality lathe. Use of faceplates and milling attachments kept many a model engineer going for years.