Tim,

To make a cheapish toolpost grinder, buy a real cheap small router and hack it up to get the main motor and nose bit out. Sometimes they are separate anyway , the early B&D ones were. They have a very rigid bearing setup in the nose to take the sideways forces and get up to a fair wack in speed. You just might need to make up a collet to fit your bonded stones shaft, but they are dead easy to make. I made one for a friend and it works a dream.

It isn't worth buying expensive stuff because you only use one very occasionally, and I doubt if you would ever wear one out. It is a lot cheaper than ruining your expensive Dremels.

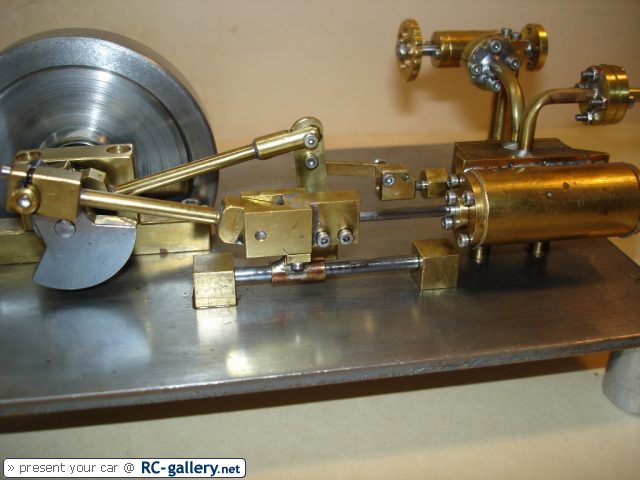

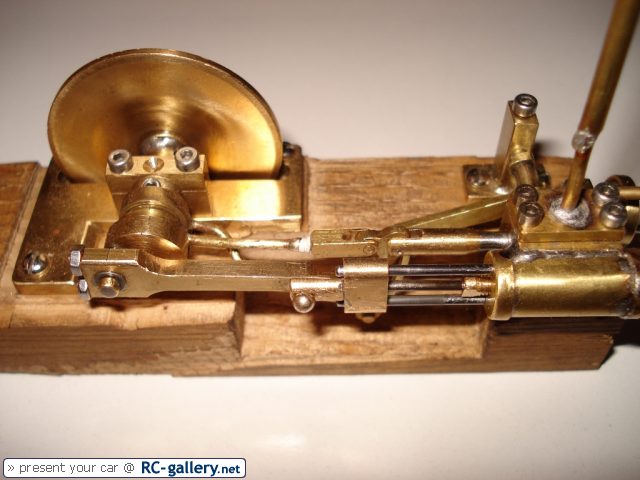

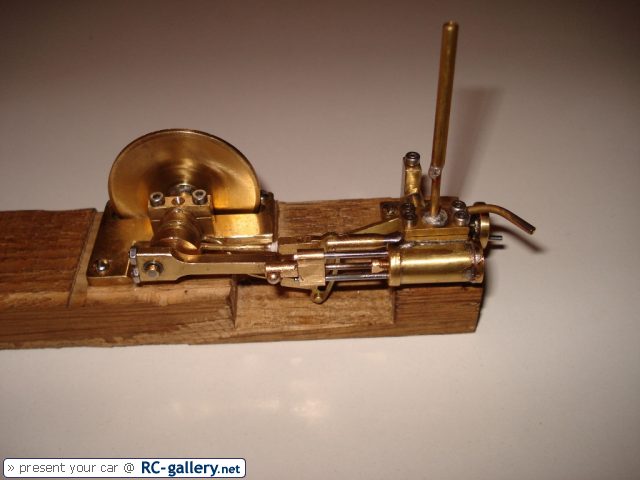

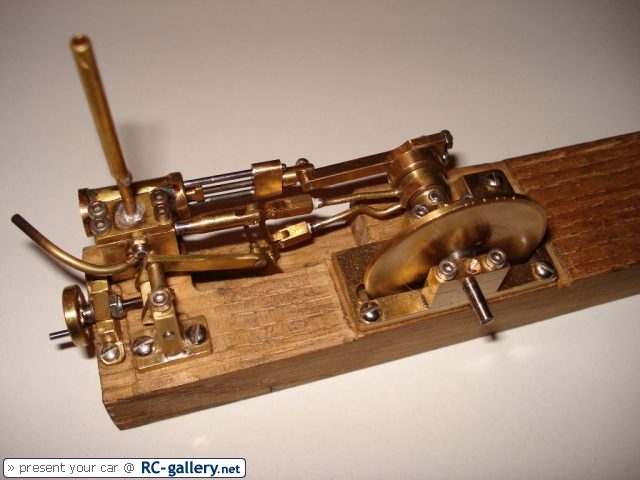

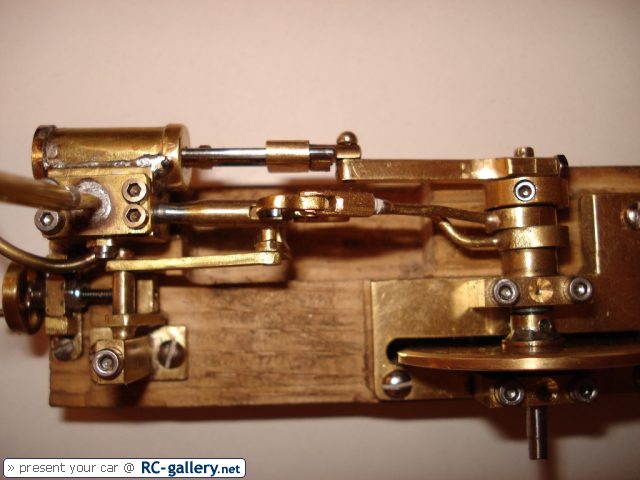

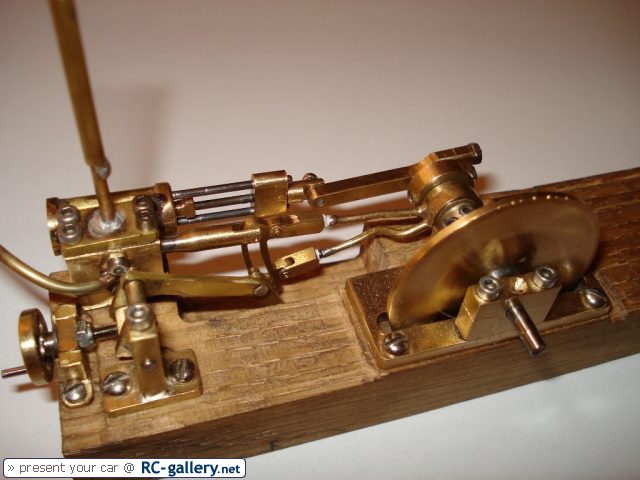

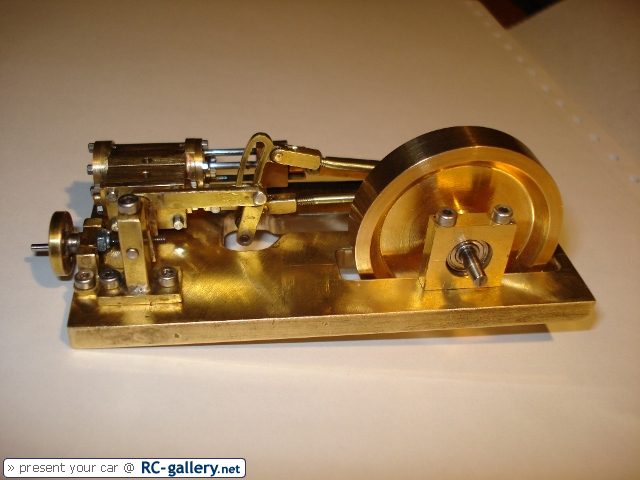

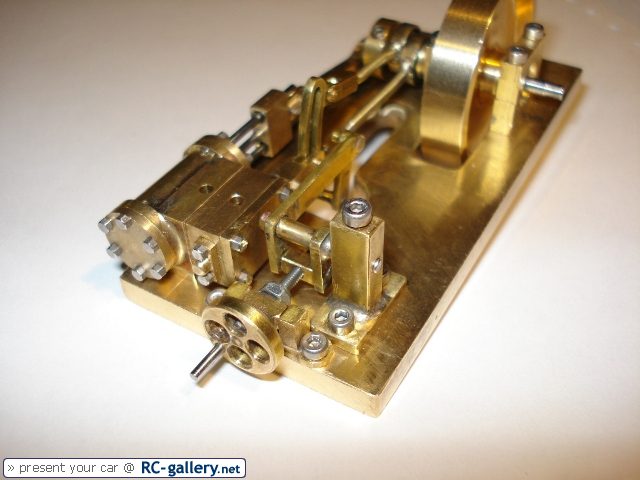

I made a banjo shaped holder that fitted around the router nose and was put into a QCT. All you need then is a fixed diamond dresser to trim the stone parallel to the lathe bed.

If you have compressed air, I have seen cheap pneumatic die grinders used to good effect as a toolpost grinder, again, these have a well supported nose, designed for sideways pressures, also the pressure can be reduced for slower running with a larger outside grinding wheel. Not that you use a lot of sideways force, in fact there should hardly be any, it is just the rigidity you are after, usually lacking in small hand held mini drills.

You are supposed to run the stone in opposite directions when doing either internal or external grinding, my commercial grinder runs in both directions by flicking a switch. You can get away with it by running the lathe chuck in reverse.

John