Deanofid said:Looks nice all set in place on the bearing block, Joe.

Where did you get that cute distributor?

Dean

"Hi Dean

Got it from Mike Neal at MJN. I'm not sure if he's still in business, I've read some horror stories regarding trying to get ahold of him lately. If so, too bad, it's a nice piece of kit.

Joe"

I tried to get a coil from MJN last year and he sent my check back (it didn't bounce, he just didn't want to be bothered)

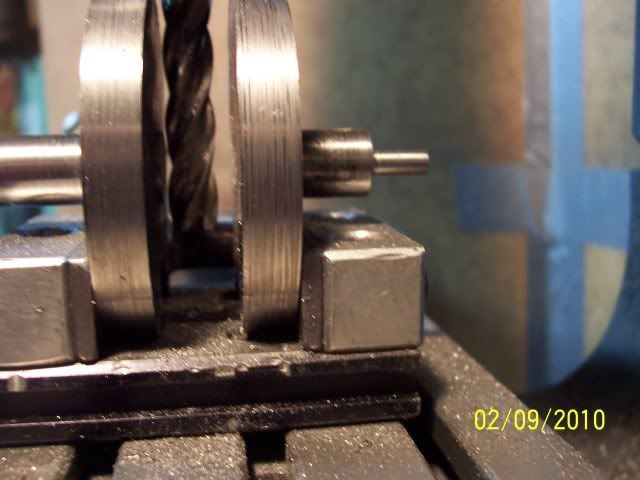

CNC Machine

http://www.cncengines.com/index.html

Roy said he is going to start carring them

Tony