Hello all!

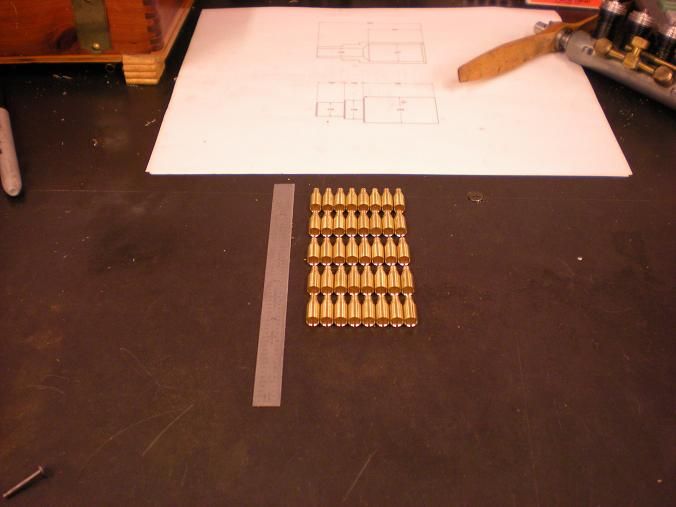

Now that the Zanesville show is behind me, I can get back to the V8. I started on some valve cages today. I made the blanks in the chuck and then switched to the collet to machine the top of the cages. I have 5 heads to trim out so I had to make 40 pieces. Yikes!

Now that the Zanesville show is behind me, I can get back to the V8. I started on some valve cages today. I made the blanks in the chuck and then switched to the collet to machine the top of the cages. I have 5 heads to trim out so I had to make 40 pieces. Yikes!