You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Show Us Your Lathe

- Thread starter rake60

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Hi

Glad to be on someone else’s thread. My lathe is still on the floor. Sometimes I envy you guys, South Africa is a vibrant Thirld World country… I don’t know where its economy comes from. I just made the long trip to Durban and came back with the best lathe I could find. Looking at it on the floor… The “intermediate gear” gear is plastic … major dissapointment … why? If I would have known I could have dealt with the suppliers, like I’ll only buy the thing together with a box of 10 plastic gears. Now I’ll have to go to the ends of the Earth to find a spare.

Ant

Glad to be on someone else’s thread. My lathe is still on the floor. Sometimes I envy you guys, South Africa is a vibrant Thirld World country… I don’t know where its economy comes from. I just made the long trip to Durban and came back with the best lathe I could find. Looking at it on the floor… The “intermediate gear” gear is plastic … major dissapointment … why? If I would have known I could have dealt with the suppliers, like I’ll only buy the thing together with a box of 10 plastic gears. Now I’ll have to go to the ends of the Earth to find a spare.

Ant

Ant: I think that most lathes that use a plastic gear, use it as a shear pin. They are assuming that inexperienced people will be using the lathe and it is better to break a plastic gear than to trash the lathe. If you are confident in your capabilities, I am sure that you could get a metal gear to replace it. Probably not from the lathe company but from a gear company.

Tin Falcon

Well-Known Member

- Joined

- Jul 9, 2007

- Messages

- 7,207

- Reaction score

- 788

rake60 said:I started this thread on July 10, 2007.

This web site was exactly 2 days old at that time.

Now I think it was a bad idea.

Tool envy is a terrible thing to live with!

Nice toys guys! Thm:

Rick

Hear Hear you are so right.

Ant You should have some safety easy to replace easily broken part in the system keep a spare or two on hand. If there is not a weak point to break lots of things could bend and cause real havoc.

Tin

Thad Swarfburn III

Well-Known Member

Here's my Emco Compact 8. Bought it a few months back. Has been run hard and put away wet. It was full of brass swarf when I got it, and the belt was on wrong. I had to make a new toolpost for it (out of 4340) as some rough pr**k had turned the clamping screws hard enough to distort the old one. Haven't made anything of value yet - still gathering tooling. I've made a faceplate from 6000 series ally, and a cast iron adaptor to hold a Chinese 100mm 4-jaw. Still need parting and boring tools. The lead screw is bent (I suspect from being crudely moved) and causes "ribbing" in horizontal cuts. This will be straightened. I'll also take the bed into work to put on our CMM and grind it if it's really bad.

On that note, can anyone tell me the reason for the tailstock being on a separate set of v-ways?

My neighbour's got the same lathe in fine condition (he paid 4 times what I did) and I keep lusting after his milling attachment.

Keep posting these, guys. I'm enjoying seeing some of the older iron. Those Monarchs are sweet!

Matt

- Joined

- Jun 4, 2008

- Messages

- 3,285

- Reaction score

- 630

All the lathes I've seen have separate ways for the tailstock and carriage. Since the carriage will move a lot more than the tailstock over time, I imagine that it's to keep wear on the carriage ways from taking the tailstock off center.On that note, can anyone tell me the reason for the tailstock being on a separate set of v-ways?

Tin Falcon

Well-Known Member

- Joined

- Jul 9, 2007

- Messages

- 7,207

- Reaction score

- 788

DIYM cute little lathe what brand is it cant say it is under powered.!!!

Tin

Tin

R

RobWilson

Guest

Looking good Diymania......... Thm:

Regards Rob

Regards Rob

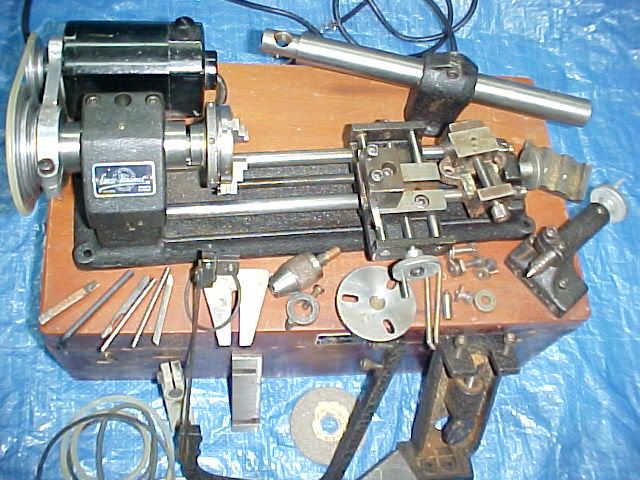

Diymania said:I figure its my turn to join this thread with my rather useless little lathe...

I wouldn't call a Unimat "useless". There has been a lot of top end work done with these.

Looking better too, now that you have it out of that "pile-o-hazards"..

Dean

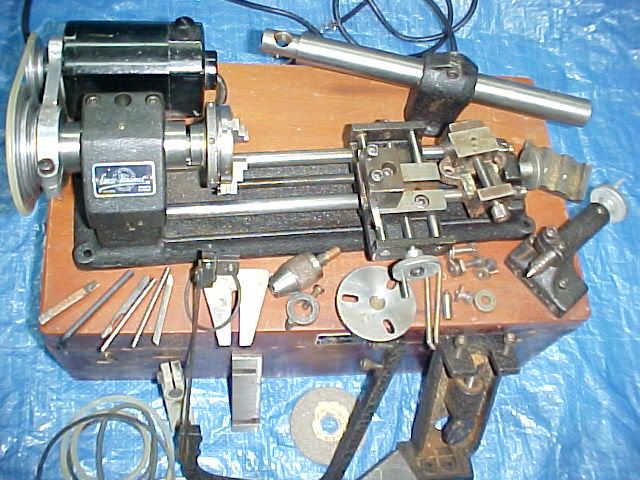

Nice looking lathe, makes me want to go lathe hunting and I found this one, another yard sale, Lathe Nut

rake60 said:I've had a few hobby lathes in my basement.

The one I have now is this Grizzly 9 X 19

It's the same machine sold by Harbor Freight as a 9 X 20

Grizzly measures to a live center vs. a dead center.

Their made in China!!! :shock: Any REAL machinist knows that means

their nothing but JUNK! Let's keep that mith alive to keep the prices in

line. :wink: A better compound clamp a tweak where and there and I

have NO complaints!!!! It's been a great little machine for the price.

macona

Well-Known Member

- Joined

- Sep 20, 2007

- Messages

- 112

- Reaction score

- 3

Got my little Hercus making chips.

Here is a video of it cutting 1/2"-13 threads in 6061... At 2000RPM.

It can go faster than that though...

http://www.youtube.com/v/YKb2g5xalEk&hl=en&fs=1&rel=0

I thought I had posted the machine earlier when I got it, guess not.

Hercus Compulathe, made in 86. Main board was fried so I have spend the past 4 months or so retrofitting it. Was DC brushed servo with resolver feedback. 80w motors on each axis. I have replaced them with Mitsubishi Brushless servos, 400w on the carriage and 200w on the cross slide. Now does 380ipm.

Here is a video of it cutting 1/2"-13 threads in 6061... At 2000RPM.

It can go faster than that though...

http://www.youtube.com/v/YKb2g5xalEk&hl=en&fs=1&rel=0

I thought I had posted the machine earlier when I got it, guess not.

Hercus Compulathe, made in 86. Main board was fried so I have spend the past 4 months or so retrofitting it. Was DC brushed servo with resolver feedback. 80w motors on each axis. I have replaced them with Mitsubishi Brushless servos, 400w on the carriage and 200w on the cross slide. Now does 380ipm.

Similar threads

- Replies

- 209

- Views

- 36K