Holescreek said:

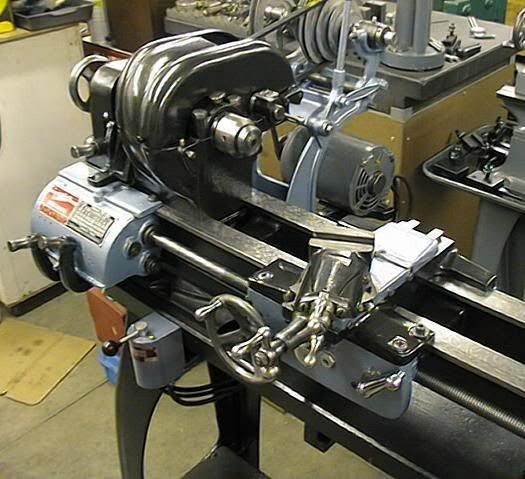

I found the Cataract locally on Craigslist.... I need this lathe like a hole in the head. I already have the Atlas taking up valuable space. I have a soft spot for old machinery that still has so much potential.

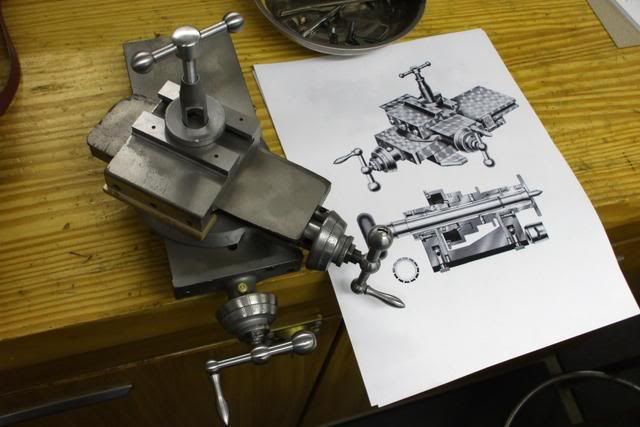

That feeling is well known here in HMEM. Quite a few machines here have been resurrected from the dead to go onto live healthy, happy & productive lives. Due to space considerations I can't get anything with the bed length this has but it's the right idea as to type. Nice and basic with no bells & whistles, just like the typical watchmaker's lathe.

Of course, if I were to follow through with the watchmaker's lathe comparison, then I'd think it should be given a very heavy nickel or chrome plate finish.

Kluge, I was stationed in HI at Kaneohe MCAS from '78-81. I still don't want to go back, much to my wife's dismay. Too much paradise at a young age!

There've been a few changes. Barbers Point NAS is closed (1999) and the VP squadrons fly out of Kaneohe now, still with the Orions but soon to upgrade to Poseidons. The ANG is still flying F-15s but will get F-22s in the next year or two, and the AF is flying C-141s (or are they C-5As?) and the occasional tanker.

The Corps practices amphibious landings at Bellows (now closed ... kind of); the state government is still just as messed up if not more so; you can once again get anything you want on Hotel St, you just have to look harder; we still love the 'Bows (It's an act of treason not to.

); no one knows which direction North is; and 'da kine' is still a noun, verb and adjective. Maybe adverb too, I'm not sure.

I moved here in 2000 from PA completely blind. I'd never been here before but I was told it's both senior and veteran friendly ... both of which have since gone downhill due to budget problems. My residence now is a tiny studio on the Waianae (Leeward) Coast inside the tsunami zone but with direct access to the ocean.

As to too much paradise ... I'm pretty sure the statute of limitations has run out by now. :big:

Best regards,

KLudge