Maryak

Well-Known Member

- Joined

- Sep 12, 2008

- Messages

- 4,990

- Reaction score

- 77

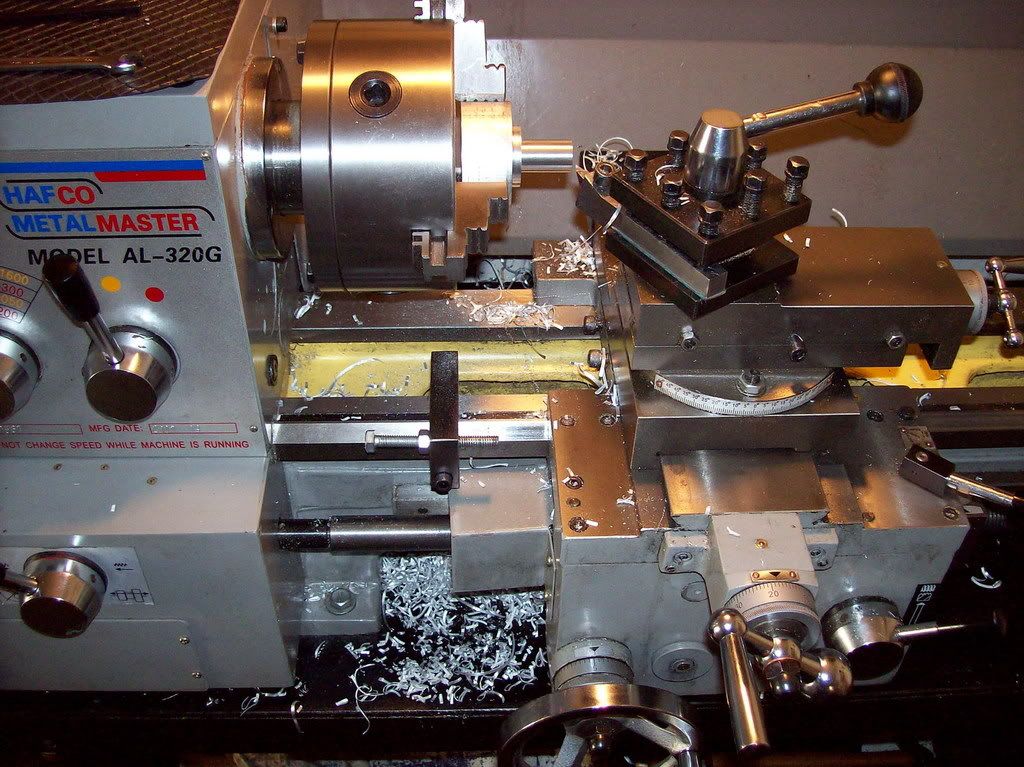

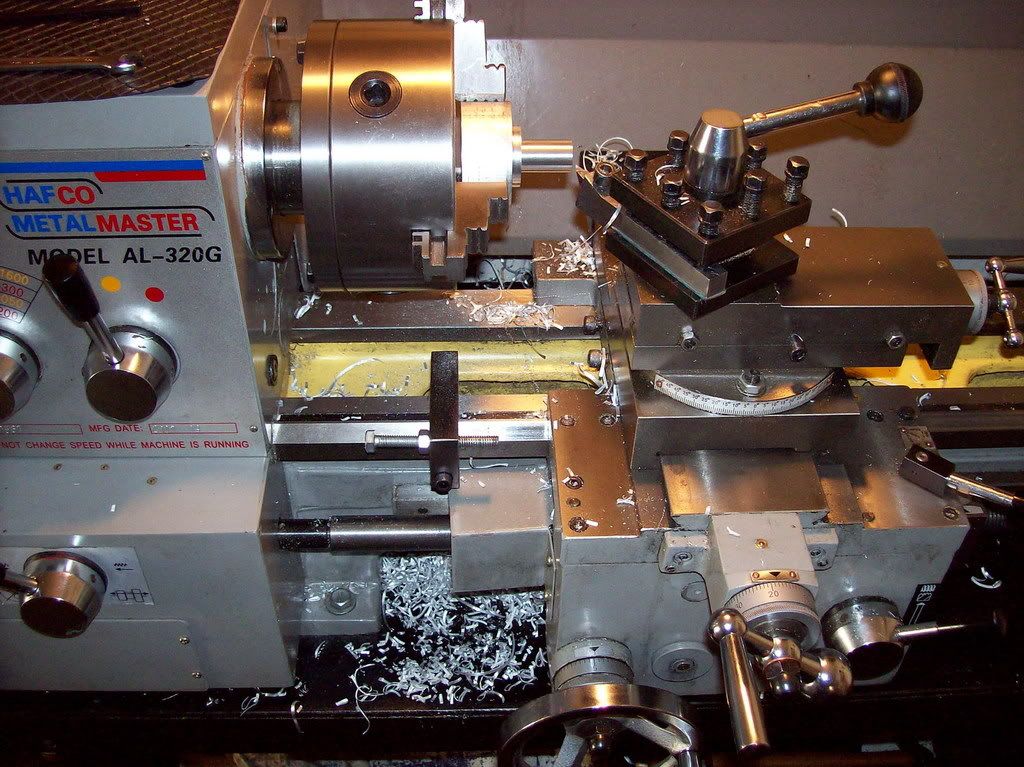

Below is a photo of my lathe - Made in China and is rebadged to suit the importer into whatever country eg Colchester in the UK and Hare & Forbes in Oz. Probably the only thing in Oz not made in China these days is me, I'm a pommy immigrant from age 13.

Its a 6" Eng 12" USA with 2ft, 600mm between centres came with everything,2 chucks, faceplate, steadies, centres etc. speed range 60-1800, (frightened sh 1 T out of me with the 4 jaw on!!!). What does it lack, a gap bed and a screw cutting gear box. Still when you think about it for as often as threads require machining, change wheels both metric and imperial are not too much of a hassle. :

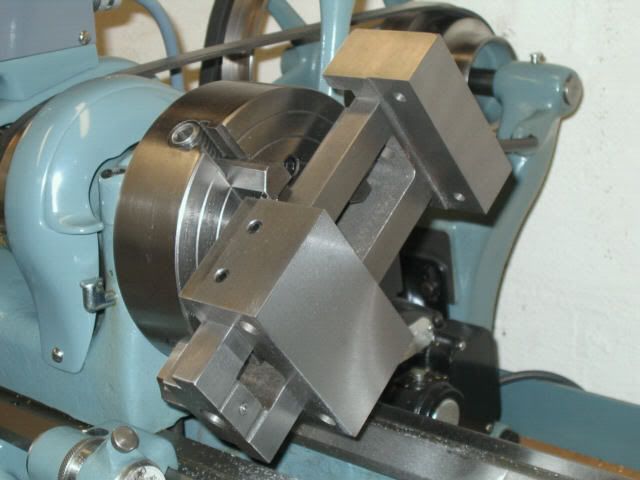

Whilst on the subject, I have been around lathes for some 45 years now and in Issue 140 of Model Engineers Workshop was an article by the ever publishing Harold Hall covering a carriage stop. Never used one!

What the hell it's not much work so I will make one. Took under 2 hours and he was absolutely correct it is one of the most useful gizmos I have ever made and after less than a week I wonder how I had the insanity to challenge myself for accuracy all those years, when this little gem makes it Oh So Simple.

Thank you Mr Hall and MEW. :- :bow:

Its a 6" Eng 12" USA with 2ft, 600mm between centres came with everything,2 chucks, faceplate, steadies, centres etc. speed range 60-1800, (frightened sh 1 T out of me with the 4 jaw on!!!). What does it lack, a gap bed and a screw cutting gear box. Still when you think about it for as often as threads require machining, change wheels both metric and imperial are not too much of a hassle. :

Whilst on the subject, I have been around lathes for some 45 years now and in Issue 140 of Model Engineers Workshop was an article by the ever publishing Harold Hall covering a carriage stop. Never used one!

What the hell it's not much work so I will make one. Took under 2 hours and he was absolutely correct it is one of the most useful gizmos I have ever made and after less than a week I wonder how I had the insanity to challenge myself for accuracy all those years, when this little gem makes it Oh So Simple.

Thank you Mr Hall and MEW. :- :bow: