You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Show Us Your Lathe

- Thread starter rake60

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

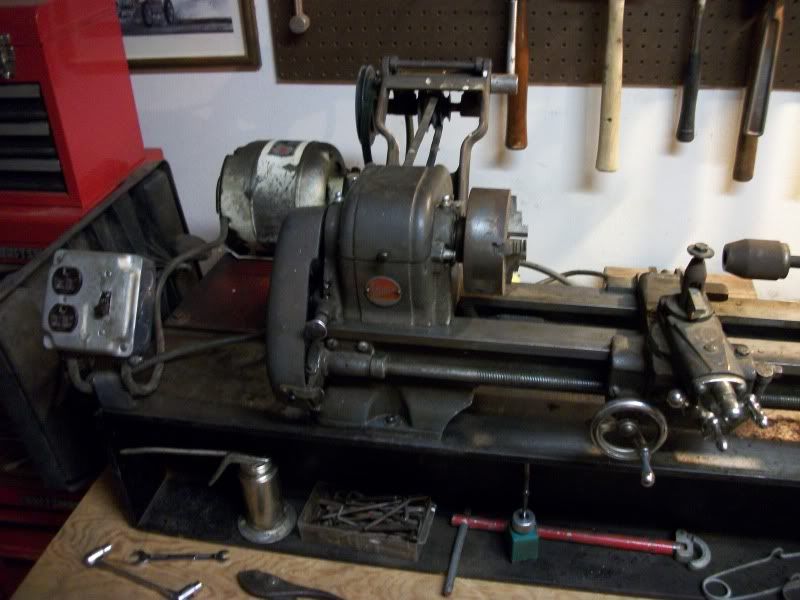

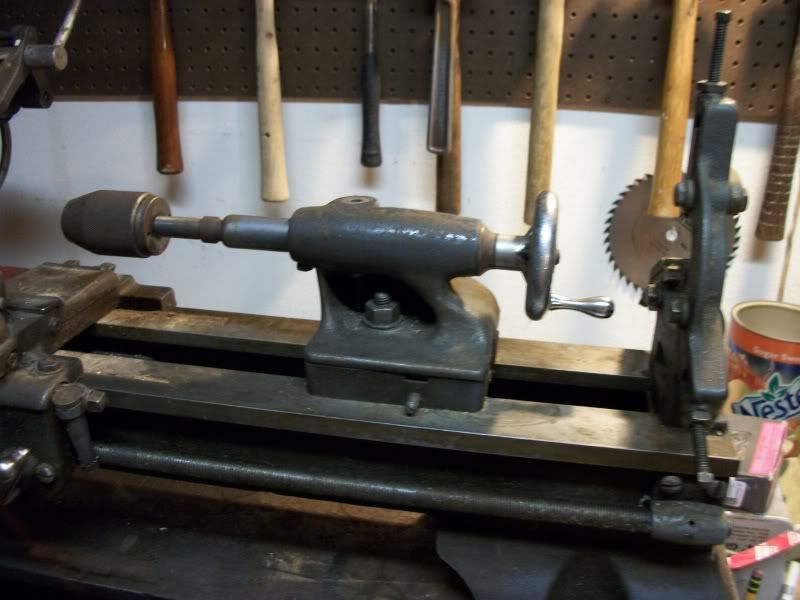

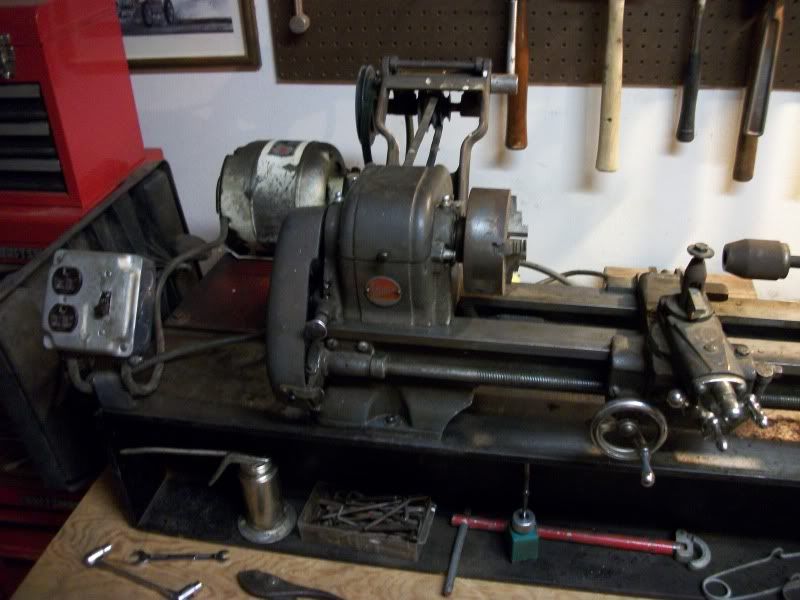

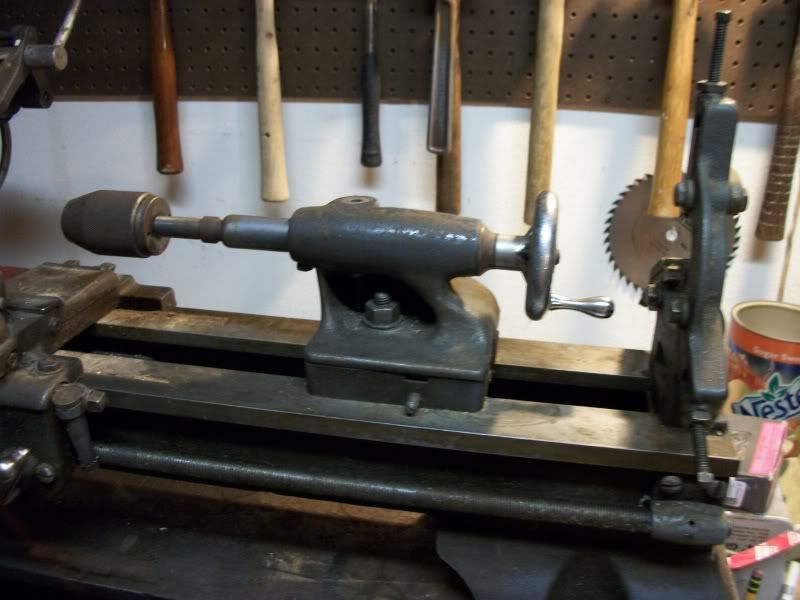

An Atlas metal lathe I inheirited from my late father last May:

Longview:

I just got it reassembled in my garage but don't know if I have it right, but it seems to work!

I do have to find a narrower belt for the main motor belt. The transmission belt is old but stays where you set it. The main drive belt keeps slipping off, but it is new and too wide.

Longview:

I just got it reassembled in my garage but don't know if I have it right, but it seems to work!

I do have to find a narrower belt for the main motor belt. The transmission belt is old but stays where you set it. The main drive belt keeps slipping off, but it is new and too wide.

B-N,

I loved my old Atlas 10F, and up to now, I did a lot of my best work using it.

The belt can be a problem, as you have to disassemble the whole spindle just to change it. I changed mine to a Redthane tubing one, joined by heat at the ends, so it was just a matter of cutting the old v belt off and threading the circular belt on, and then heat joining the ends. You can do the same sort of thing with link belting. It might be a touch expensive for the initial outlay, but that is offset by not having the trauma of stripping the head down.

Very nice lathe BTW.

Bogs

I loved my old Atlas 10F, and up to now, I did a lot of my best work using it.

The belt can be a problem, as you have to disassemble the whole spindle just to change it. I changed mine to a Redthane tubing one, joined by heat at the ends, so it was just a matter of cutting the old v belt off and threading the circular belt on, and then heat joining the ends. You can do the same sort of thing with link belting. It might be a touch expensive for the initial outlay, but that is offset by not having the trauma of stripping the head down.

Very nice lathe BTW.

Bogs

- Joined

- Nov 14, 2009

- Messages

- 675

- Reaction score

- 104

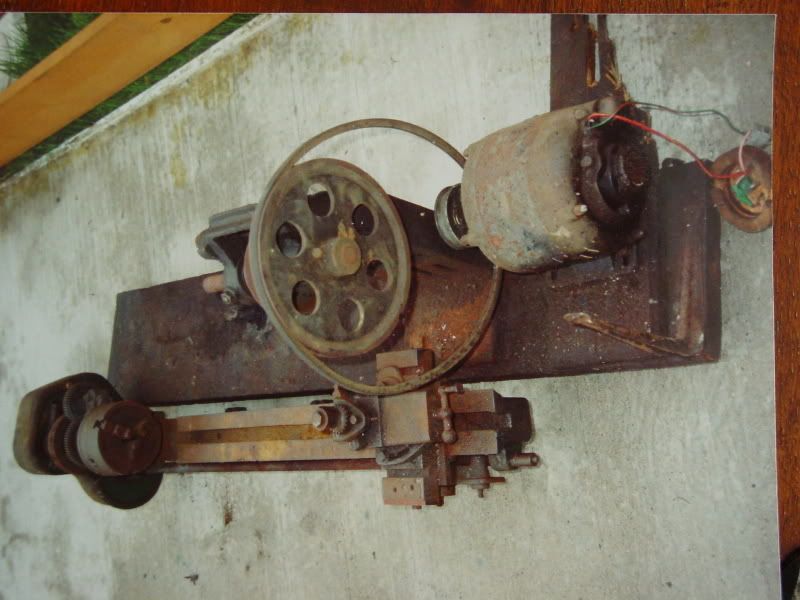

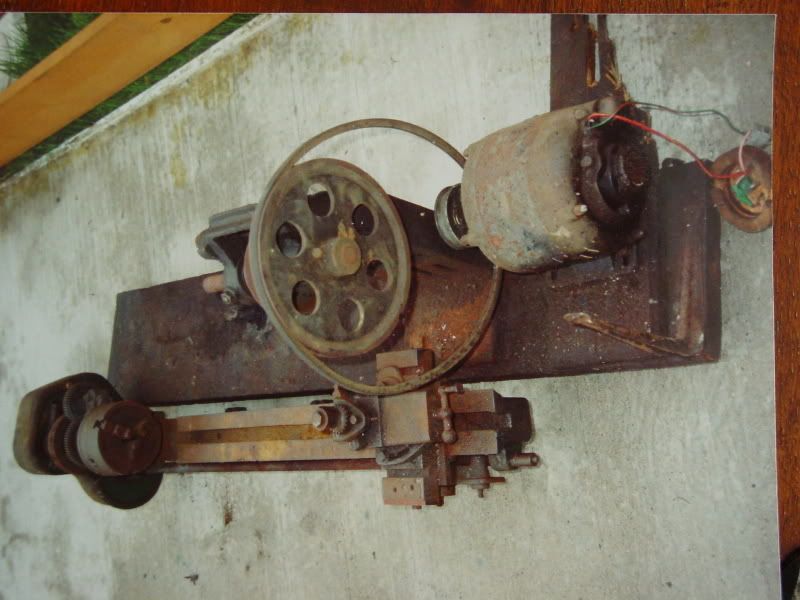

This is my 1st lathe,my boss got it from some where,so asked if I could have it,built my clock movement with it,sold it on for an Atlas then sold that for a Myford super 7

Before

After

Don

Before

After

Don

good looking lathes fellows, I have a six inch Atlas, love it and sure would love to have that Myford, you did a great job bring him back from the dead, I tell my wife it not what it is but what it can be, that is a good example, glad for you fellows, Laht Nut

around

Junior Member

I have just finished refurbishing a 1972 Boxford AUDII. A complete strip down, cleaning, rebuild of several parts, rewiring and finally refinishing. Time to retire my 1988 Taiwanese 9X20!

Cheers,

Adrian

Cheers,

Adrian

What a lovely job you have done of that Adrian, it now looks too good to be used.

That range of Boxford lathes really are almost bombproof, and were the mainstay of most school and college workshops. So plenty of spares (new and old) to be had.

For the price you can still pick them up for, they are a bargain to be had. Around here, they go at the local scrappies for about 400 squid (ex college and schools clearance), so a little work (or a lot) as you have done, there is no reason not to have a reasonable sized lathe in your shop.

Wonderful work.

Bogs

That range of Boxford lathes really are almost bombproof, and were the mainstay of most school and college workshops. So plenty of spares (new and old) to be had.

For the price you can still pick them up for, they are a bargain to be had. Around here, they go at the local scrappies for about 400 squid (ex college and schools clearance), so a little work (or a lot) as you have done, there is no reason not to have a reasonable sized lathe in your shop.

Wonderful work.

Bogs

barney_leadhead

Member

- Joined

- Apr 26, 2010

- Messages

- 17

- Reaction score

- 0

WOW - It looks like it has just been delivered from the factory! 8)

I am just at the last steps and details of the restoration of my new lathe, guess what machine it is ;D

Here's a picture how i bought it (almost 2 years ago now)

And what it looked like 3 weeks ago (when i noticed the bed needs some grinding to get in a good shape again; there was 5/100 mm difference on the square guide and thats too much for mee...)

Cheers

Florian

Here's a picture how i bought it (almost 2 years ago now)

And what it looked like 3 weeks ago (when i noticed the bed needs some grinding to get in a good shape again; there was 5/100 mm difference on the square guide and thats too much for mee...)

Cheers

Florian

zeeprogrammer

Well-Known Member

- Joined

- Mar 14, 2009

- Messages

- 3,362

- Reaction score

- 13

Beautiful job!

Yours? Otherwise I have no idea. ;D

Florian said:guess what machine it is

Yours? Otherwise I have no idea. ;D

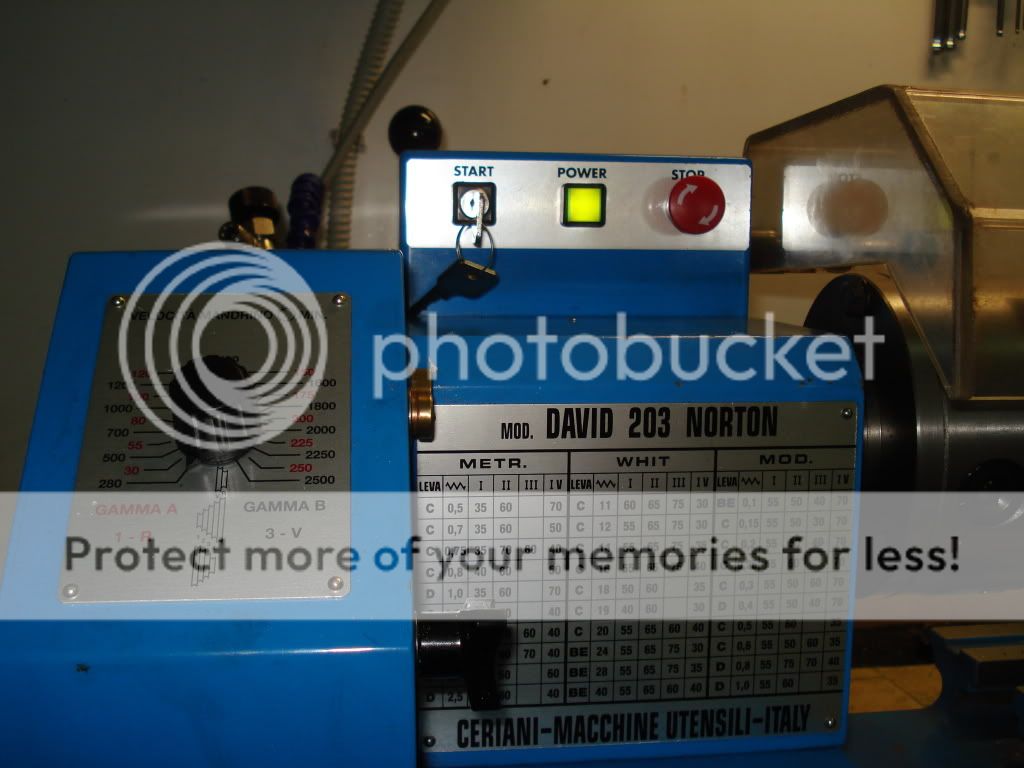

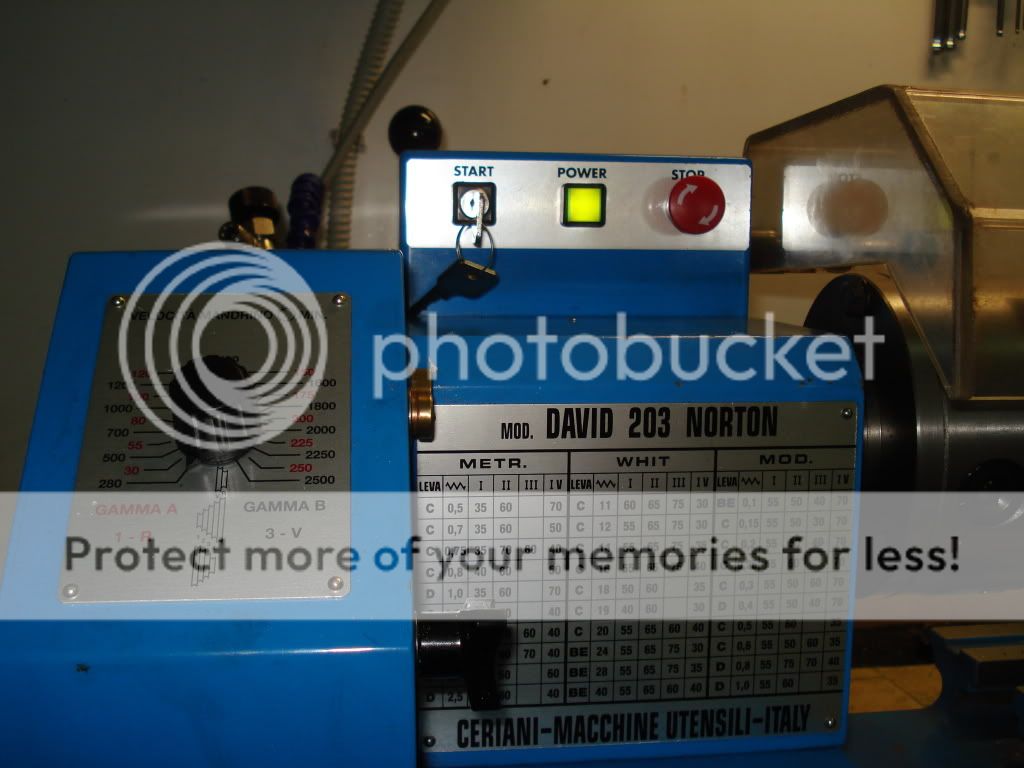

I'll try to describe my David as someone requested... ;D

The bed, in stabilized cast iron is very rigid. It is very well machined and free of any flaw

Headstock is an Enbloc, well sized and machined with accuracy.

Chuck spindle: The chuck spindle rotates on adjustable TIMKEN taper roller bearings and really free and without any noise.

Drive system: Machine drive is obtained by a set of pulleys and V-belts and mine had a modification now It has a inverter control system so I use just two mechanical combination, slow and high position, and the infinite variation by the potentiometer.

The automatic work feeds is really useful. I requested to Ceriani factory a little modification like the reversing gear system so Im capable to do a reverse treading!!

Carriage: The carriage with apron is well proportioned and slides on dove tail guide ways protected by oil scrapers; it is fitted with a self-adjusting jib. Traverses take place by means of a hand wheel and rack gear.

Saddles: The saddles are sturdy and easy to adjust, equipped with precision screws mounted on ball bearings and with well engraved adjustable vernier. The adjustable tailstock is also equipped with a adjustable vernier and it turns, unfortunately, counterclockwise. I contacted Ceriani brothers several times suggesting the modification of that rotation sense. The quick blocking happens, without any hesitation, through a comfortable lever.

The pivoting protection screen and the carter door are protected by micro switches

I had also the two chuck, a three and four jaws, mounted on the back plates by Ceriani. I adapted another back plate on the 5C chuck . Now I can change chucks without losing precision. I didnt measured the backlash but the resulting works done until now seems To be really precise.

Compared to other lathes of the same category I preferred that lathe due to the 32 mm spindle hole

and his relative light weight, 80kg a really bench top lathe, instead of 180kg for a similar lathe.

and his relative light weight, 80kg a really bench top lathe, instead of 180kg for a similar lathe.

The bed, in stabilized cast iron is very rigid. It is very well machined and free of any flaw

Headstock is an Enbloc, well sized and machined with accuracy.

Chuck spindle: The chuck spindle rotates on adjustable TIMKEN taper roller bearings and really free and without any noise.

Drive system: Machine drive is obtained by a set of pulleys and V-belts and mine had a modification now It has a inverter control system so I use just two mechanical combination, slow and high position, and the infinite variation by the potentiometer.

The automatic work feeds is really useful. I requested to Ceriani factory a little modification like the reversing gear system so Im capable to do a reverse treading!!

Carriage: The carriage with apron is well proportioned and slides on dove tail guide ways protected by oil scrapers; it is fitted with a self-adjusting jib. Traverses take place by means of a hand wheel and rack gear.

Saddles: The saddles are sturdy and easy to adjust, equipped with precision screws mounted on ball bearings and with well engraved adjustable vernier. The adjustable tailstock is also equipped with a adjustable vernier and it turns, unfortunately, counterclockwise. I contacted Ceriani brothers several times suggesting the modification of that rotation sense. The quick blocking happens, without any hesitation, through a comfortable lever.

The pivoting protection screen and the carter door are protected by micro switches

I had also the two chuck, a three and four jaws, mounted on the back plates by Ceriani. I adapted another back plate on the 5C chuck . Now I can change chucks without losing precision. I didnt measured the backlash but the resulting works done until now seems To be really precise.

Compared to other lathes of the same category I preferred that lathe due to the 32 mm spindle hole

mariolucchini

Member

- Joined

- Sep 15, 2009

- Messages

- 19

- Reaction score

- 0

I'm a newby to this forum and I'm showing the lathes I use.....I work mainly in micromechanics and these little machines are all I need for the moment....

First the most discussed Emco Unimat 3....some love it, others hate it.....its given me faithfull service for more than 35 years....

Then there's the Boley F-1......filthy precise with all its original box of accesories...

And then the WW Lorch 7, which I got for very little $$$, and overhauled completely...mighty precise machine too, and what's best is that all the Boley's accesories fit right in....

Thanks for looking....

Mario

First the most discussed Emco Unimat 3....some love it, others hate it.....its given me faithfull service for more than 35 years....

Then there's the Boley F-1......filthy precise with all its original box of accesories...

And then the WW Lorch 7, which I got for very little $$$, and overhauled completely...mighty precise machine too, and what's best is that all the Boley's accesories fit right in....

Thanks for looking....

Mario

Similar threads

- Replies

- 209

- Views

- 35K