You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Shop Tricks for Disabilities

- Thread starter MachineTom

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Tom great mods all round.

Although a wheely not an accident but Neuro muscular problem. I can while using a bench to lean on but only for short periods. Its through this I climb onto a modified draughtmans stool I put 100mm wheels on the ali base and I push the wheelchair out of the small workshop and then I can wiggle/move around all my machines. Mostly woodworking and as the stool is a gas lift I have to set the height first then climb onto it.

Although a wheely not an accident but Neuro muscular problem. I can while using a bench to lean on but only for short periods. Its through this I climb onto a modified draughtmans stool I put 100mm wheels on the ali base and I push the wheelchair out of the small workshop and then I can wiggle/move around all my machines. Mostly woodworking and as the stool is a gas lift I have to set the height first then climb onto it.

My kids stir me for being short, so I think I'd need a step ladder to climb on that chair Ray, and I'm pretty sure I'd also immediately fall off!

Hmmm, motorised chair, there's a thought! On a more serious note, the fortitude of some you guys really do make me feel bad when I whinge about trivial things, quite amazing and admirable how you just don't let things hold you back.

cheers mate, Ian

Hmmm, motorised chair, there's a thought! On a more serious note, the fortitude of some you guys really do make me feel bad when I whinge about trivial things, quite amazing and admirable how you just don't let things hold you back.

cheers mate, Ian

user 13961

New Member

- Joined

- Jan 31, 2013

- Messages

- 2

- Reaction score

- 0

Hi Tom

I am just starting with my home machine shop.

I am inspired by how organised, clean and versatile your adaptation seem to make it. I have been working with people with disabillities and modifications and adaptations to equipment in vanuatu.

Thanks for the inspiration

Frank

I am just starting with my home machine shop.

I am inspired by how organised, clean and versatile your adaptation seem to make it. I have been working with people with disabillities and modifications and adaptations to equipment in vanuatu.

Thanks for the inspiration

Frank

Alec Ryals

Well-Known Member

- Joined

- May 3, 2012

- Messages

- 154

- Reaction score

- 81

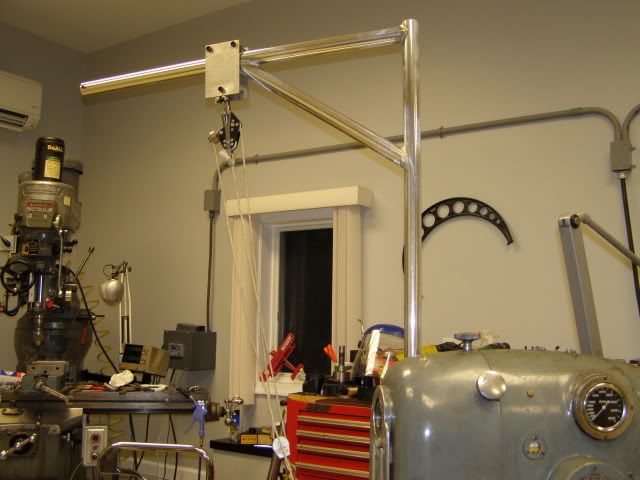

On the lathe a wall mount for a TV supports an old Bridgeport tool holder, the box on the wall is all lathe tools

Then swings out of the way

This lift is bolted to the back of the lathe, used to swing the chucks and work pieces for the lathe

Yeah the BB pillowblocks were overkill, but it sure spins nice

Heres a chuck with the lift bracket, the block and tackle is quick it needs to lift about 40 lbs is all

To lift heavy stuff there is a 4K cherry picker, this is an invalid lift 300lbs at the hook, overhung +18" safe at 50lbs, battery powered

Thanks for looking, I hope someone can use these idea's for themselves.

Tom

Wow this Shop is Great ! I'm in a wheel chair for 25 years now and have got back into machining the last 6 years hence i had my own business and bought a rebuilt a South Bend 10 & 9 inch lathes a shaper and a small Clausing mill with a Bridgeport M-head mounted on it all work great, I build steam and gas engines etc Keep Up Th Great Work

Thank You

Alec Ryals

- Joined

- Oct 20, 2010

- Messages

- 913

- Reaction score

- 132

Yeah, fifteen years last august for me. It seems this last year my age has caught up to my condition. But I will keep fighting until I lose, whenever that is.

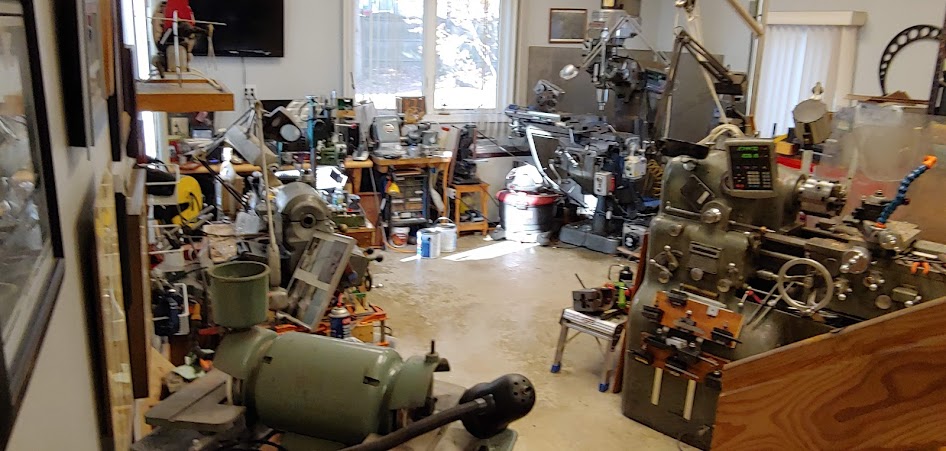

Thanks for the kind comments regarding the shop. It much messier than the photos show, more equipment as well.

Tom

Thanks for the kind comments regarding the shop. It much messier than the photos show, more equipment as well.

Tom

- Joined

- Oct 20, 2010

- Messages

- 913

- Reaction score

- 132

I have added more wonderful tools to burden my kids with when I am gone. As well as use while still here.

View of the shop

.

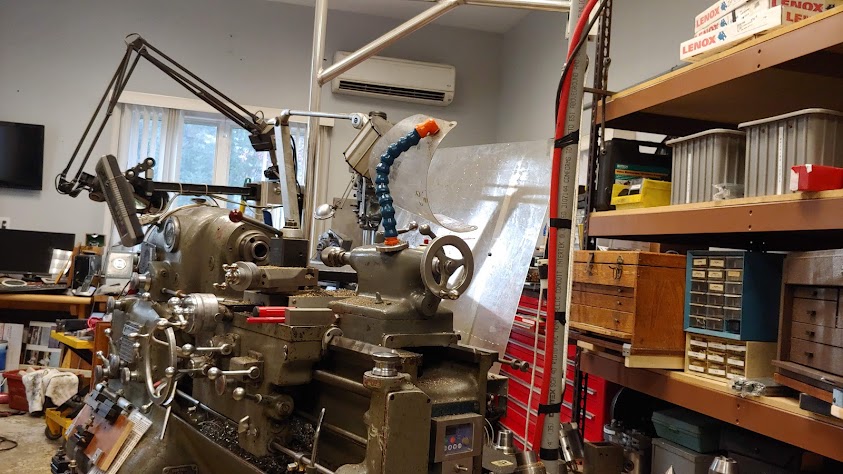

The shelves used to be stocked with a decade worth of business records, all gone now. There are 4 roll out shelves currently, with enough slides for half dozen more.

The lift for the lathe lines up with the shelve for the chucks. The wood tool box was made by my Dad 60 years, I was 6 at the time, special.

View of the shop

.

The shelves used to be stocked with a decade worth of business records, all gone now. There are 4 roll out shelves currently, with enough slides for half dozen more.

The lift for the lathe lines up with the shelve for the chucks. The wood tool box was made by my Dad 60 years, I was 6 at the time, special.

Last edited:

Perfect. Don't change a thing. My shop is similar and I would feel comfortable in your shop. Best of all, it's a Grandpa's shop where we can share skills, safety and creativity with our grandchildren. It's where they can develop the confidence to 'fix' anything. Congrats and thanks for sharing.

MachineTom I like that lathe of yours can you tell us what make it is..

- Joined

- Oct 20, 2010

- Messages

- 913

- Reaction score

- 132

That is a Monarch 10EE. That originally had a Tube drive, BIG vacuum tubes made DC current to drive monster 5hp motor. I replaced with a 5hp motor VFD drive.

The lathe will swing 12", but rated as a 10", rather stout 3200lbs.

Love It.

First photo shows the Surface Grinder, as well as a Myford Cylindrical grinder.

The lathe will swing 12", but rated as a 10", rather stout 3200lbs.

Love It.

First photo shows the Surface Grinder, as well as a Myford Cylindrical grinder.

Because I have a fusion at C3C4 in the neck, I have limited movement in my neck. I was using mirrors often to see things. Now a cell phone is quite useful to look at the compound slide radial graduations or looking in a bore or looking at the dial indicator on a mill when used in mirror mode.

Another tool that is useful is a bore scope . It has a camera on a stick and is useful as I can no longer move my head around to look at things like I used to.

Another tool that is useful is a bore scope . It has a camera on a stick and is useful as I can no longer move my head around to look at things like I used to.

stackerjack

Well-Known Member

- Joined

- Sep 12, 2014

- Messages

- 80

- Reaction score

- 12

One thing I find useful, when using my battery operated drill. In order to keep the hole perpendicular, I have fitted a small spirit level to the top of the drill. As I'm drilling the hole, I look down from above, which gives me correct left/right angle and the spirit level tells me the correct up/down angle.

Jack

Jack

Similar threads

- Replies

- 2

- Views

- 10K