ROY@ESUACE

New Member

- Joined

- Jul 20, 2011

- Messages

- 4

- Reaction score

- 0

Hi all:

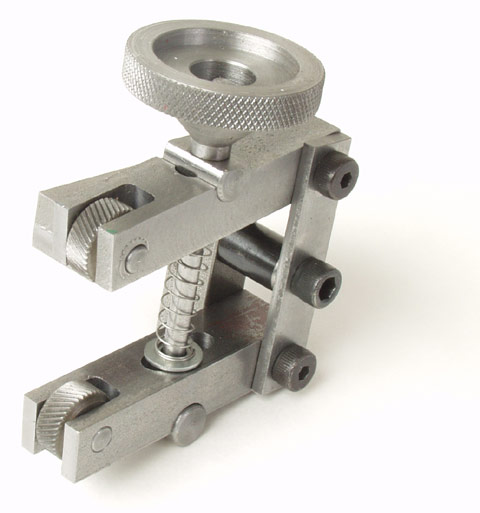

Roy from Maryland, USA here. I'm an inexperienced lathe owner(Craftsman 6") but dream of building an IC engine some day. I'd like to get a QCTP for my lathe but the two OXA series 000s listed on LMS says you need 5/8" from compound to spindle center on one ad and 3/4" on another for the OXA 000. One is listed as TORMACH, and the other is not named, but the ads look the same. SEE #3048 on http://www.littlemachineshop.com/info/qctp.php Here's my question - I measure 17/32" from the top of my compound to the dead center point in my spindle. Can I use the OXA and just set the tool holders a little lower on the post, or does this cause some other problem? I like OXA because it's steel, and wedge-locked, not plunger. There is a T6 aluminum one offered by LMS, but the OXA, though a little more money, looks like a better deal.

Thanks in advance for your help

Roy

Roy from Maryland, USA here. I'm an inexperienced lathe owner(Craftsman 6") but dream of building an IC engine some day. I'd like to get a QCTP for my lathe but the two OXA series 000s listed on LMS says you need 5/8" from compound to spindle center on one ad and 3/4" on another for the OXA 000. One is listed as TORMACH, and the other is not named, but the ads look the same. SEE #3048 on http://www.littlemachineshop.com/info/qctp.php Here's my question - I measure 17/32" from the top of my compound to the dead center point in my spindle. Can I use the OXA and just set the tool holders a little lower on the post, or does this cause some other problem? I like OXA because it's steel, and wedge-locked, not plunger. There is a T6 aluminum one offered by LMS, but the OXA, though a little more money, looks like a better deal.

Thanks in advance for your help

Roy

Last edited: